A magnetic liquid micro pressure difference sensor with a composite magnetic core

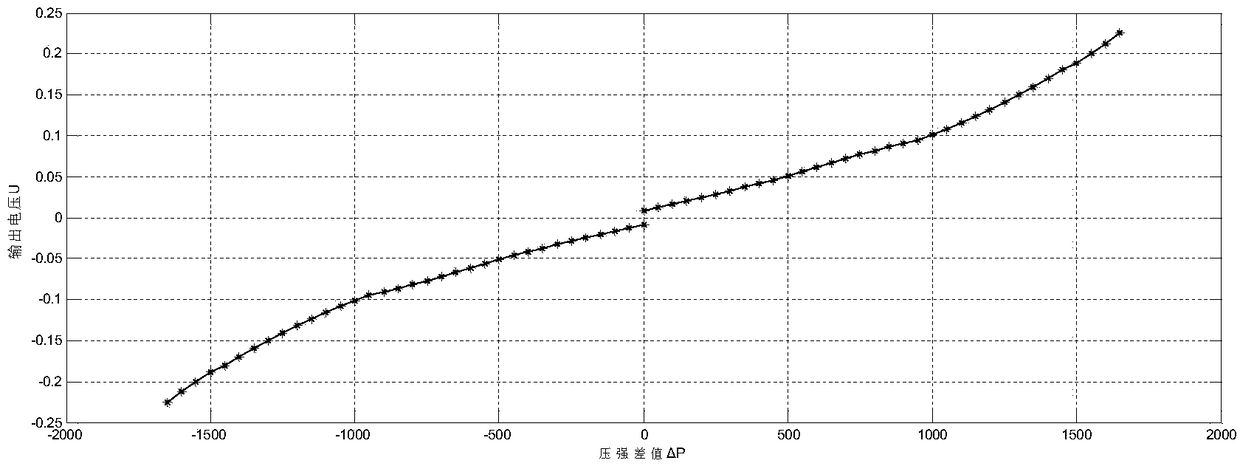

A micro differential pressure sensor, magnetic liquid technology, applied in the pressure difference measurement between multiple valves, fluid pressure measurement, instruments and other directions, can solve the problems of fixed volume, weak signal, and the distance between the input gas port cannot be flexibly changed, etc. Achieve the effect of obvious output electrical signal and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] The present invention will be further described with accompanying drawing as specific embodiment:

