Drain structure of air cleaner for motorcycle

A technology for air filters and motorcycles, which is applied to fuel air filters, vehicle components, and power plant gas intake, etc., can solve the problem of increased production costs, poorer design freedom of motorcycle casings, and control flexibility. It can reduce assembly work, improve design freedom, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

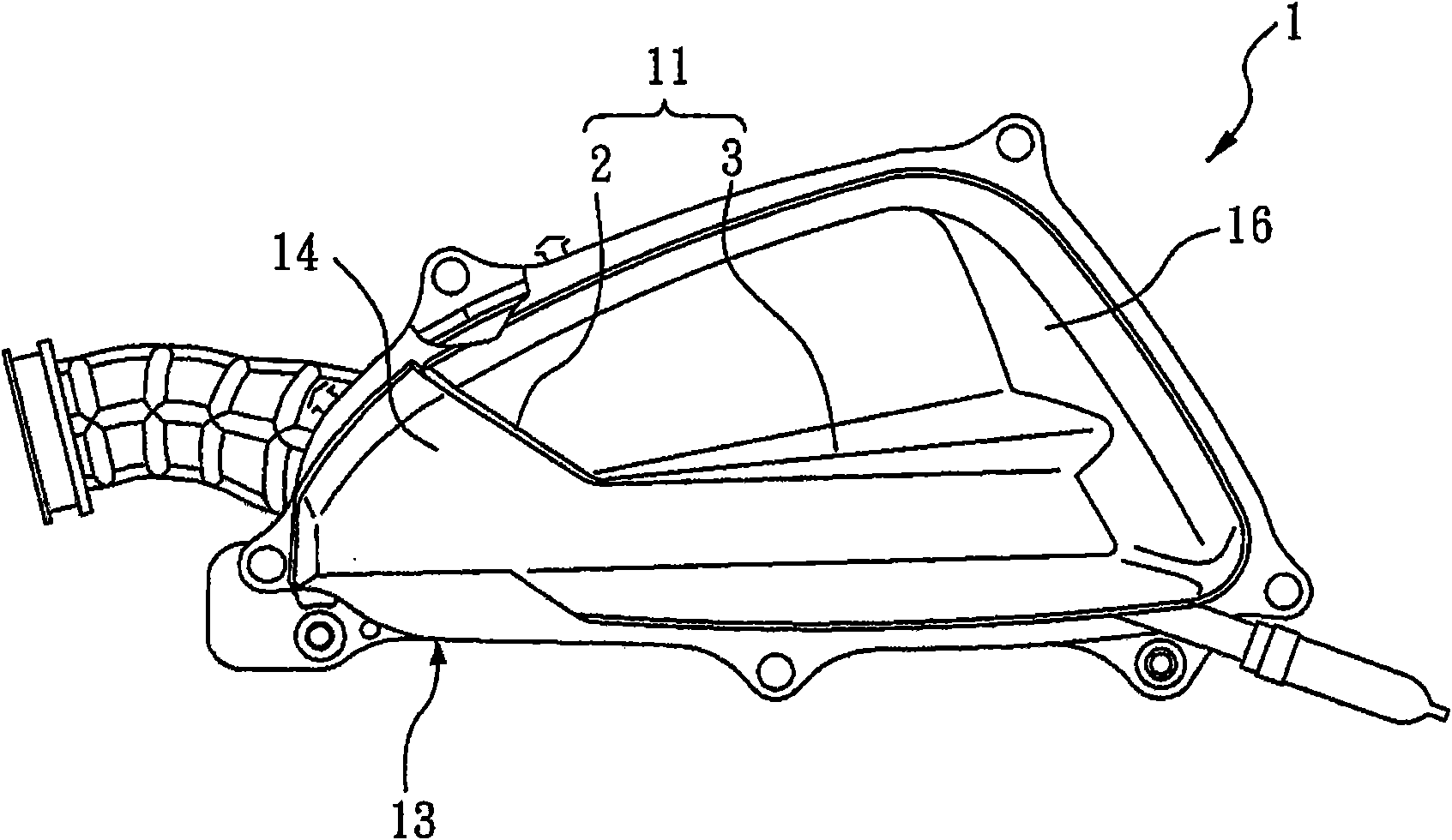

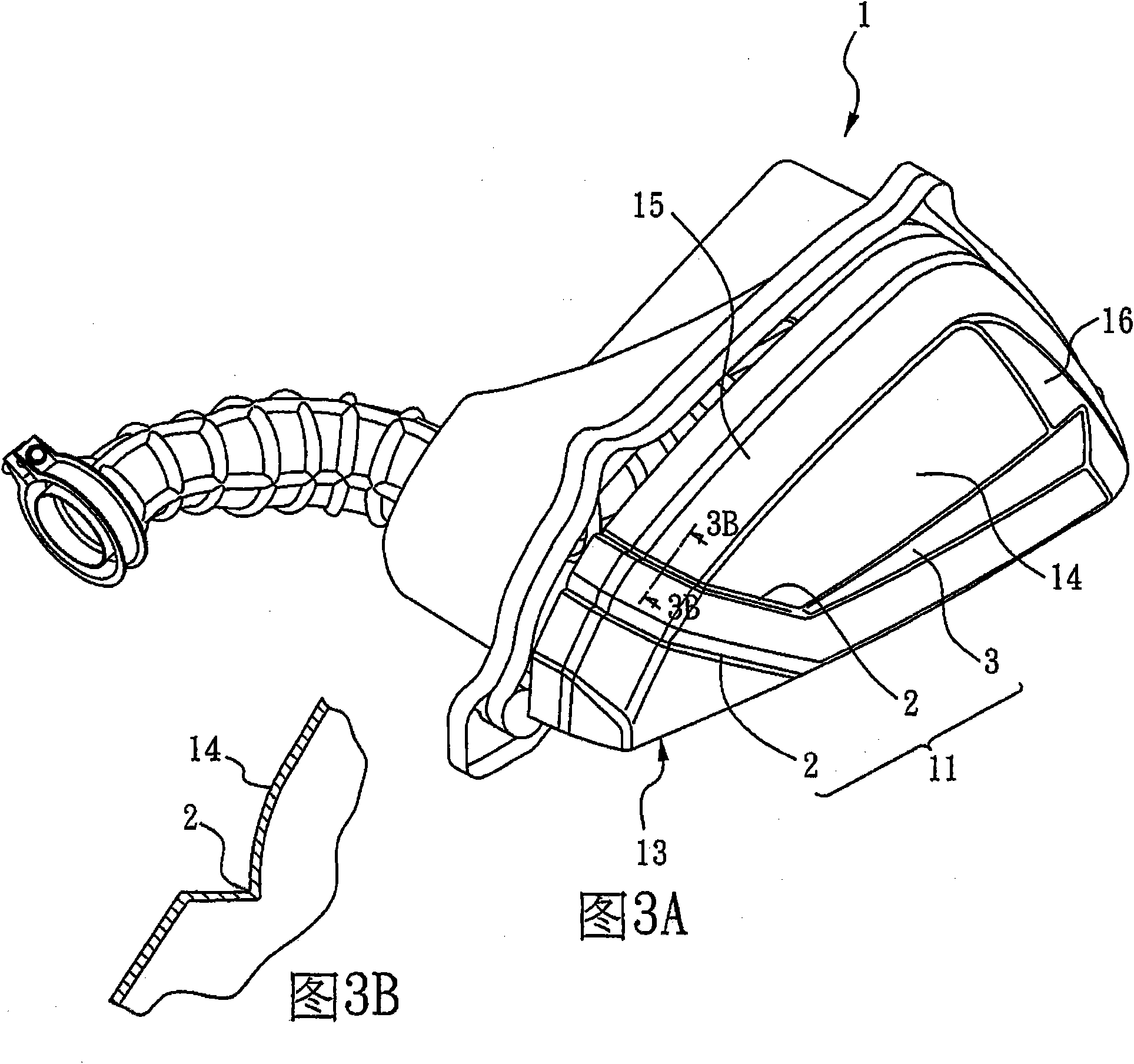

[0025] Hereinafter, the embodiments of the present invention will be described in detail with reference to the drawings.

