Water-based wood lacquer and preparation method thereof

A water-based wood paint and water-based acrylic technology, which is applied to biocide-containing paints, antifouling/underwater paints, coatings, etc., can solve problems such as hidden quality problems, large differences in refractive index, and decreased product transparency, and achieve enhanced Grinding performance, increased solid content, excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

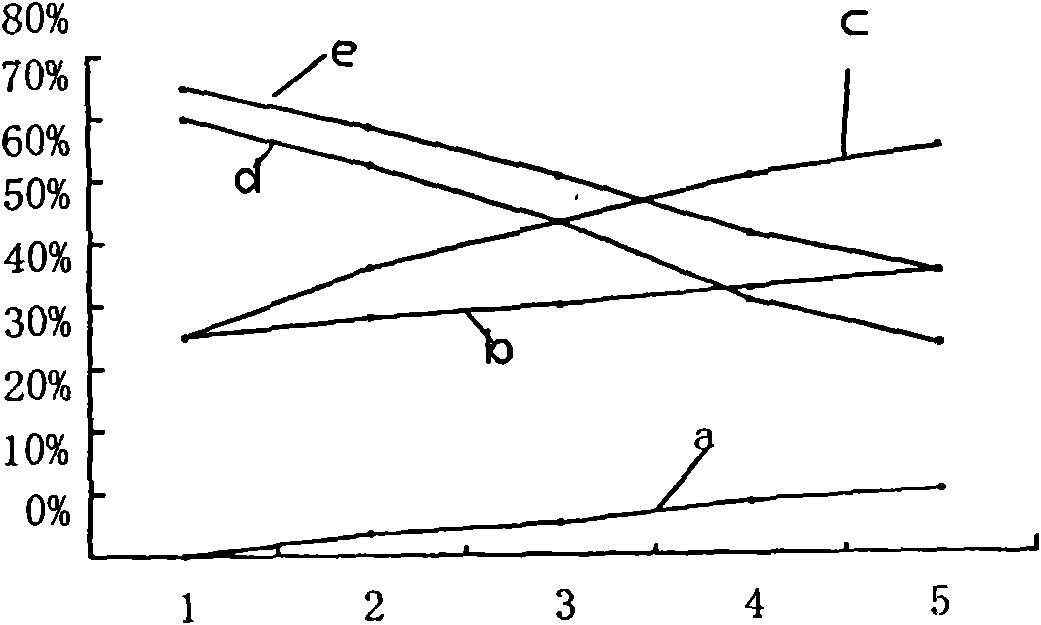

[0028] refer to figure 1 , a represents the amount of talcum powder (accounting for the total formula) %, b represents the solid content %, c represents the filling %, d represents the anti-whitening property % of the paint film, and e represents the transparency %.

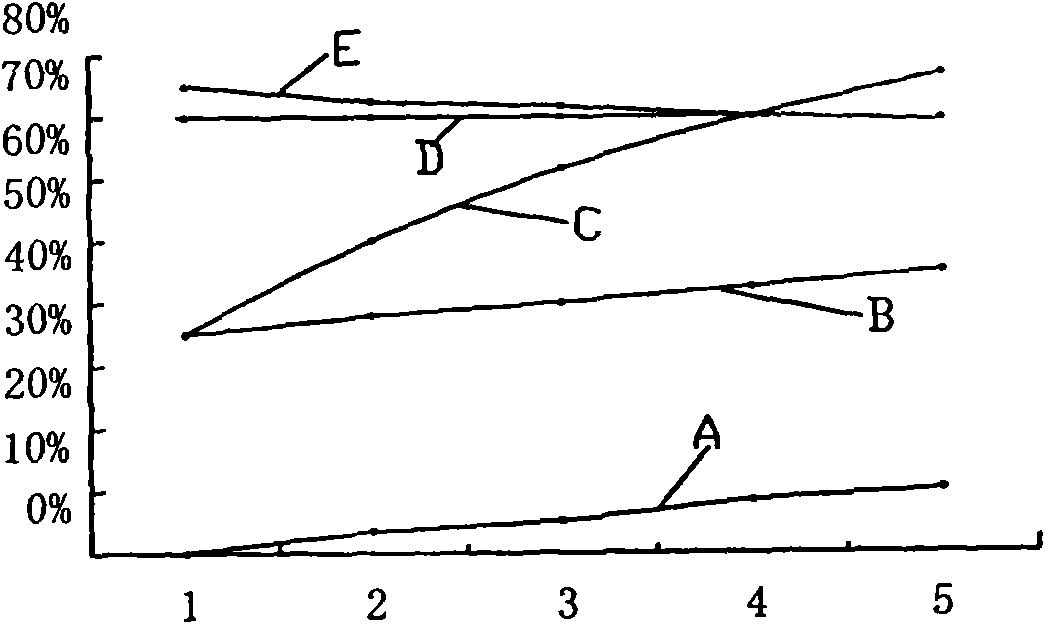

[0029] refer to figure 2 , A represents the amount of nano-inorganic silicon dioxide (accounting for the total amount of the formula) %, B represents the solid content %, C represents the filling %, D represents the whitening resistance % of the paint film, and E represents the transparency %.

