Flexible rose work method and cutter for ring body surface used by magnetic-control sputtering ring piece

A technology of magnetron sputtering and knurling tools, which is applied in the direction of tools for lathes, manufacturing tools, accessories of tool holders, etc., can solve the problems of complex process, waste of materials, huge difference in knurling depth, etc., to ensure quality , the effect of saving raw materials and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

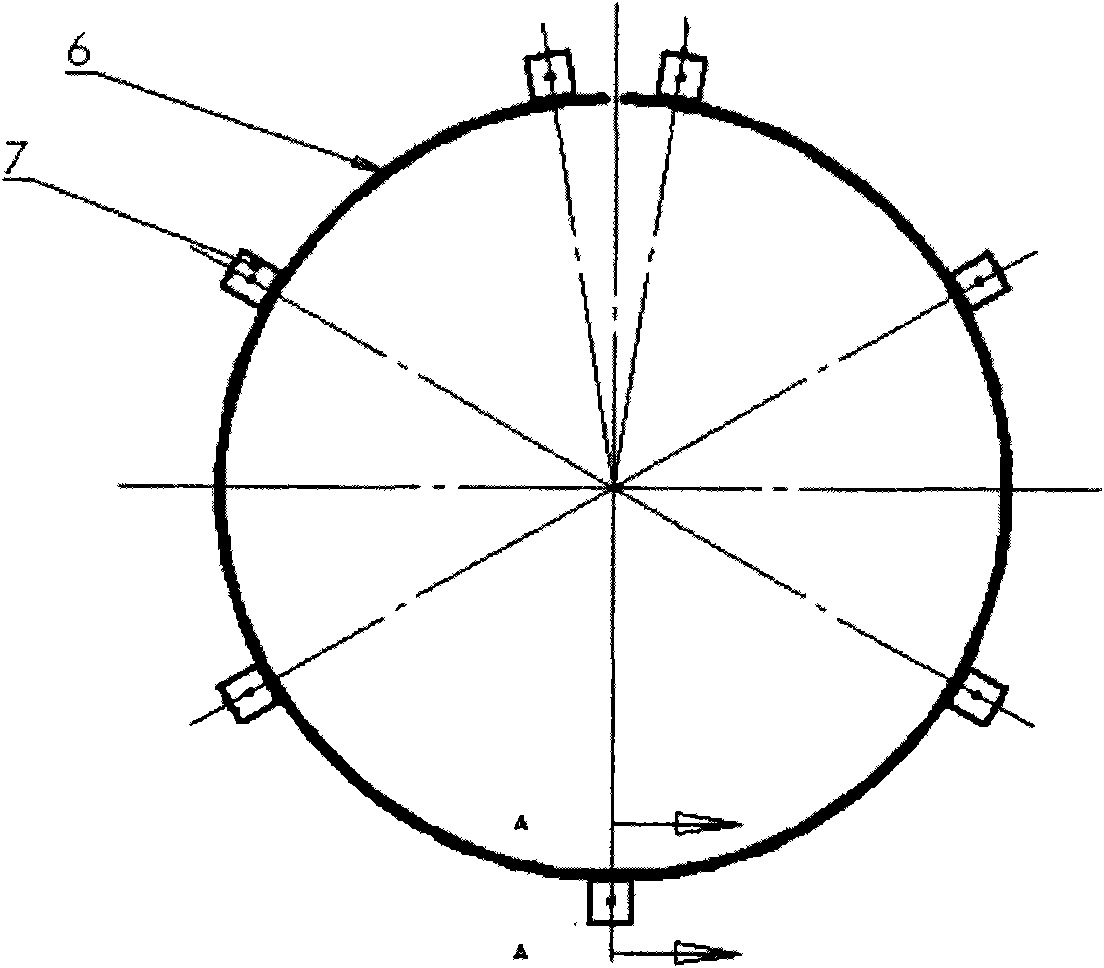

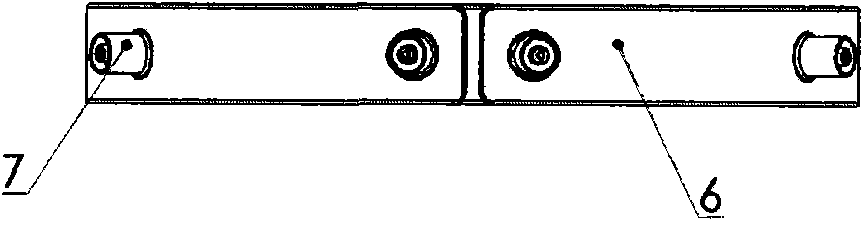

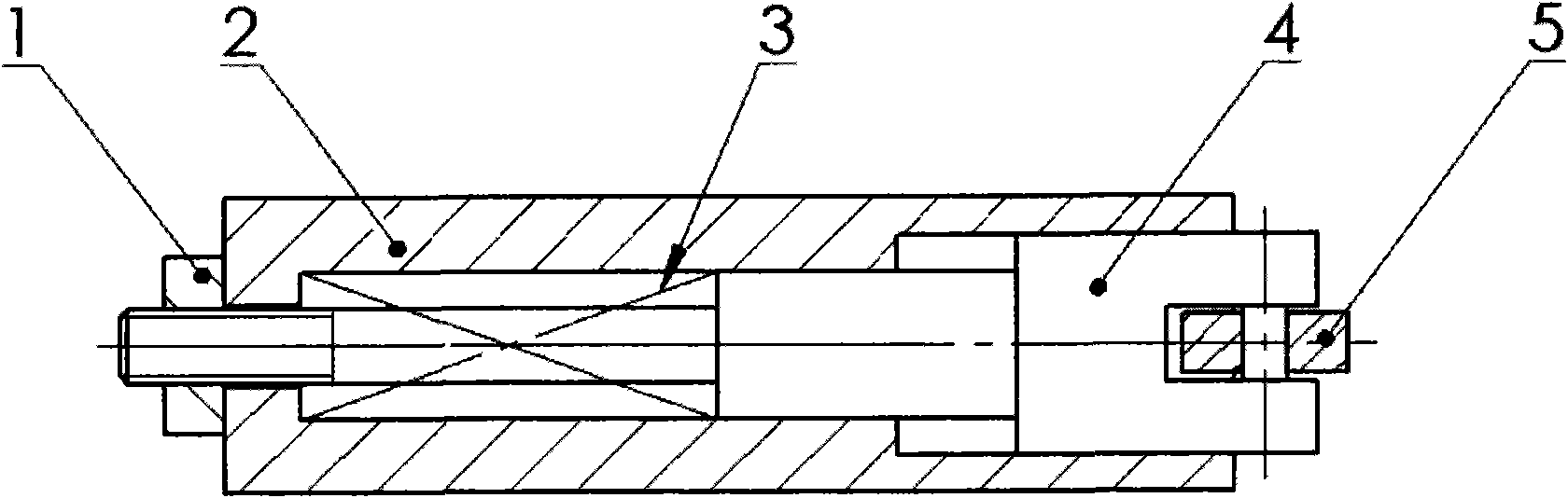

[0015] Such as figure 1 , figure 2 As shown, the processing object of the present invention is a magnetron sputtering ring, which consists of a ring body (6) and several convex knots (7) positioned at the outer edge of the ring. The problem to be solved by the present invention is that the inner and outer surfaces of the ring Rolled 80TPI convex diamond pattern. Tool structure of the present invention such as image 3 As shown, the structure of the knife handle (2) is similar to a sleeve, the structure of the knife rod (4) or (3) is similar to the piston rod located in the knife handle, and a spring or rubber-like elastic material is arranged between the two, and the knife rod One end of (4) or (3) is equipped with a roller (5), and the other end protrudes out of the handle and is equipped with a nut (1). The contact pressure between the roller and the workpiece can be adjusted by rotating the nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com