A new type of connecting member

A technology for connecting components and connecting brackets, applied in building structures, buildings, etc., can solve the problems of low reuse rate of prefabricated beams and columns, unfavorable industrialized mass production, and large loss of raw materials, so as to achieve industrialized mass production and reduce wet work. The effect of saving volume and construction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further introduced in conjunction with the accompanying drawings and specific embodiments.

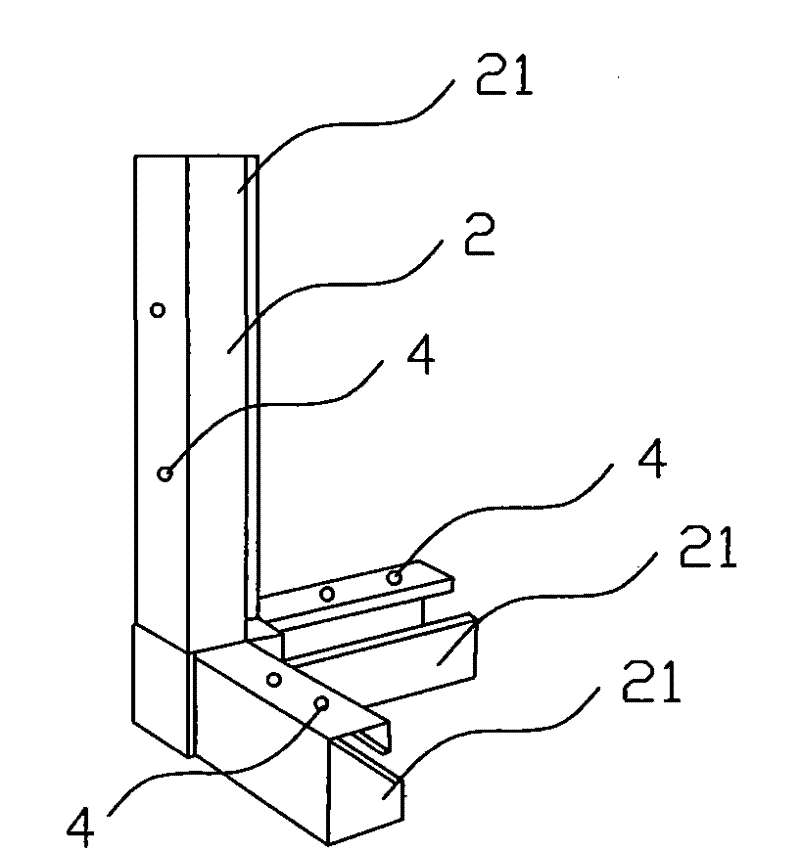

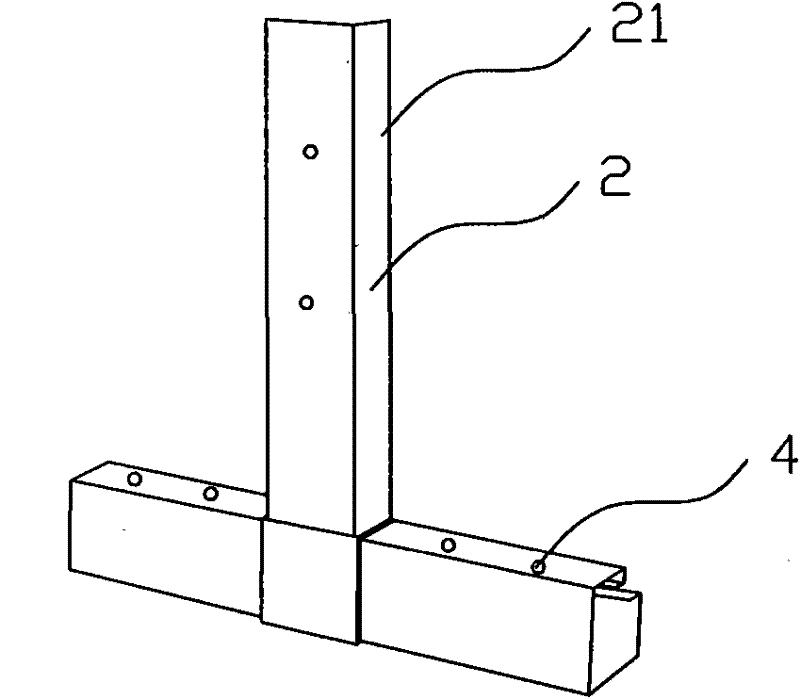

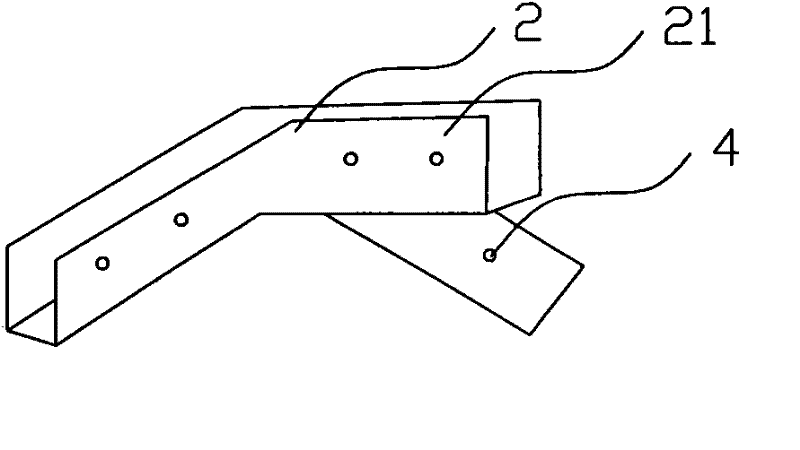

[0034] The present invention is a novel connecting component 1 for the structure of a prefabricated assembly room. The novel connecting component 1 includes a connecting bracket 2 , a connecting support 3 and a fixing part 4 .

[0035] The connecting bracket 2 has two or more sub-supports 21 made of metal, and the plurality of sub-supports 21 form a certain angle with each other to form a three-dimensional polar coordinate structure, a planar coordinate structure, etc., and the angles can also be varied. The sub-supports 2 are respectively hollow and solid, and the hollow longitudinal section is a concave, C-shaped, U-shaped, L-shaped, [-shaped or spoon-shaped groove structure with yin and yang cooperation.

[0036] The connecting support body 3 is the prefabricated beam and the prefabricated station column of the prefabricated assembly room, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com