Electro-optical yarn sensor

A sensor and yarn technology used in optical device exploration, textile and papermaking, looms, etc. to improve reading quality and compensate for manufacturing and assembly tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

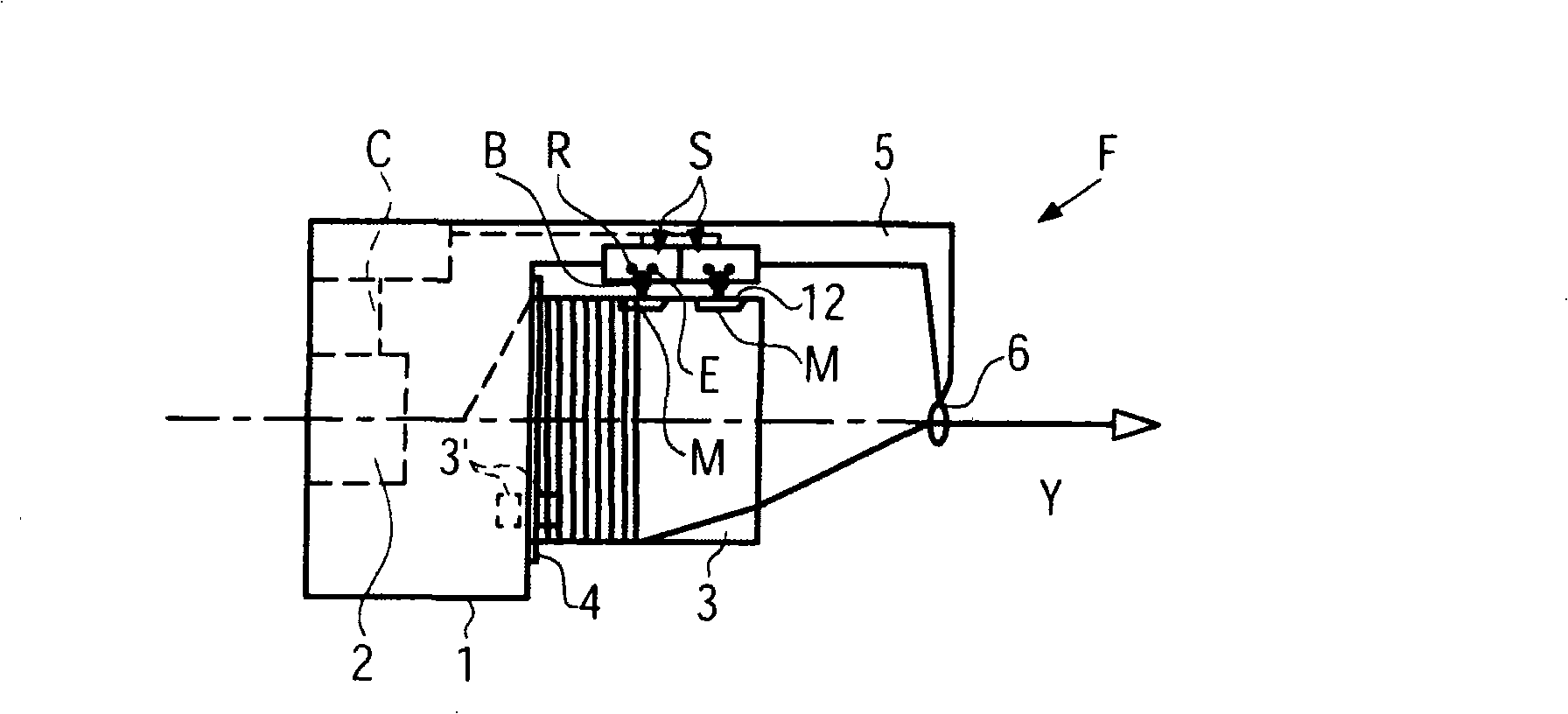

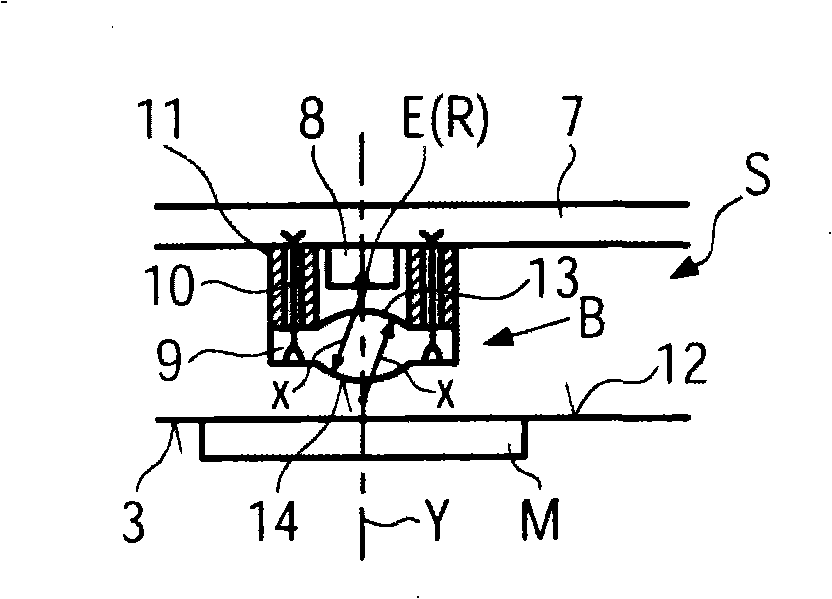

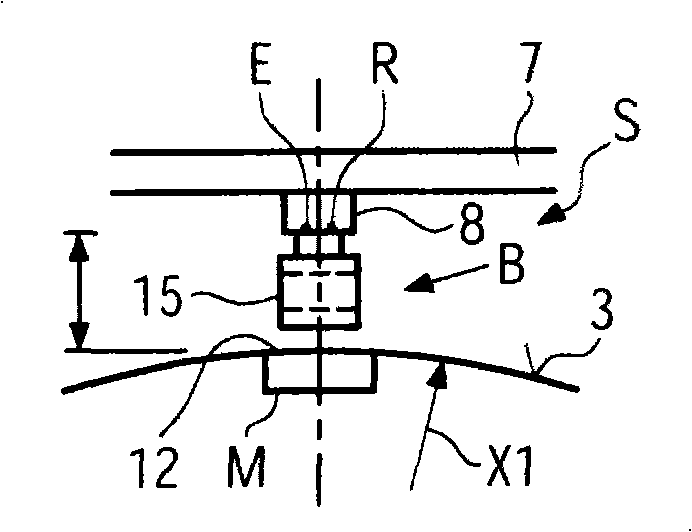

[0032] figure 1 The yarn feeding device F in a loom, such as a weft yarn feeding device of a loom or a knitting yarn feeding device of a knitting machine, includes a housing 1 that includes an electric motor 2 and a drum-shaped yarn storage body 3 . The storage body 3 is rotatably supported on a not shown drive shaft, however, is hindered to rotate with the drive shaft (fixed storage drum) by a co-operating magnet 3'. In an alternative not shown, the yarn feeding device can alternatively be equipped with a rotatable yarn storage body. The drive shaft drives a winding element 4 which winds the yarn Y inserted into the yarn feeding device F from the left onto adjacent windings on the periphery of the yarn storage body 3 . The yarn is then unwound from the foremost winding on the storage body 3 and optionally passed axially through the exit hole 6 . The housing has a housing support 5, in the embodiment shown, in which two photoelectric yarn sensors S are fixedly mounted, said...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com