Method for building factory-style light integral quakeproof house and quakeproof house component

A factory-like, earthquake-proof house technology, applied in the direction of earthquake-proof, building components, building types, etc., can solve the problems of high manual labor intensity, poor earthquake-proof effect, and failure to build

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

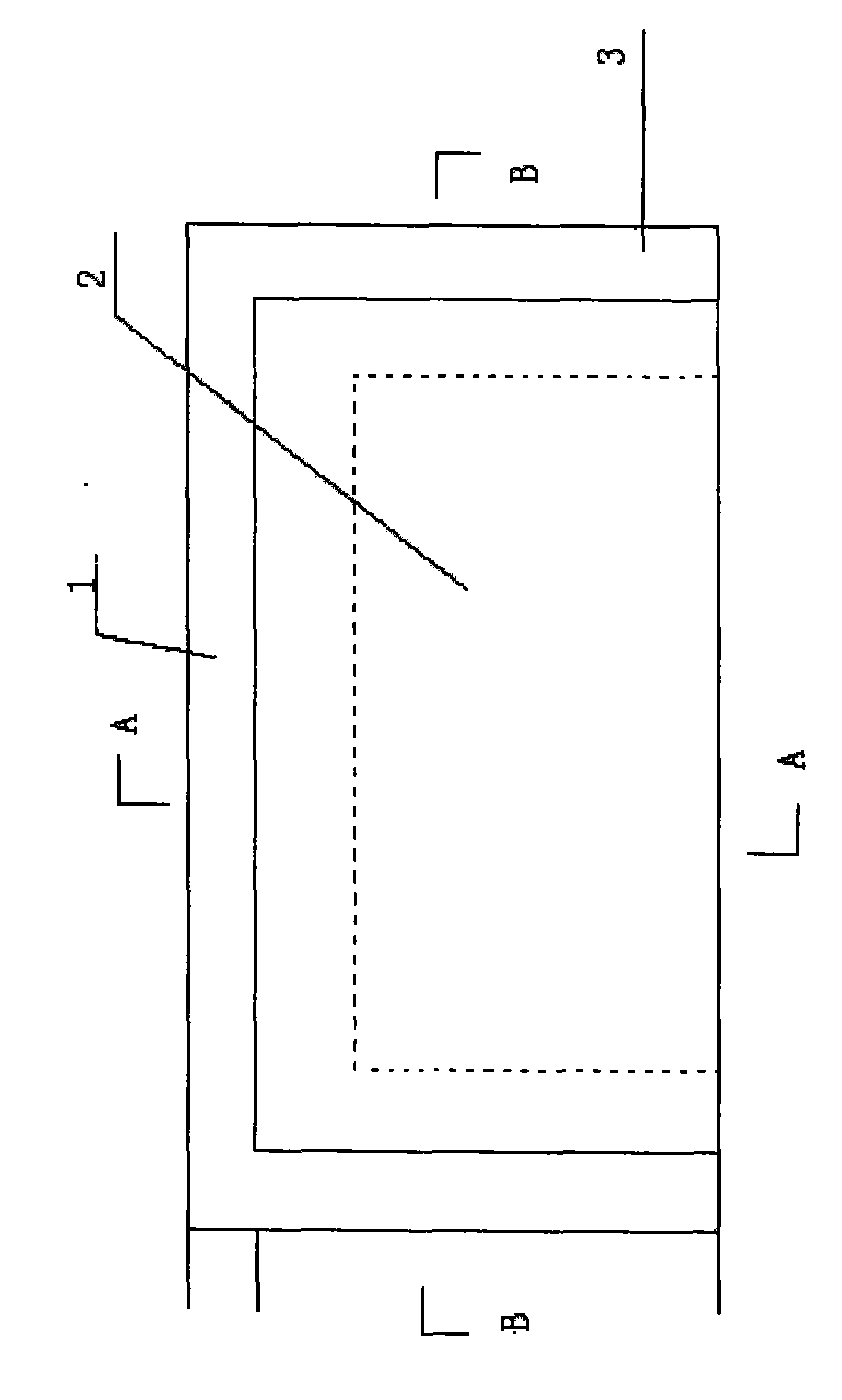

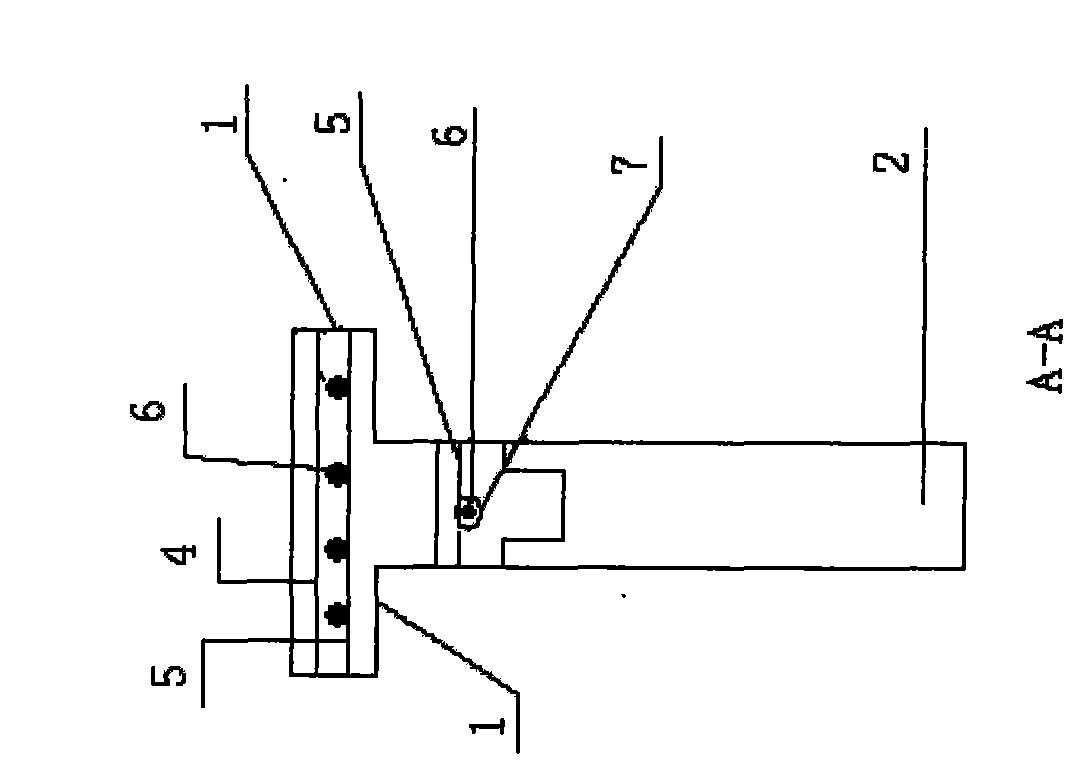

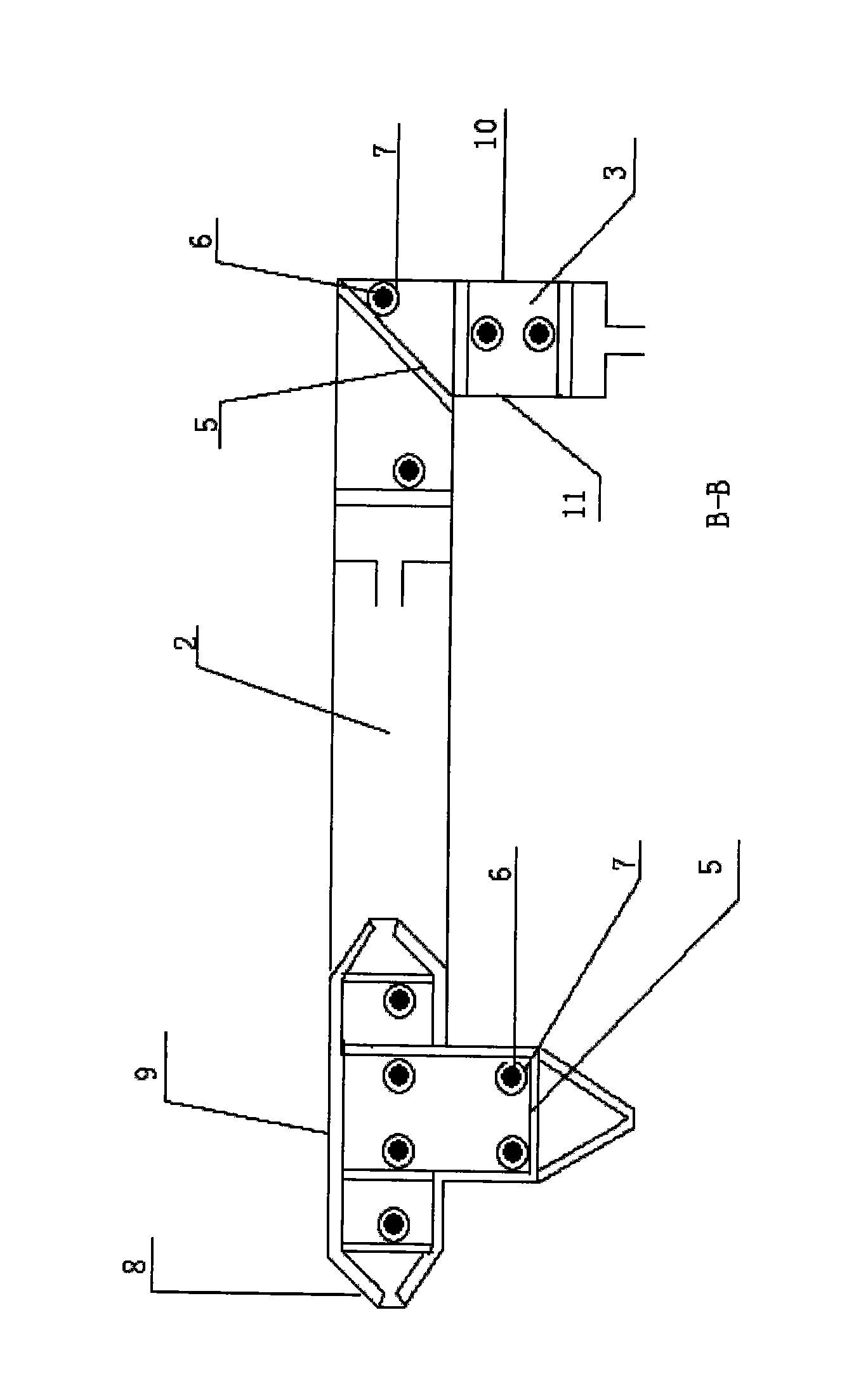

[0021] The structure of columns, ring beams and walls is as follows Figure 1 to Figure 3 shown. The template shape is the same as the existing template, Figure 1 to Figure 3 The middle is a rectangular column template, including two rectangular column templates 1, 10, 11 and a straight column template 9. Right-angled column templates 1, 10, 11 and straight column templates 9 are made by pressing plant shells, hearts, leaves, rods or roots, etc., with smooth surfaces. Between the rectangular column formwork 1, 10, 11 and the rectangular column formwork 1, 10, 11, between the rectangular column formwork 1, 10, 11 and the straight column formwork 9, an inner pull-type fixing rod 5 is arranged, and the inner pull The type fixing bar 5 is provided with a steel bar fixing ring 7, which is used to be suitably fixed on the steel bar 6, which changes the existing external fixing method, and eliminates the operation of installing, fixing and dismounting. 2. The inner wall and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com