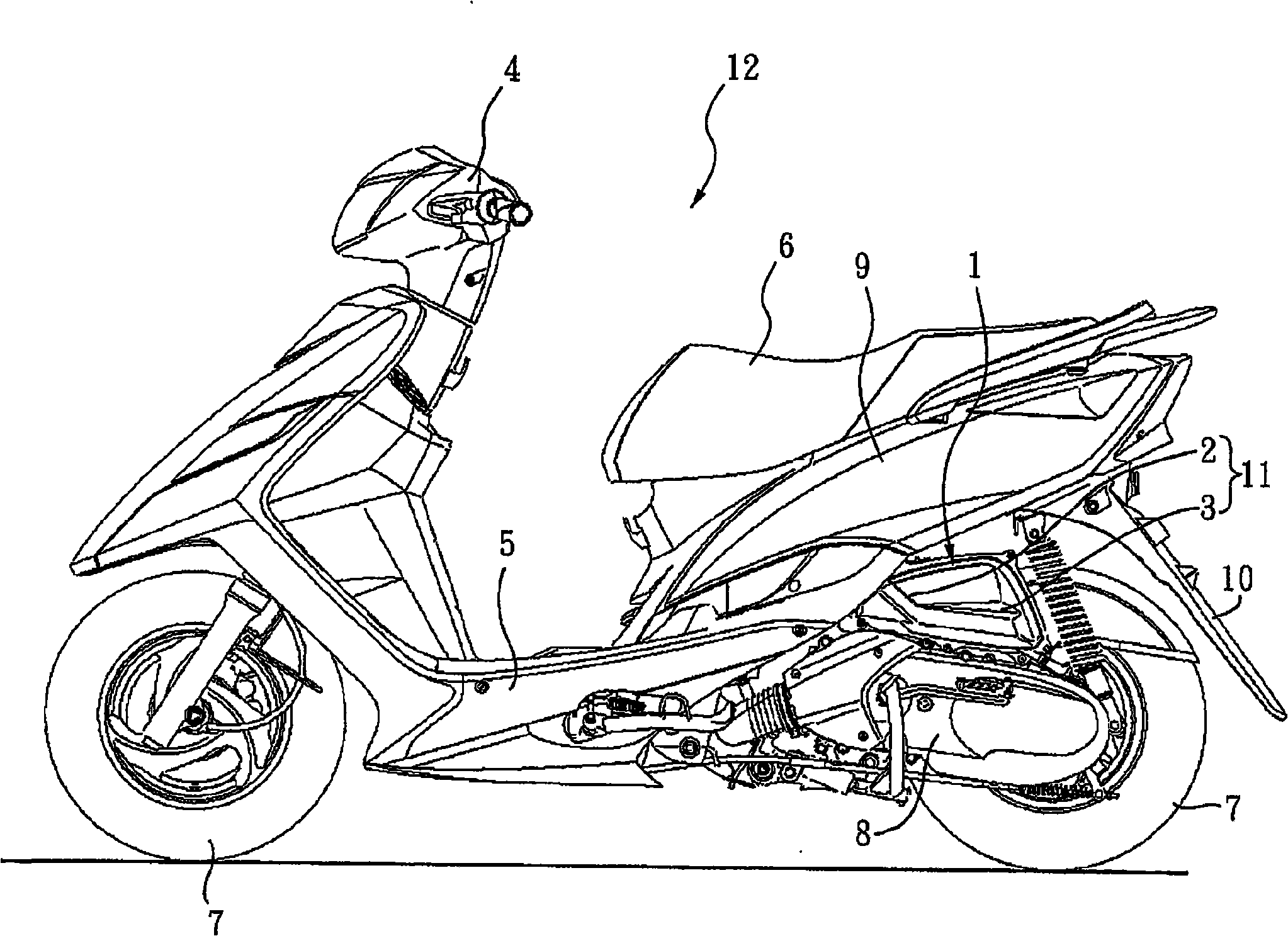

[0026] figure 1 It is a side view of a motorcycle including the drainage structure of the air cleaner for motorcycle of the present invention. figure 1 Although it is shown that the drainage structure 11 of the air cleaner for motorcycles of the present invention is applied to a scooter-type motorcycle, the present invention is not limited to be applied to a scooter-type motorcycle, and may also be other types of motorcycles. Vehicles, such as gear-mounted motorcycles, and powered vehicles. Powered vehicles are, for example, all-terrain vehicles (ATV) and snowmobiles.

[0027] Such as figure 1 As shown, a side view of a motorcycle 12 having a drainage structure 11 of an air cleaner for a motorcycle of the present invention has: an air cleaner 1, a front 4, a pedal 5, a seat part 6, a wheel 7, and a transmission mechanism 8. The car body shell 9 and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com