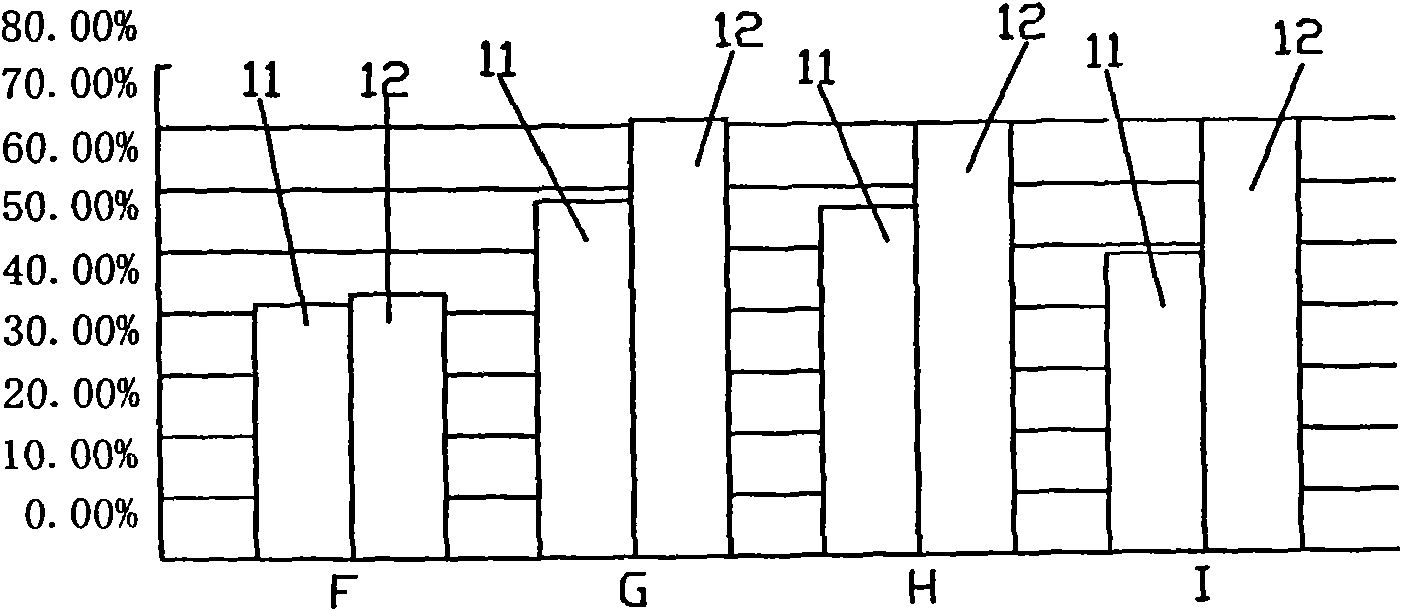

[0030] refer to image 3 , F represents solid content, G represents filling, H represents transparency, I represents anti-whitening property, 11 represents talcum powder, and 12 represents nano-inorganic silica.

[0031] In the present embodiment, the weight percentage of each material component is: water-based acrylic resin 81%, antifoam agent 0.1%, defoamer 0.2%, film-forming aid 6%, nano silicon dioxide slurry 11.5%...

specific Embodiment 2

[0078] The characteristics of this embodiment are: respectively weighing 78kg water-based acrylic resin, 0.1kg antifoaming agent, 0.2kg defoaming agent, 4kg film-forming aid, 13.5kg nano-silica slurry, 0.1kg antiseptic and bactericide and 4.2kg Water; Others are identical with specific embodiment 1.

[0079] The performance parameters of the water-based wood paint prepared in this example are: transparency %: 69, filling %: 71, whitening resistance % of the paint film: 69; meeting the performance index requirements of the product.

specific Embodiment 3

[0080] The characteristics of this embodiment are: respectively weighing 80kg water-based acrylic resin, 0.15kg antifoaming agent, 0.15kg defoaming agent, 5kg film-forming aid, 11.5kg nano-silica slurry, 0.1kg antiseptic and bactericide and 3.1kg Water; Others are identical with specific embodiment 1.

[0081] The performance parameters of the water-based wood paint prepared in this example are: transparency %: 71, filling %: 70, whitening resistance % of the paint film: 70; meeting the performance index requirements of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap