Capacitor type touch-control screen and process method thereof

A technology of capacitive touch and processing method, applied in the field of touch screen, can solve problems such as reducing the transmittance of the panel, and achieve the effect of improving the visual effect, uniform background color, and reducing the reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

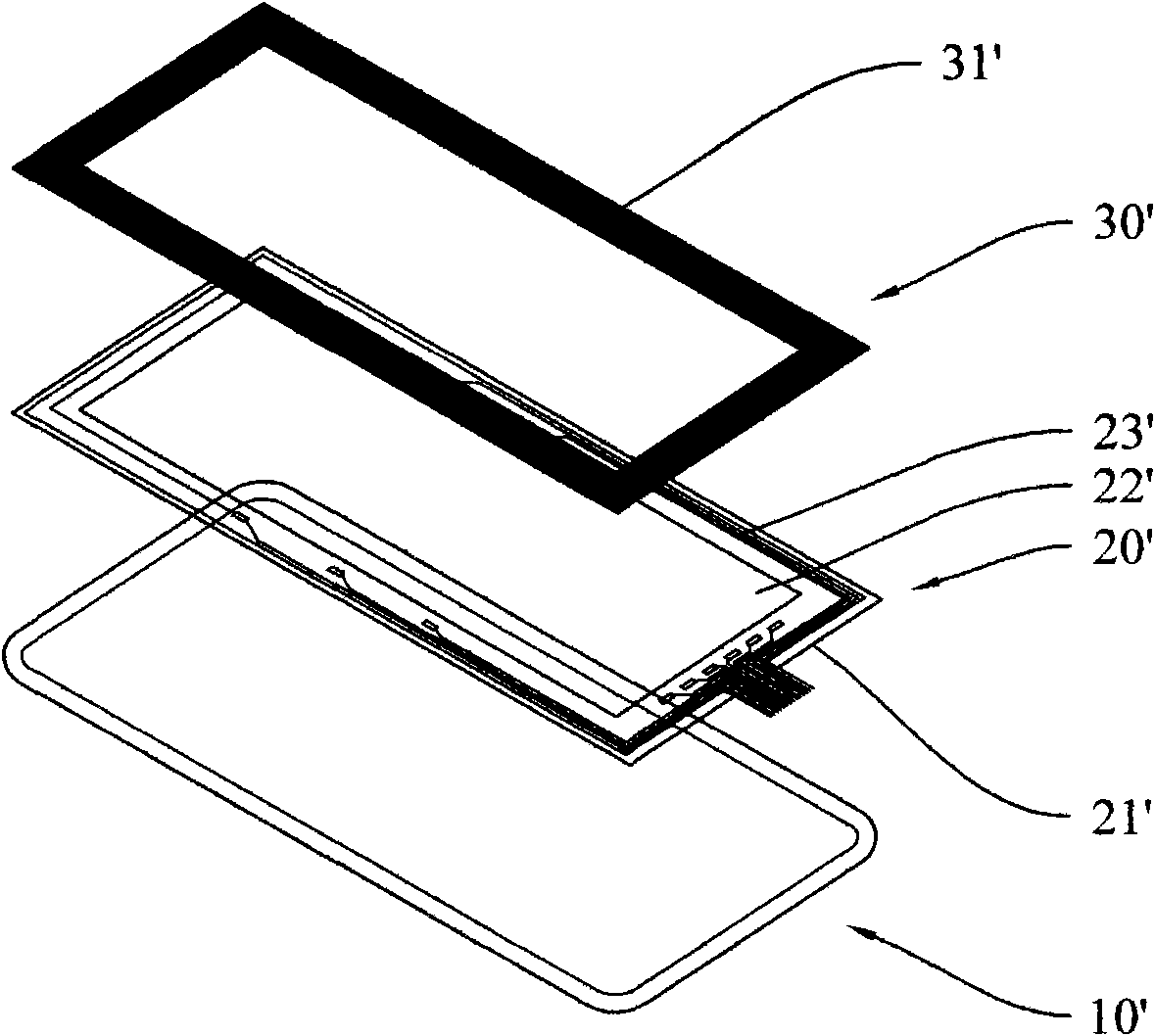

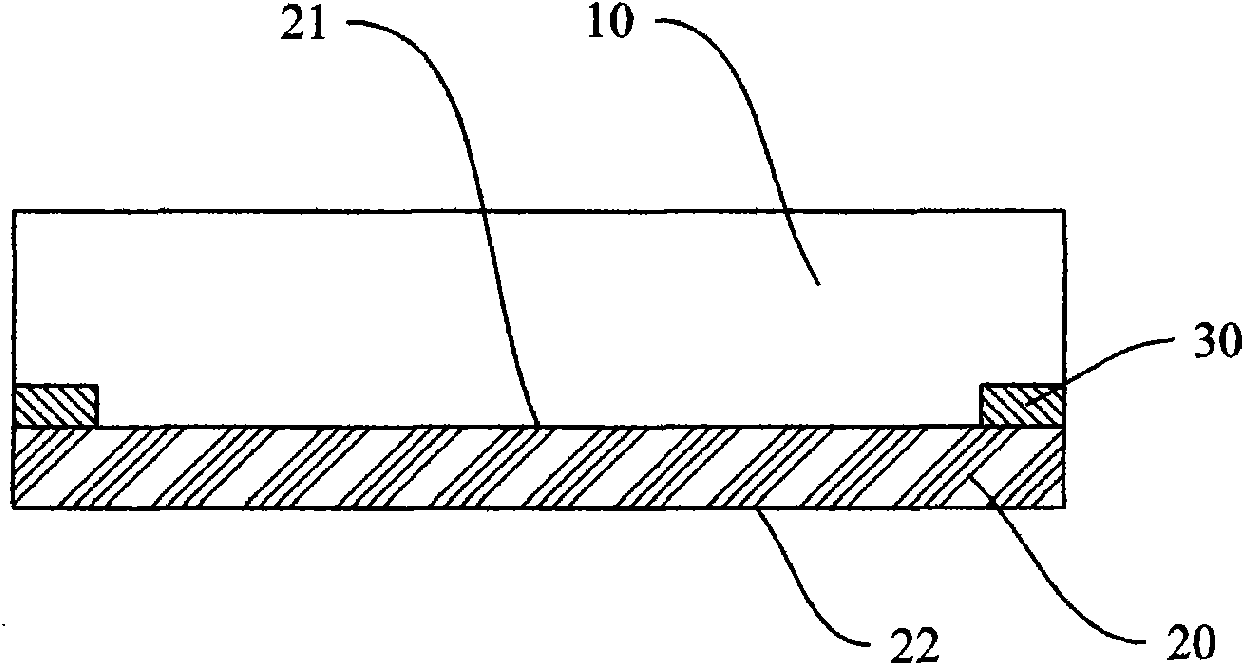

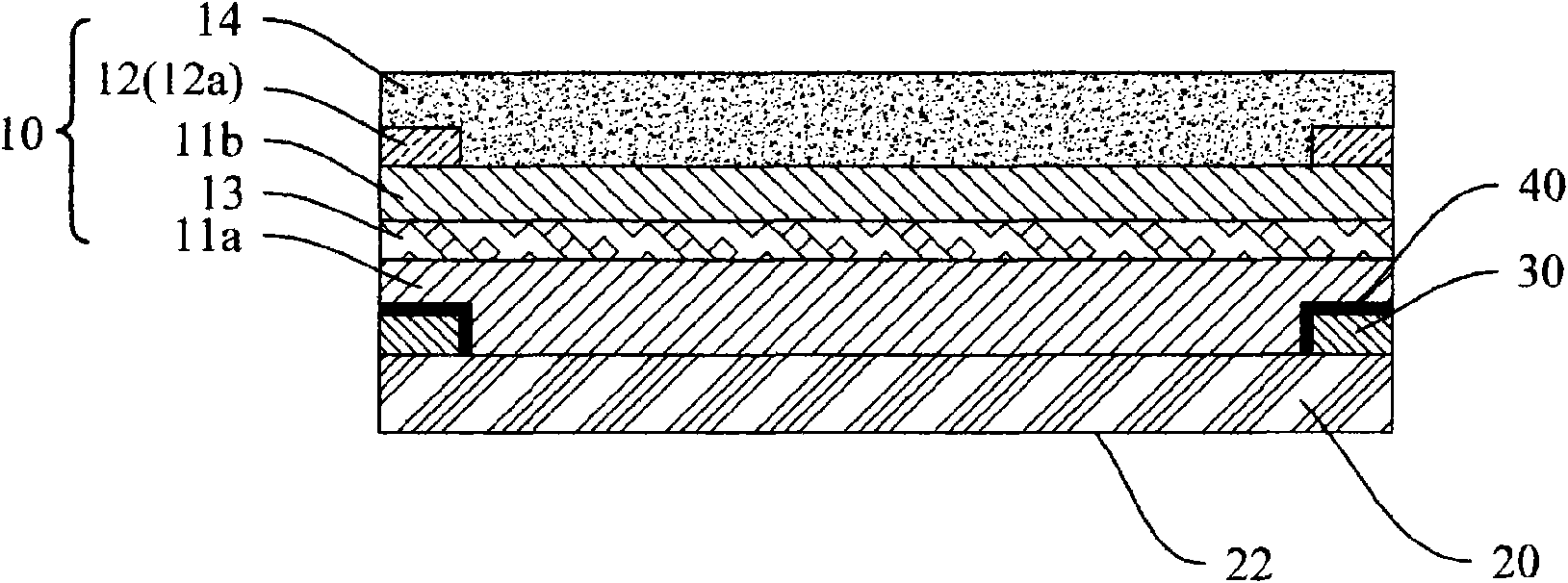

[0024] like figure 2 , 3 As shown in , 4, the capacitive touch screen shown in the present invention includes a transparent substrate 20, usually made of transparent glass. One side of the substrate 20 is a film surface 21 , and the other side is an air surface 22 . The film surface 21 side of the substrate is provided with a touch screen film layer 10 facing the backlight to sense the signal generated at the touch point and transmit it to the chip through the metal trace to calculate the position of the touch point. A mask layer 30 is provided between the substrate film surface 21 and the touch screen film layer 10 .

[0025] The touch screen film layer 10 generally includes an ITO layer 11 and a conductive layer 12 , and the metal wiring 12 a in the conductive layer 12 is used to electrically connect the ITO layer 11 to the chip. In order not to affect the visibility of the backlight source of the touch screen, the metal traces 12 a are usually distributed around the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com