Elevator damper assembly

A technology of dampers and components, used in elevators, transportation and packaging in buildings, etc., can solve problems such as reducing the ability of vibration isolators to reduce noise and vibration, excessive compression of vibration isolators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

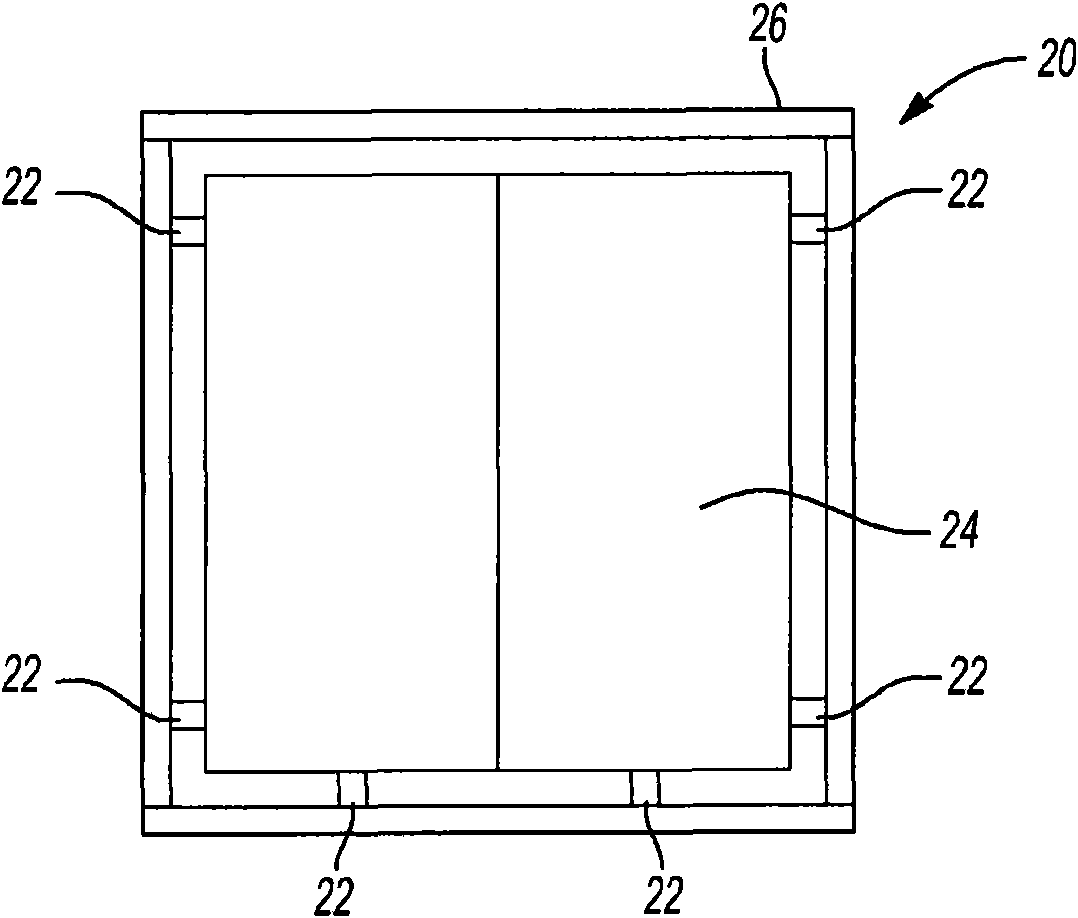

[0013] figure 1 Selected portions of elevator system 20 are shown schematically. In this example, a plurality of damper assemblies 22 are positioned between an elevator cab 24 and an associated frame 26 that supports the cab 24 and allows it to move within the tunnel in a known manner. The damper assembly 22 provides vibration isolation so that persons within the cabin 24 will not need to experience the vibrations experienced by the frame 26 . The damper assembly 22 also provides isolation from structure-borne noise that may be generated due to frame 26 vibrations, operation of the elevator machine, or from the surrounding environment of the cabin 24 .

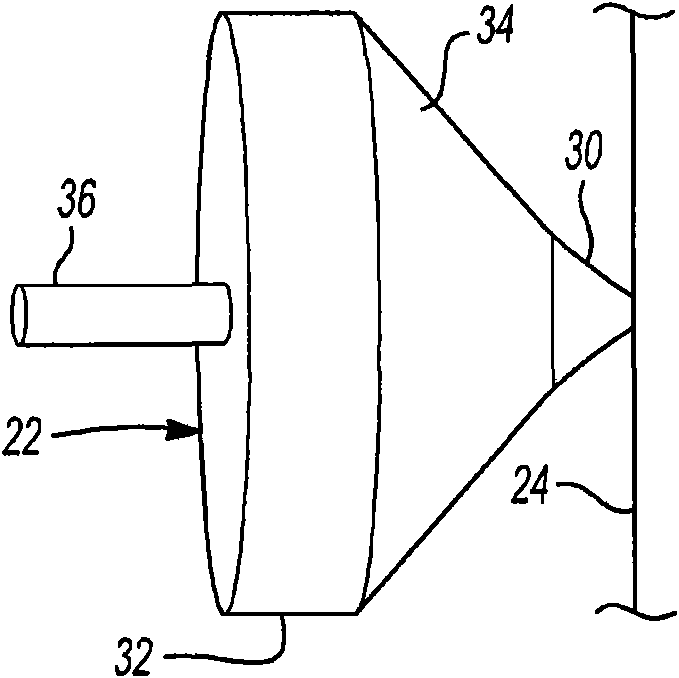

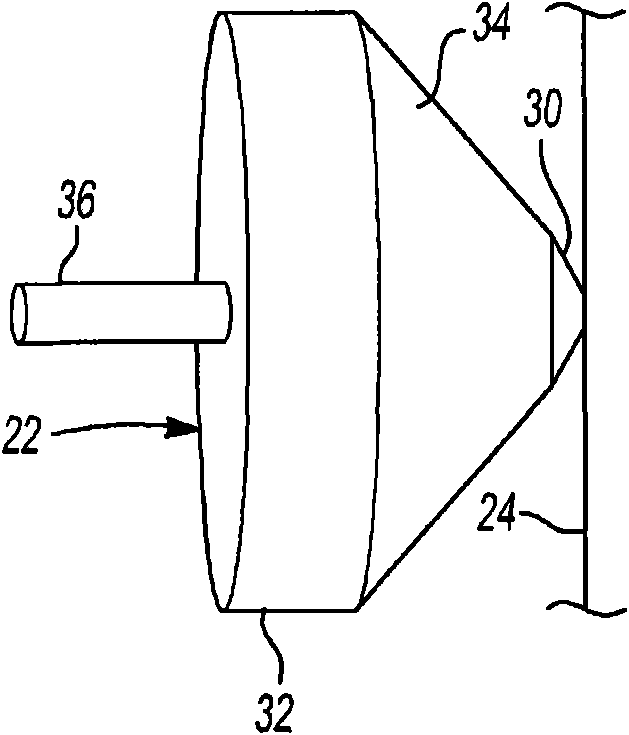

[0014] Damper assembly 22 includes a resilient member that deflects in response to loads associated with relative motion between pod 24 and frame 26 . The damper assembly 22 serves to isolate the capsule 24 from vibrations that would be transmitted to the capsule 24 if there were a rigid connection between the frame 26 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com