Combined type casting box used for founding flat-bottom same-series castings

A combined technology of the same series, applied in casting and forming equipment, mold boxes, molds, etc., can solve the problems of long time and difficulty in sand box production, and achieve the effect of shortening production time, improving efficiency and reducing capital investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

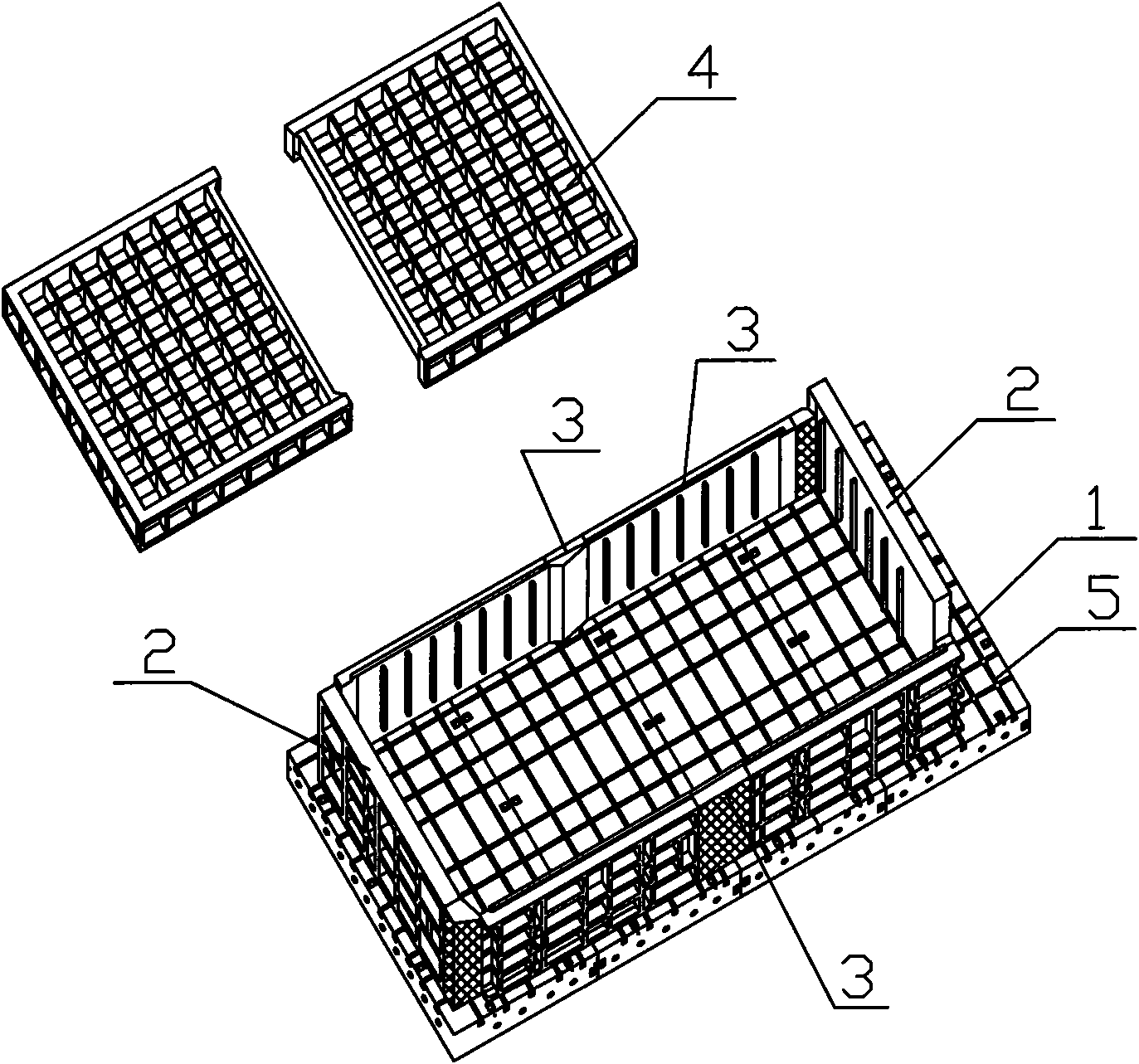

[0016] Such as figure 1 , image 3 and Figure 4 As shown, it is a combined sand box for the same series of castings with a flat bottom of the present invention, which is a type a, including a bottom plate 1 of a large flat structure, several general-purpose side plates one 2, several side plates two 3 of the model a and installed on the side plate The top plate 4 on the top, the bottom plate 1 is provided with a number of slots 5 corresponding to the position of the side plates of the model a sand box, the bottom of the side plate one and the second side plate is provided with the ribs 6 corresponding to the slots, and the side plate one And the second side plate is connected to the card groove by the card rib, the card bar 6 is a straight bar structure, and the top surface of the card bar is provided with an installation-assisting slope 7, and the card slot is a criss-cross grid or X-shaped net lattice. The above-mentioned clamping ribs can also be set in a cross shape or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com