Seat drilling machine

A technology for drilling machines and chairs, which is applied to drilling machines, fixed drilling machines, wood processing equipment, etc. It can solve the problems of troublesome positioning, difficult batch processing, and low dimensional accuracy, so as to achieve high work efficiency and prevent workpieces from vibrating , the effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

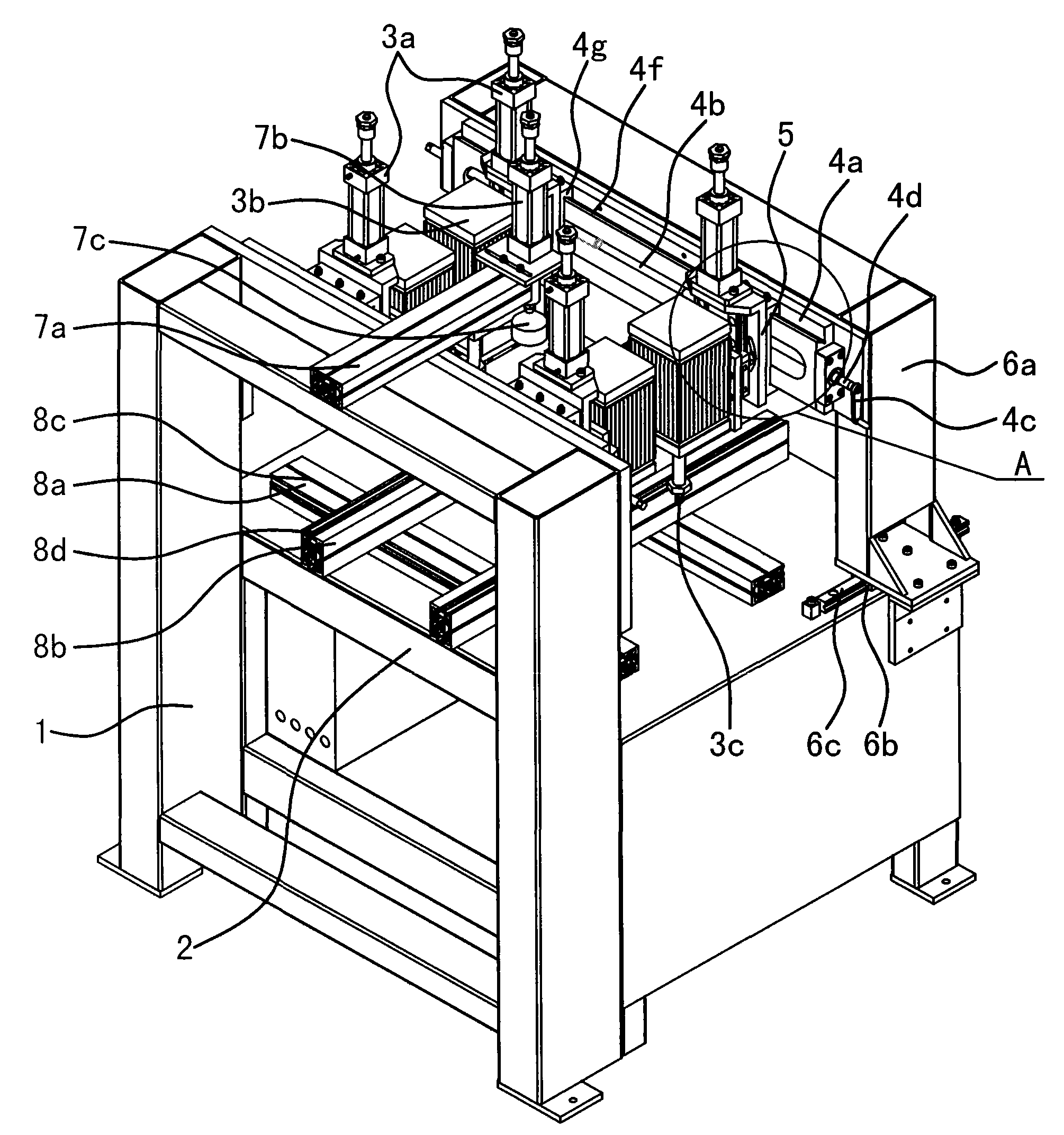

