Reducing pipe cleaning valve

A technology for pigging and pigging, which is applied in valve details, multi-port valves, valve devices, etc., can solve the problems of troublesome and time-consuming operation, occupying a lot of space, and long construction period, so as to reduce maintenance costs and reduce the diameter of pigging. The effect of simplifying the method and saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

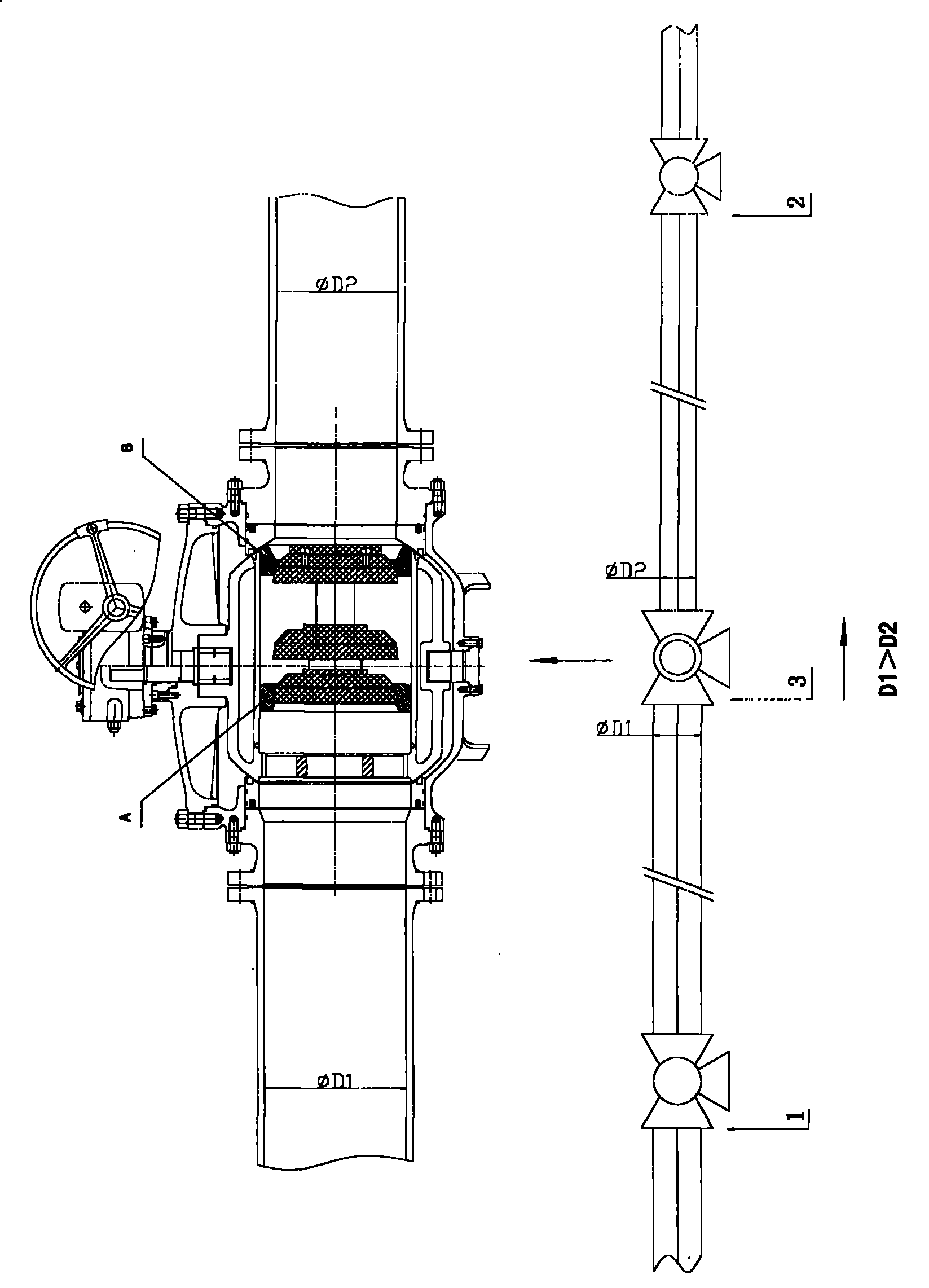

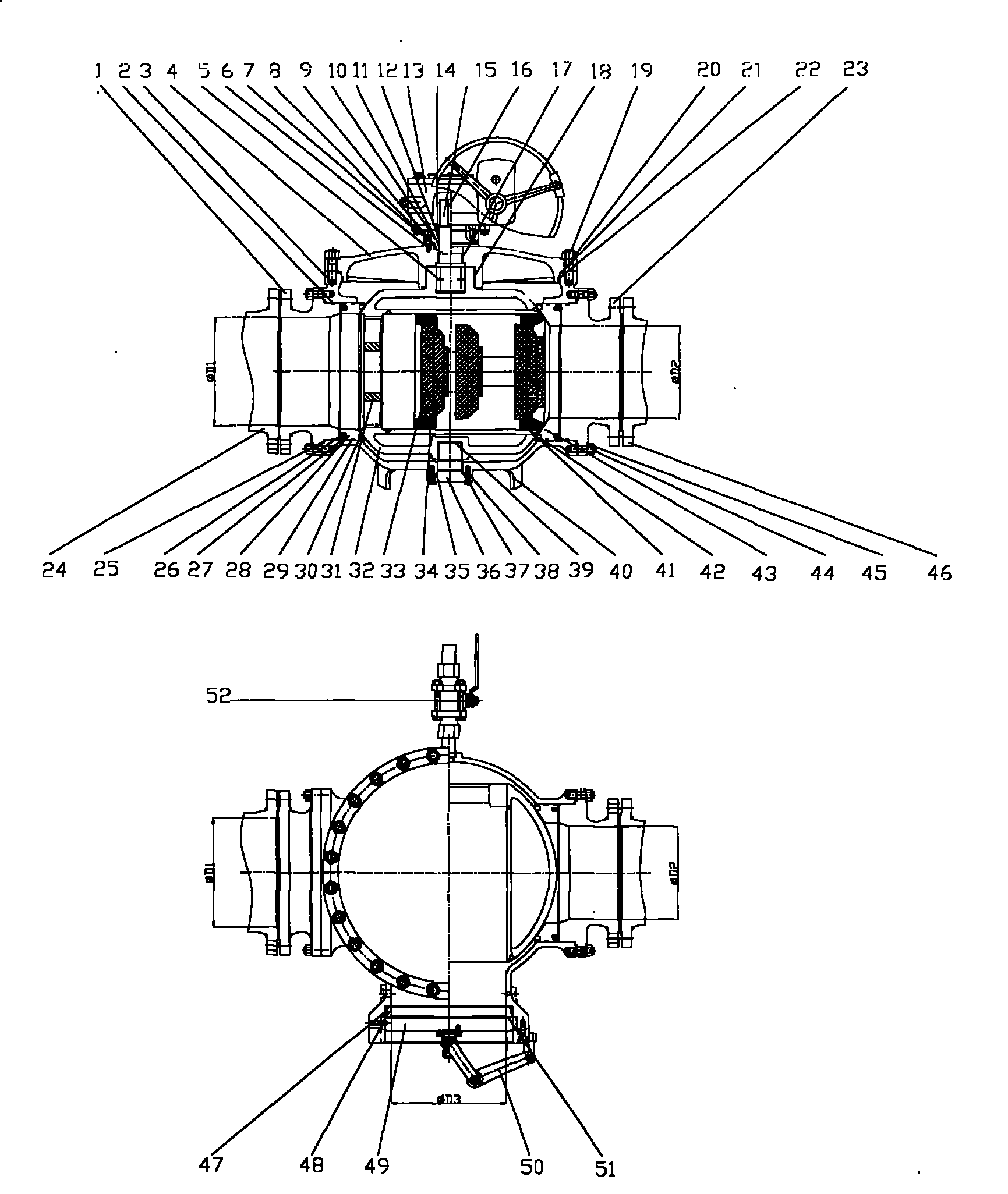

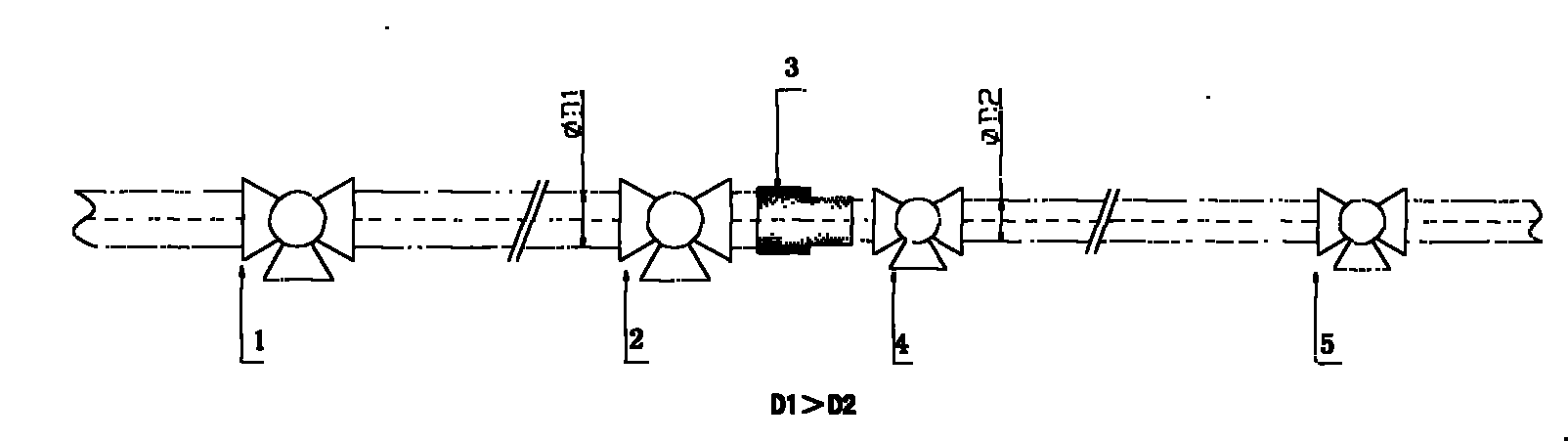

[0029] The valve body is integrally forged or cast, and the valve body is connected with the upstream flange and downstream flange by bolts, and the gasket and O-ring are used to seal; when the diameter of the upstream pipe is larger than that of the downstream pipe, the inner diameter of the downstream flange is larger than that of the upstream flange. The inner diameter is small; when the diameter of the upstream pipe is smaller than that of the downstream pipe, the inner diameter of the downstream flange is larger than that of the upstream flange. The ball is located in the center of the valve body and is positioned by the base and the valve cover. The valve stem with the anti-flying structure fits the ball in a flat square, and the valve stem is not subject to shear force and bending moment; there is a friction-reducing sliding device between the valve stem and the valve cover. Bearings reduce frictional torque; the seal between the valve stem and the branch pipe uses packi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com