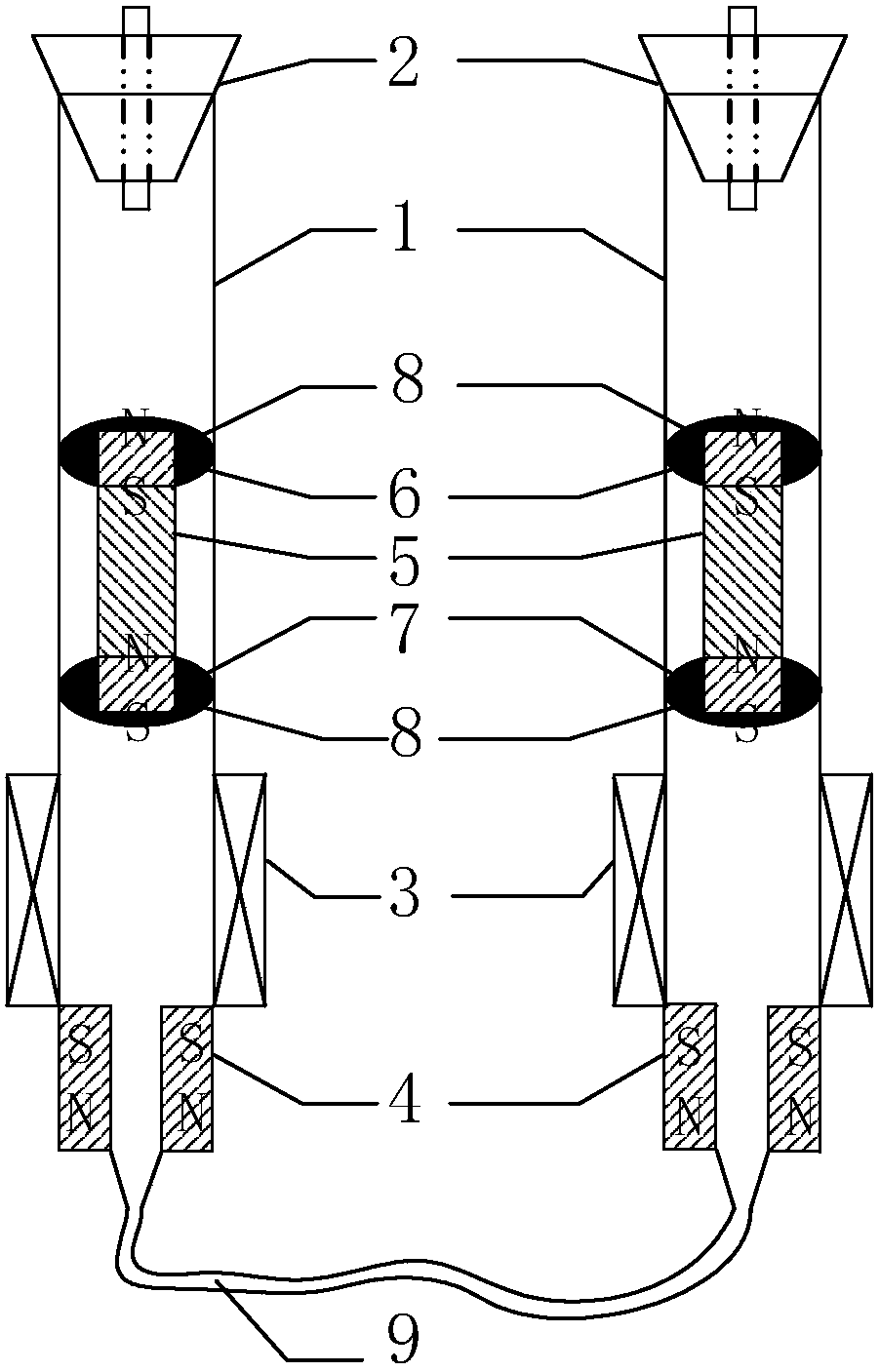

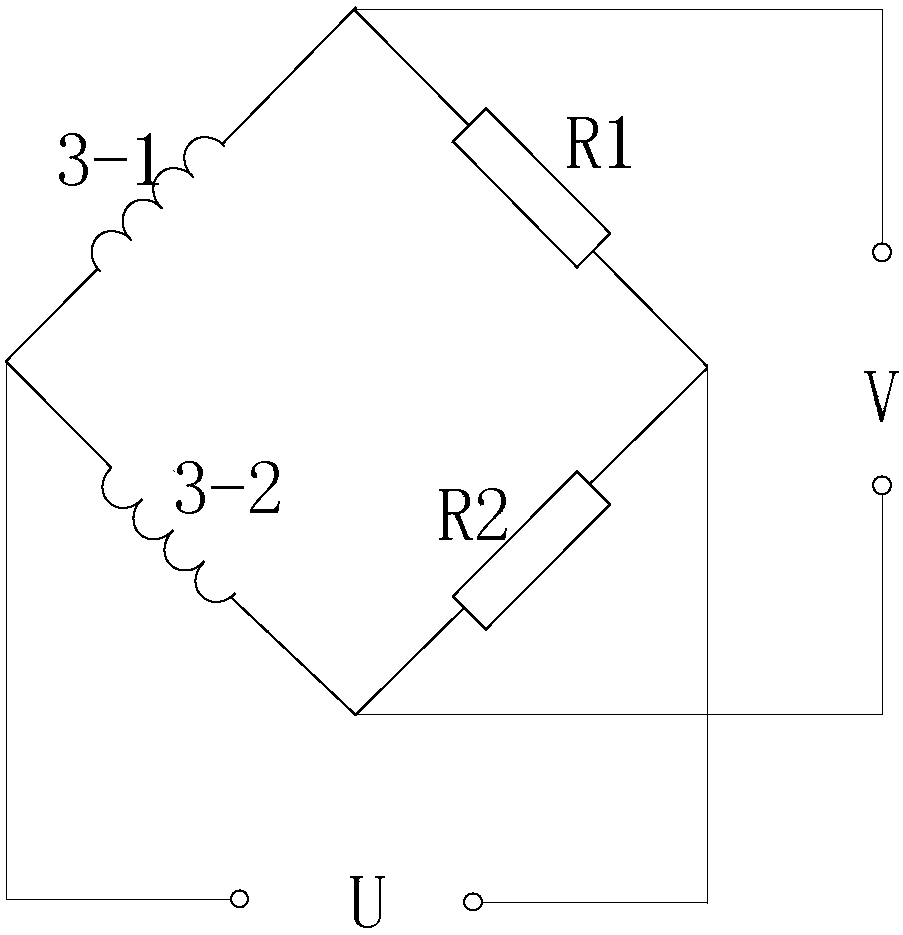

[0026] A magnetic liquid micro-pressure difference sensor with a composite magnetic core according to the present invention is as follows: figure 1 As shown, including the sensor body and the bridge circuit part;

[0027] Wherein, the sensor main body includes the same two parts, and each part includes a plexiglass tube 1, a rubber plug 2, a coil 3, an annular permanent magnet 4, a composite magnetic core and a magnetic fluid 8; wherein, the plexiglass tube 1 includes a thick diameter Part and small diameter part; the top of the thick diameter part of the upper part is plugged with a rubber plug 2, the inner side of the middle part is a composite magnetic core, and the outer side of the lower end is wound with a coil 3; the two ends of the composite magnetic core are saturated with magnetic liquid 8 (magnetic liquid 8 makes The comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com