Support frame for guaranteeing thickness of protective layer of floor slab and construction method thereof

A construction method and support frame technology, which are applied in the directions of structural elements, building components, building reinforcements, etc., can solve the problems that the gluten of the floor protection layer is difficult to be protected, the processing and installation are time-consuming and laborious, and the structure is complicated, and the guaranteed thickness can be achieved. , The effect of good construction quality, convenient processing and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

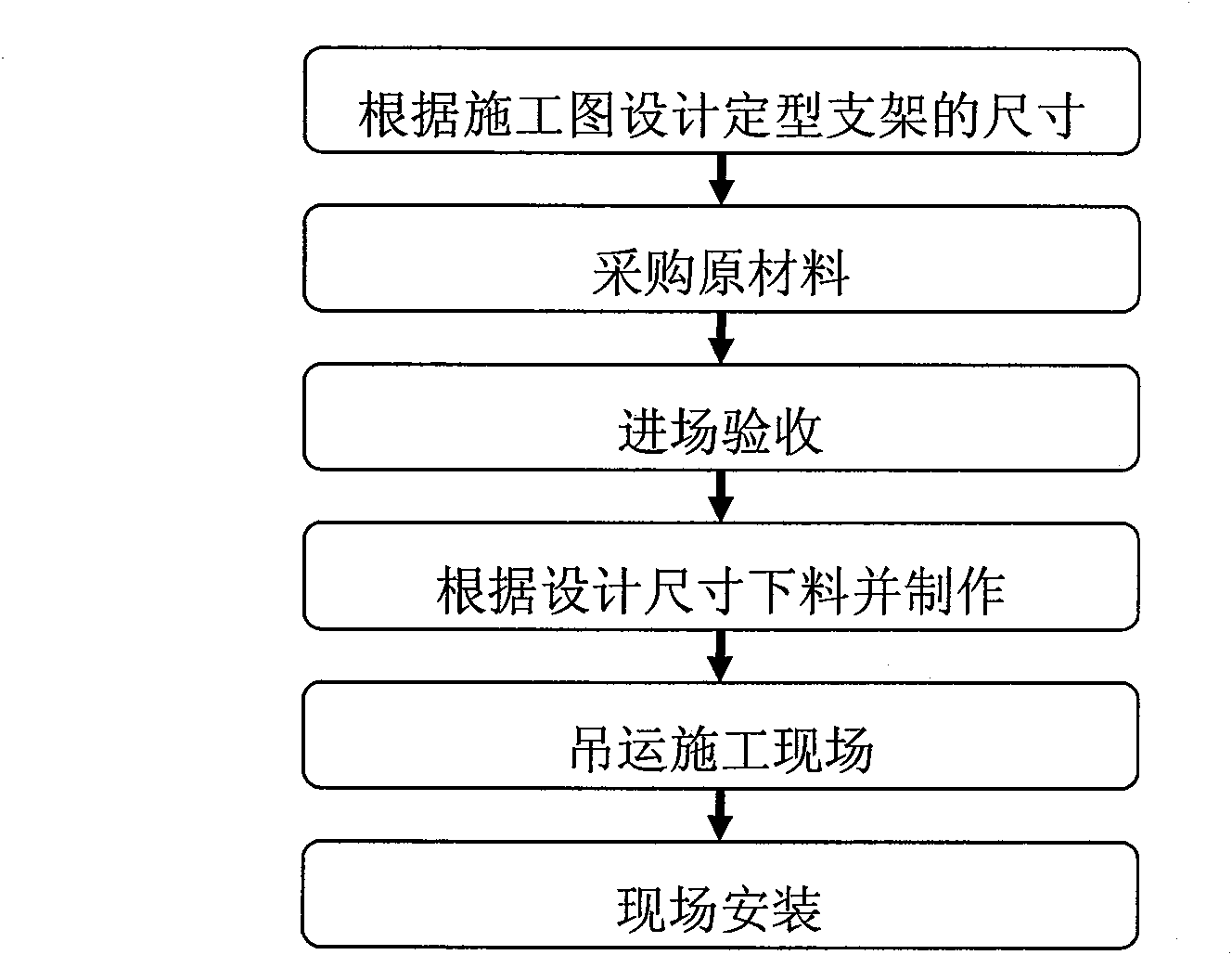

[0033] Further illustrate the present invention below in conjunction with accompanying drawing and embodiment:

