Top-down decreasing-formwork formwork system and construction method

A construction method and formwork technology, which is applied in formwork/formwork/work frame, artificial island, water conservancy projects, etc., can solve problems such as poor construction continuity, unfavorable environmental control, and large over-excavation depth, so as to speed up and reduce over-excavation. The depth of digging and the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

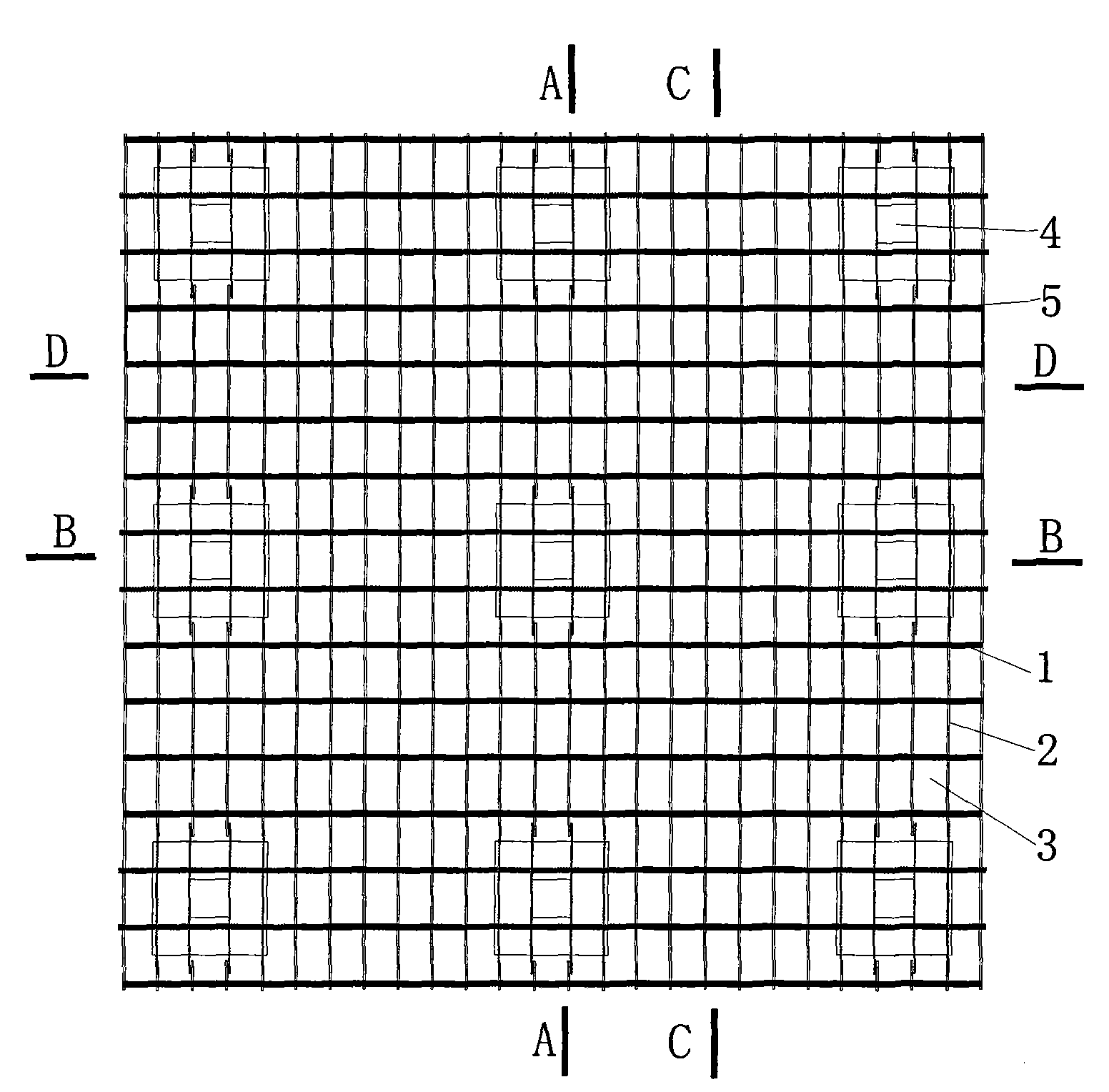