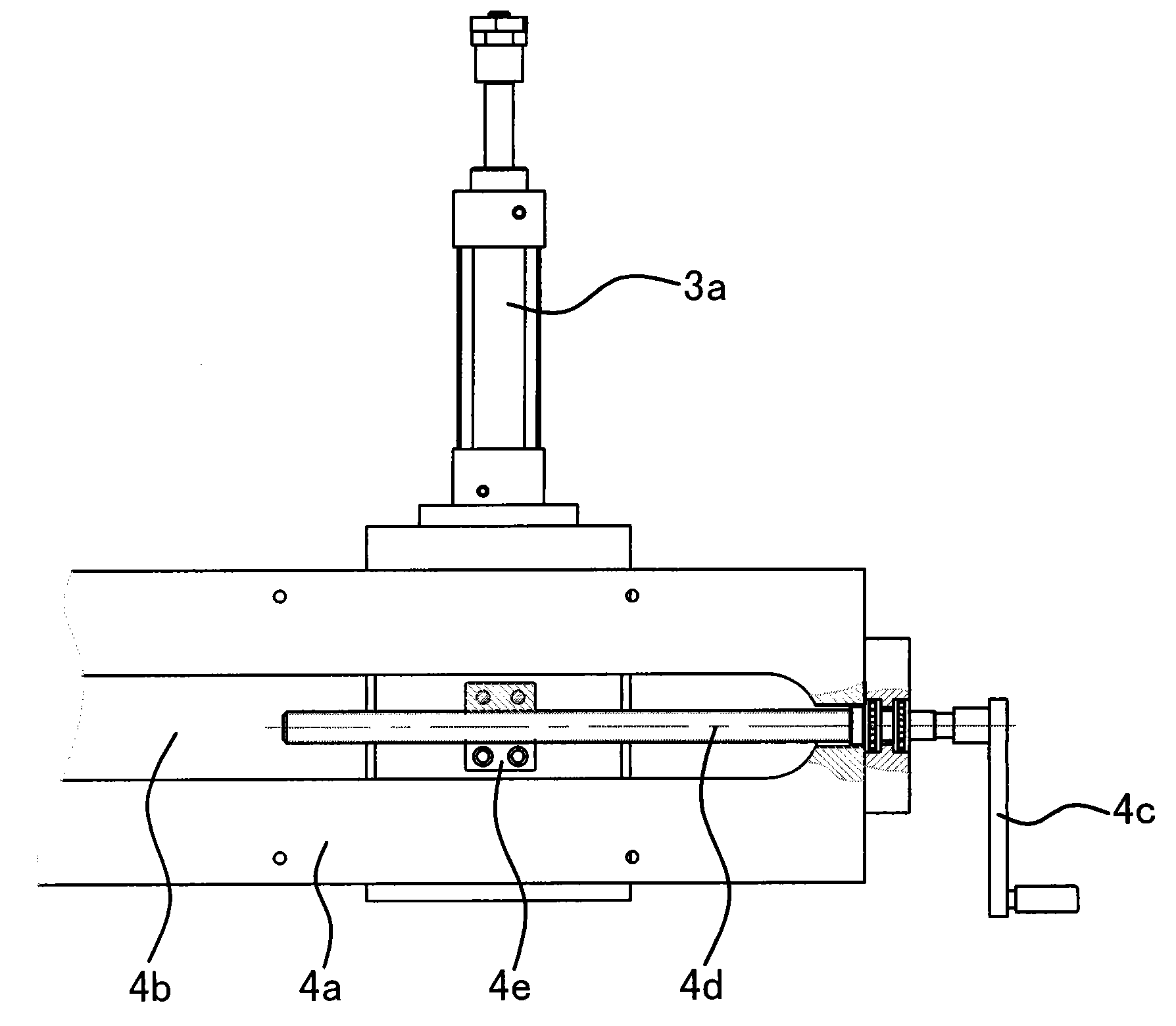

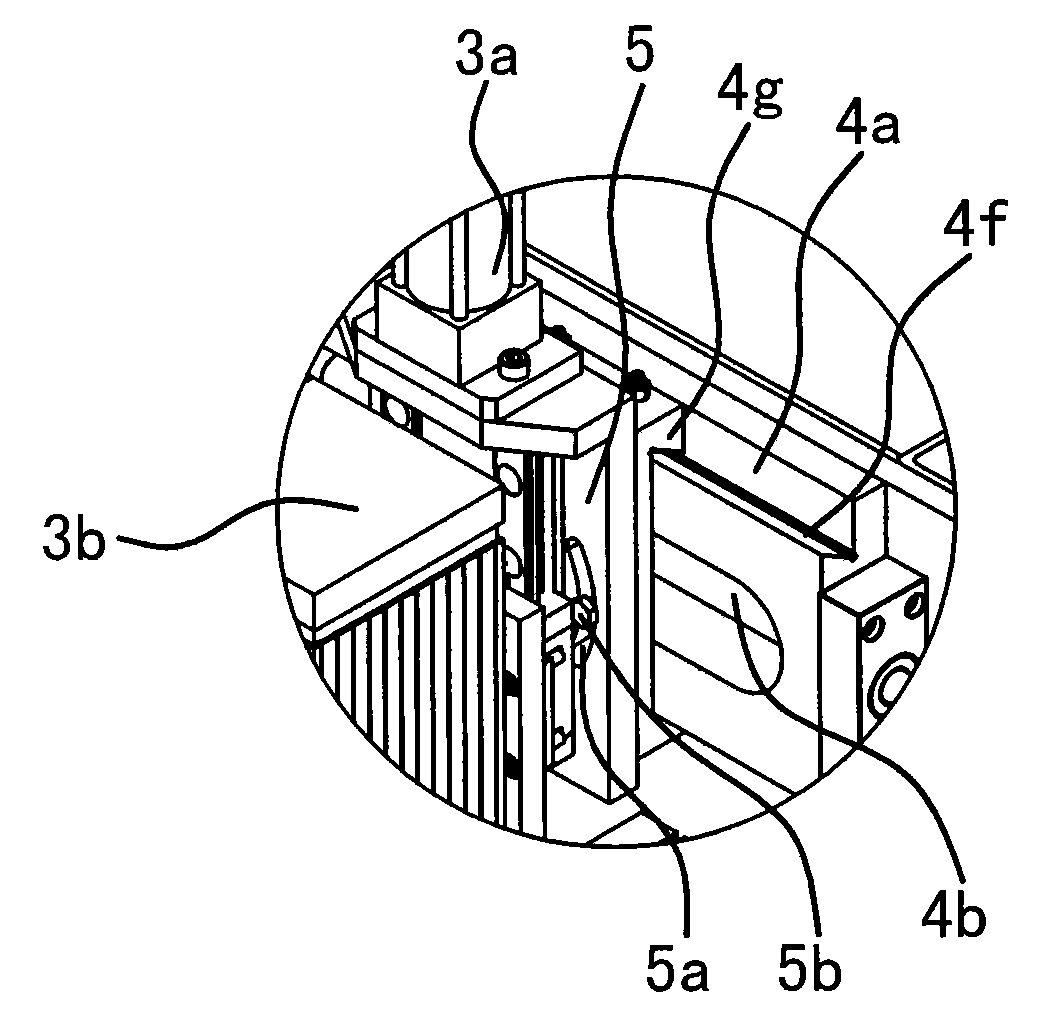

[0028] Such as figure 1 , Figure 4 As shown, this seat drilling machine is mainly used for drilling wooden seat boards and backrests. Its structure includes a bed frame 1 and a workbench 2 fixed on the bed frame 1 for placing workpieces. Four identical drilling devices, and these four drilling devices are arranged in parallel in two rows, each row is provided with two, each drilling device includes a vertically arranged driving cylinder 3a, and the piston rod of the driving cylinder 3a is fixedly connected to the vertical The motor 3b that is arranged straightly, the output shaft of motor 3b connects drill bit 3c, is respectively provided with the lateral adjustment mechanism that can make this drive cylinder translate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com