Fast measuring method of tobacco shred mixing ratio

A technology for rapid determination and cut tobacco, which is applied in the measurement of scattering characteristics, etc., can solve the problems of heavy workload, complex modeling process, poor accuracy of results, etc., and achieve the effect of less detection instruments, simple process method, and rapid detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

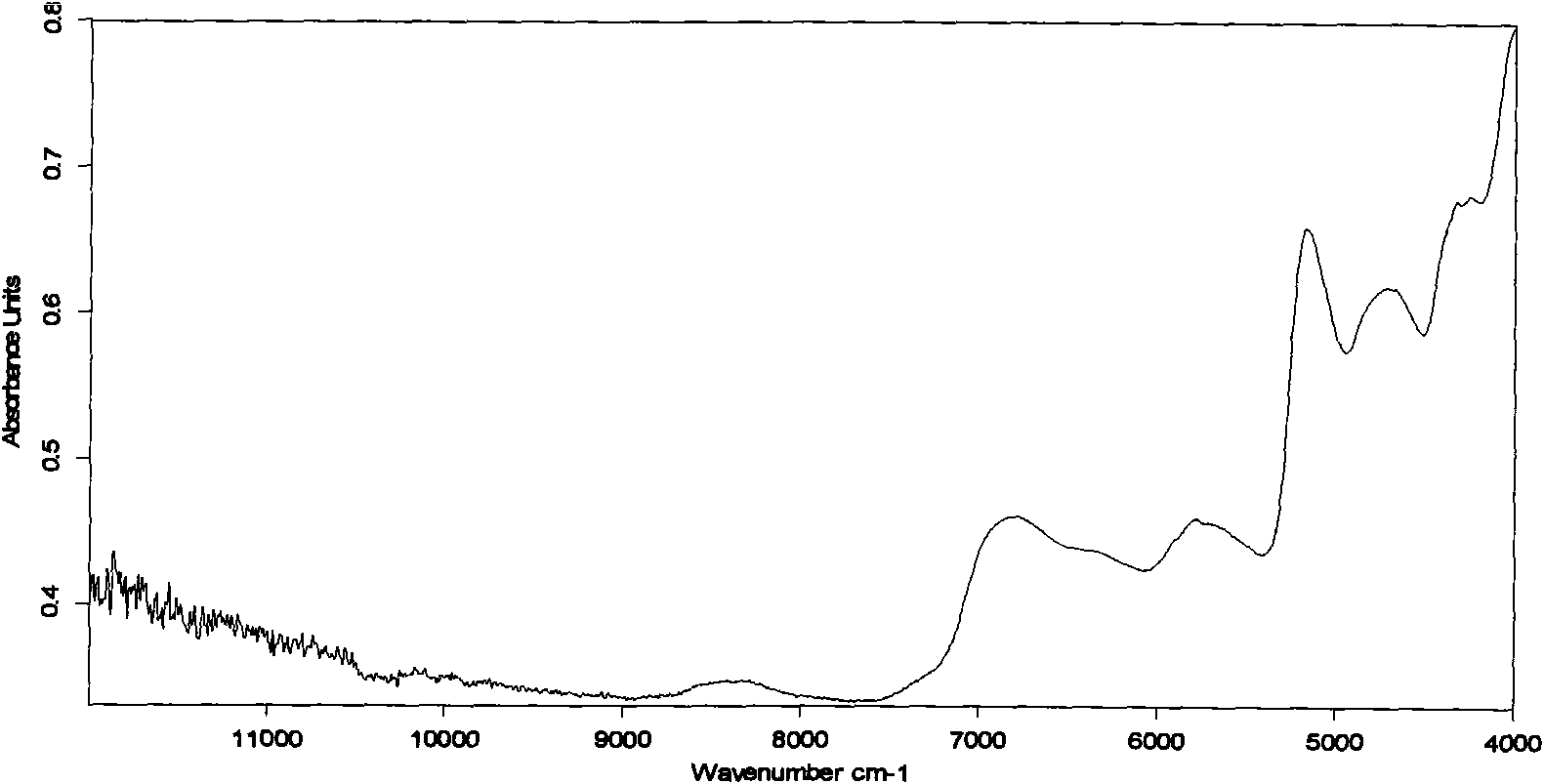

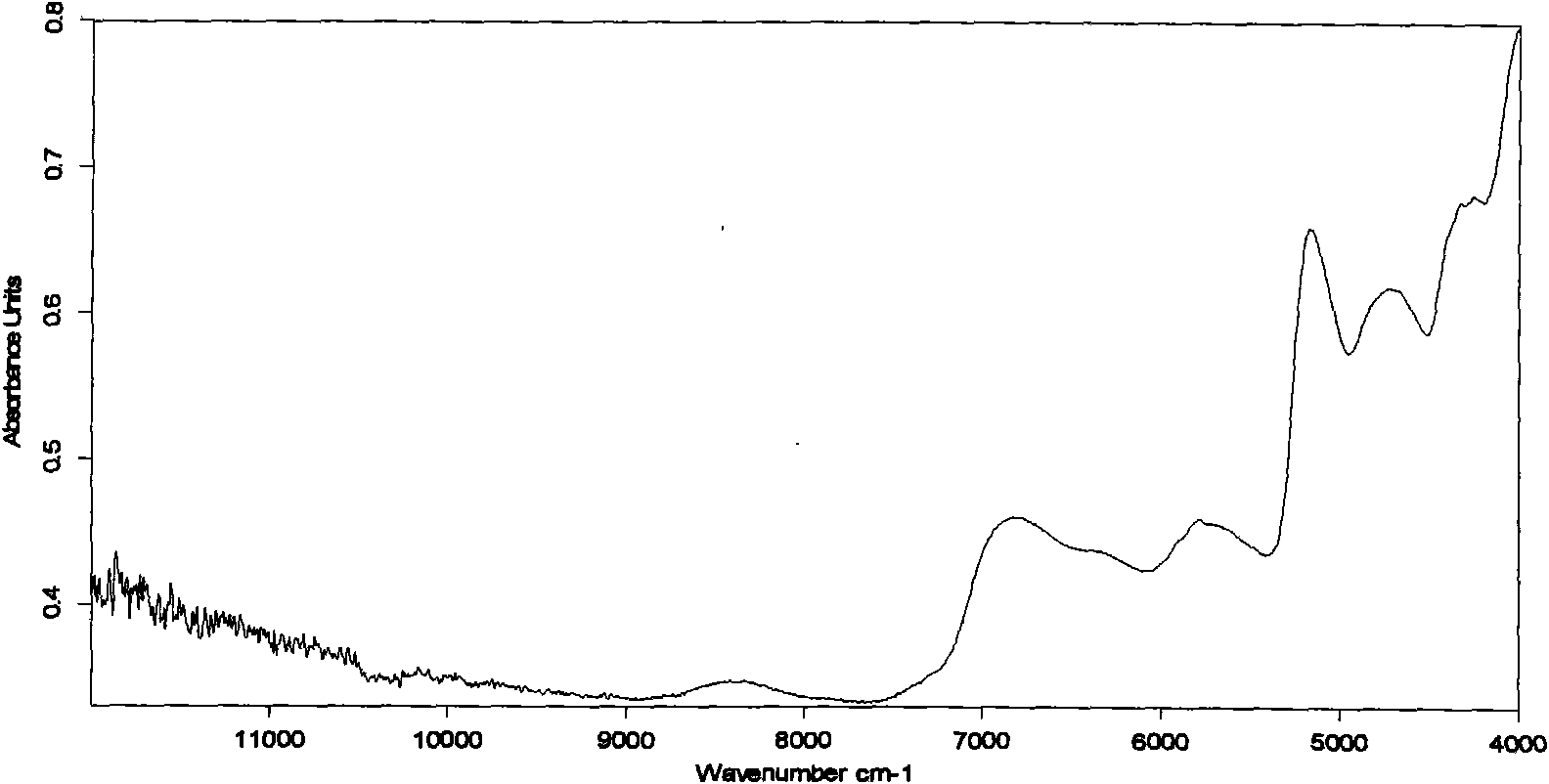

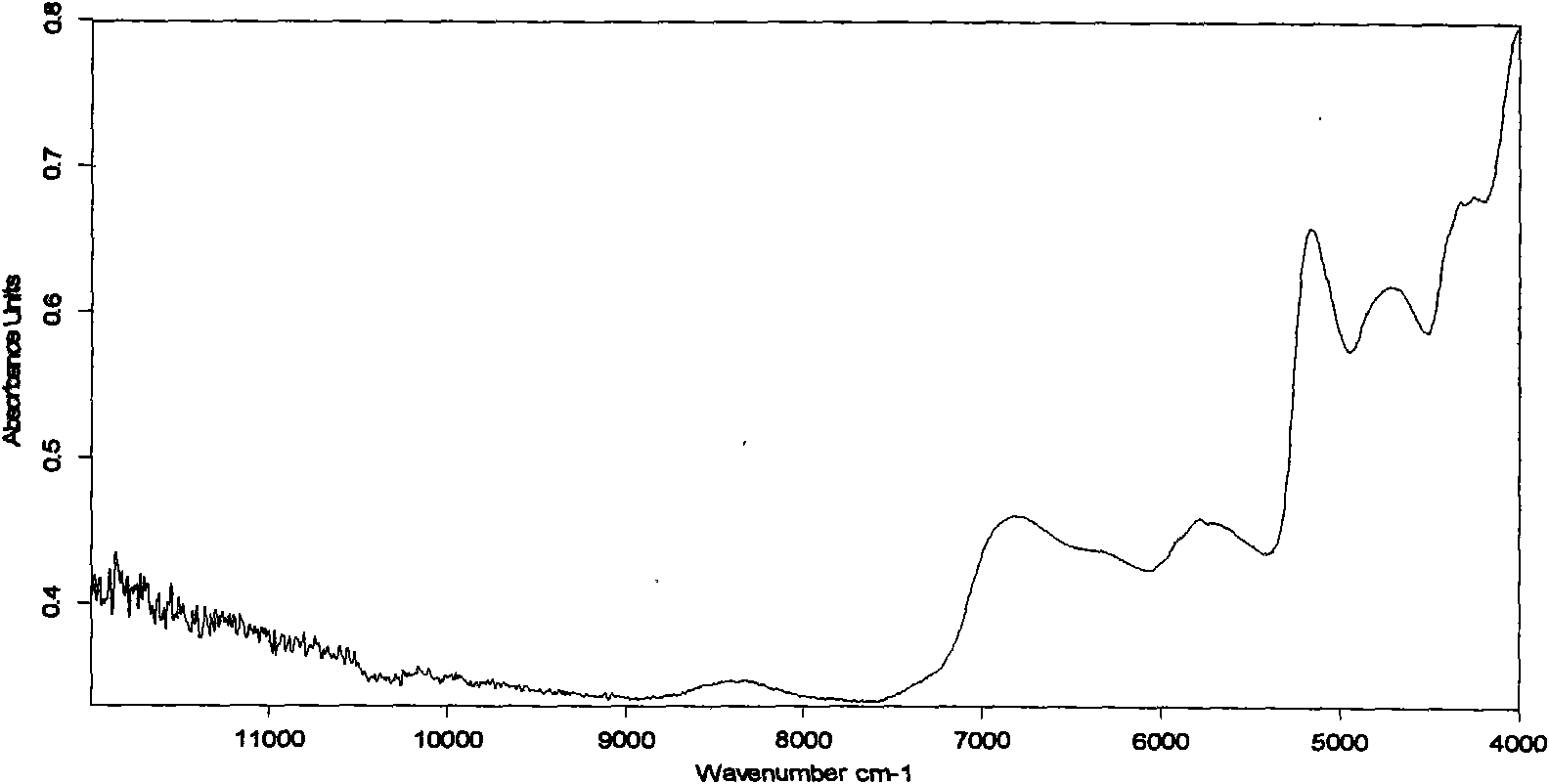

Image

Examples

specific Embodiment approach 2

[0064] The present invention will be further elaborated below.

[0065] Take a brand of cigarettes as an example, the shredded tobacco of this brand cigarette is composed of shredded leaves, cut stems and shredded slices. Take an appropriate amount of shredded leaves, shredded stems, shredded slices and 5 finished tobaccos of the brand used in a certain batch of cigarettes of the brand, and go through steps 9 to 12 in sequence:

[0066] After step 9 is crushed, pass through a 40-mesh sieve to make No. 1 finished shredded tobacco sample to be tested, No. 2 finished shredded tobacco sample to be tested, No. 3 finished shredded tobacco sample to be tested, No. 4 finished shredded tobacco sample to be tested, No. 5 finished shredded tobacco sample to be tested, Samples of shredded leaves to be tested, samples of shredded stems to be tested, samples of shredded shreds to be tested.

[0067] Step 10 uses No. 1 finished shredded tobacco sample to be tested, No. 2 finished shredded t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com