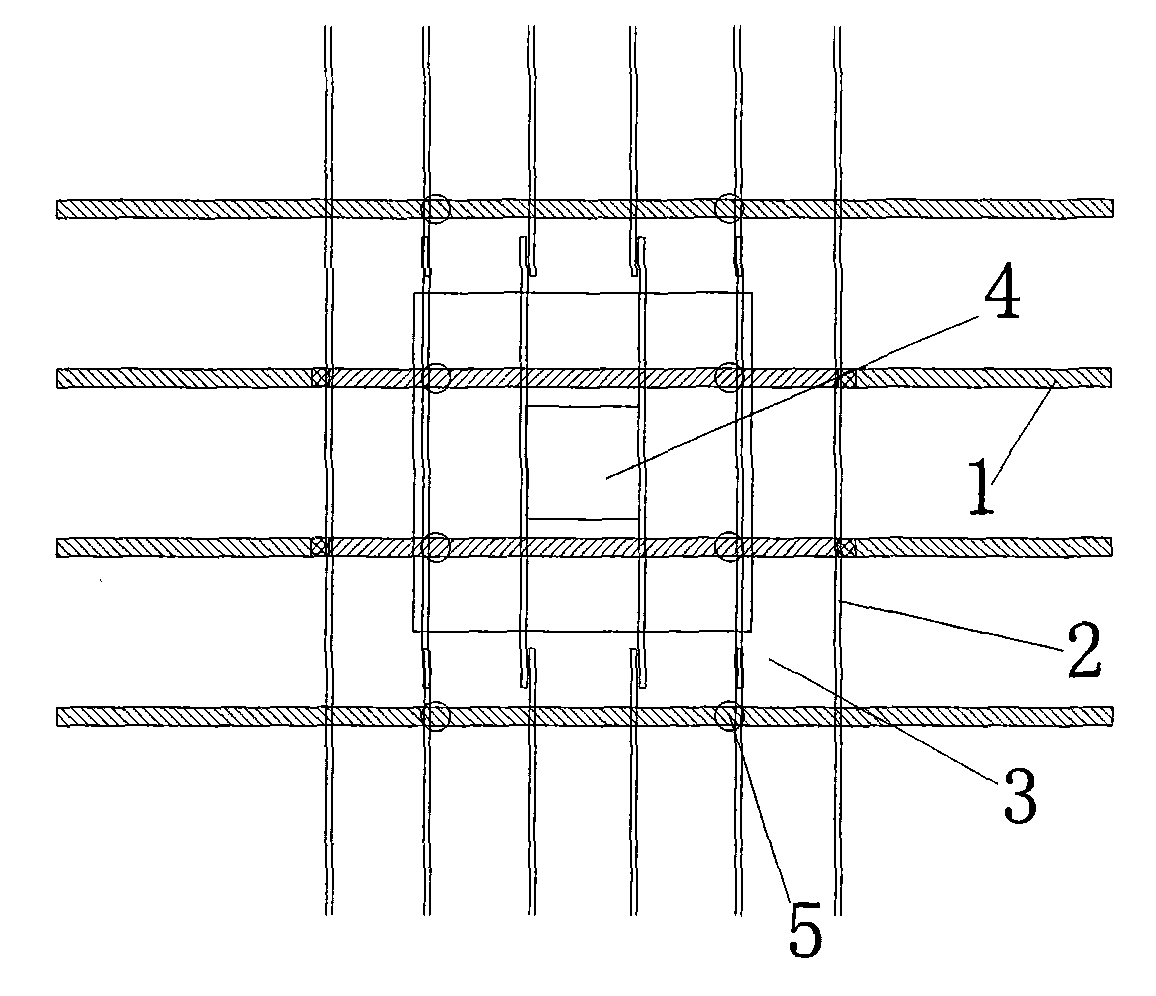

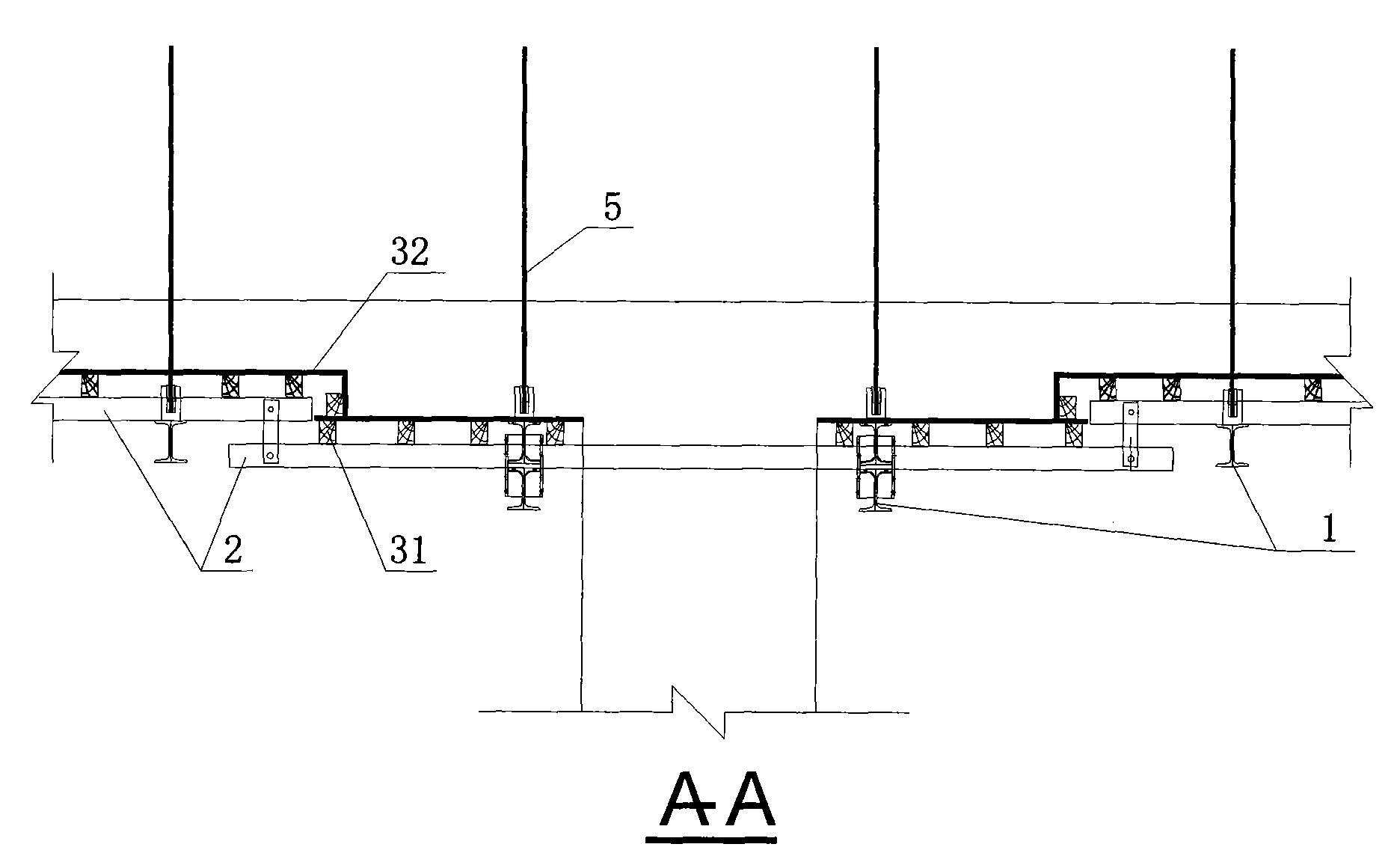

[0023] Such as Figure 1~6 As shown, the reverse formwork formwork system of the present invention includes a main beam 1, a secondary beam 2 and a formwork 3 fixed on the secondary beam. The formwork is reserved at the position of the structural column with a column hole 4 for the structural column to pass through. , also includes a boom 5 and a manual hoist 6, the boom 5 is arranged vertically on the entire drop formwork system in a matrix structure, the lower end of the boom 5 is fixedly connected to the main beam 1, and the length of the boom 5 is longer than that of the basement According to the floor height of the structure, the lifting nut 51 is arranged on the suspender; the lifting point 61 of the manual hoist is arranged at the upper end of the suspender 5 around the column cap.

[0024] The formwork system is divided into a formwork structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com