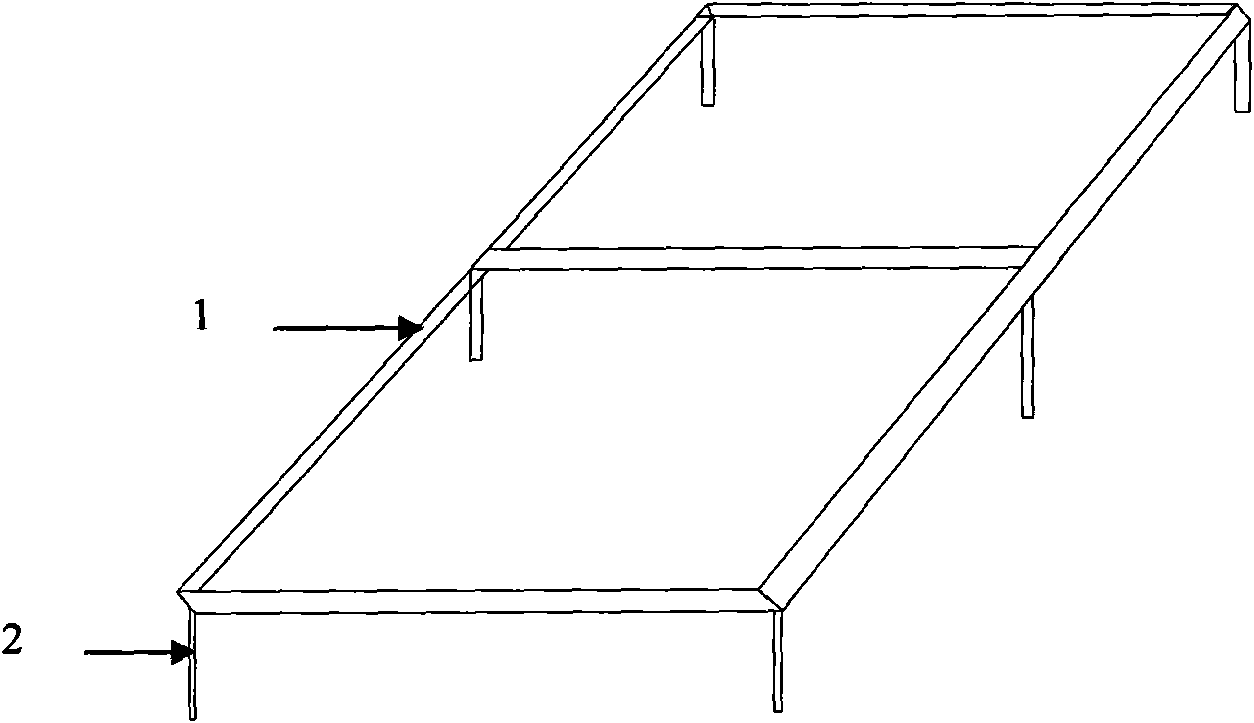

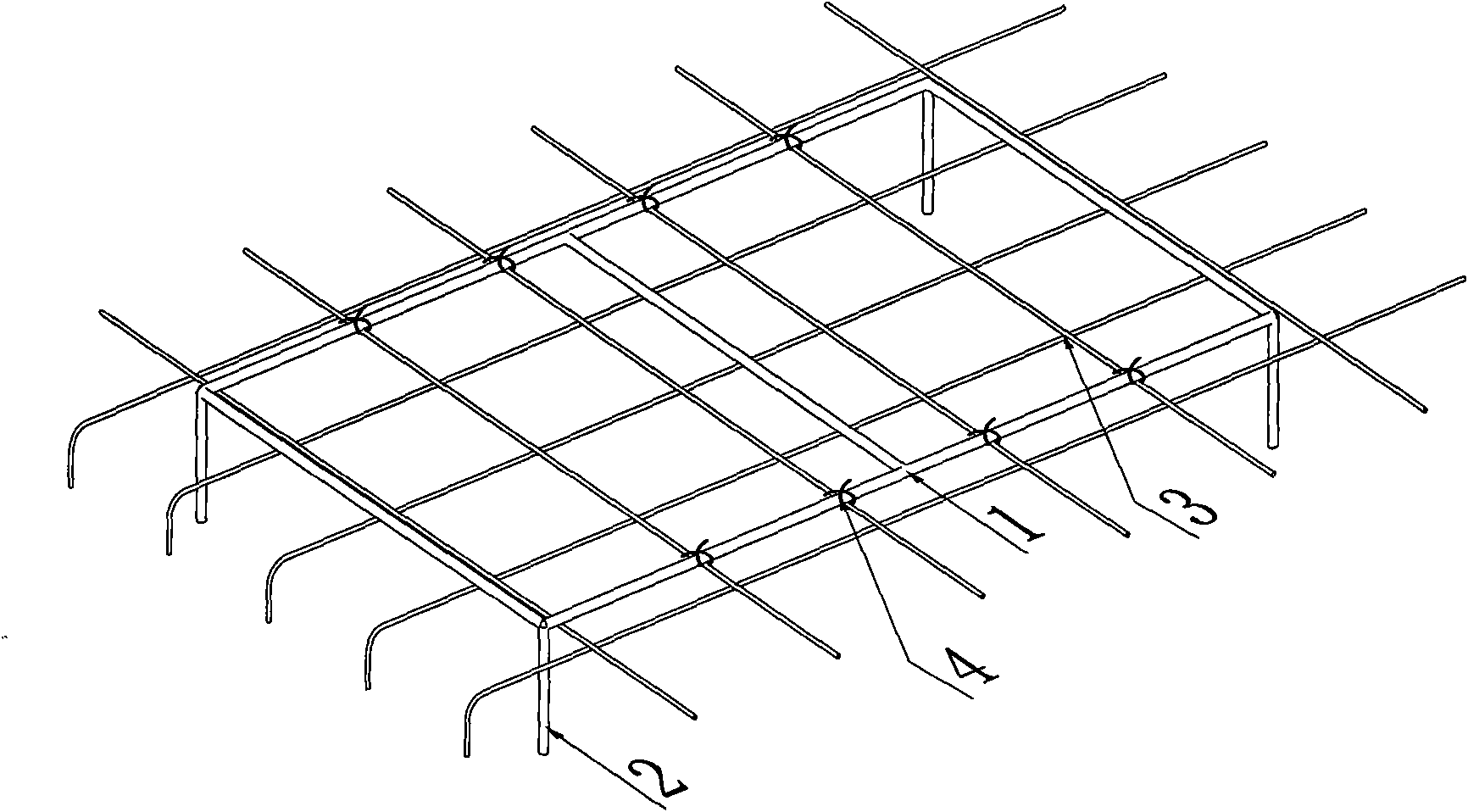

[0034] like figure 1 As shown, a support frame for protecting the protective layer of a concrete floor includes a bracket (1) welded by 5 galvanized steel pipes on a plane, and the bracket formed by the 5 galvanized steel pipes is a plane in the shape of "day". ”-shaped support (1), and 6 support feet (2) perpendicular to the plane where the support is located, the support feet (2) are respectively fixed at the connection points between the steel pipe and the steel pipe, wherein, The supporting feet are supported on the floor formwork at the bottom of the floor, and the length of the supporting feet is sufficient to ensure that the plane where the support is located is higher than the plane where the gluten of the floor is located. Therefore, when the staff binds the steel bars and pours concrete, it is the bracing frame of the present invention that is stepped on,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com