Corrugated pipe joint

A bellows, main body technology, applied in the direction of pipes/pipe joints/pipe fittings, hose connection devices, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

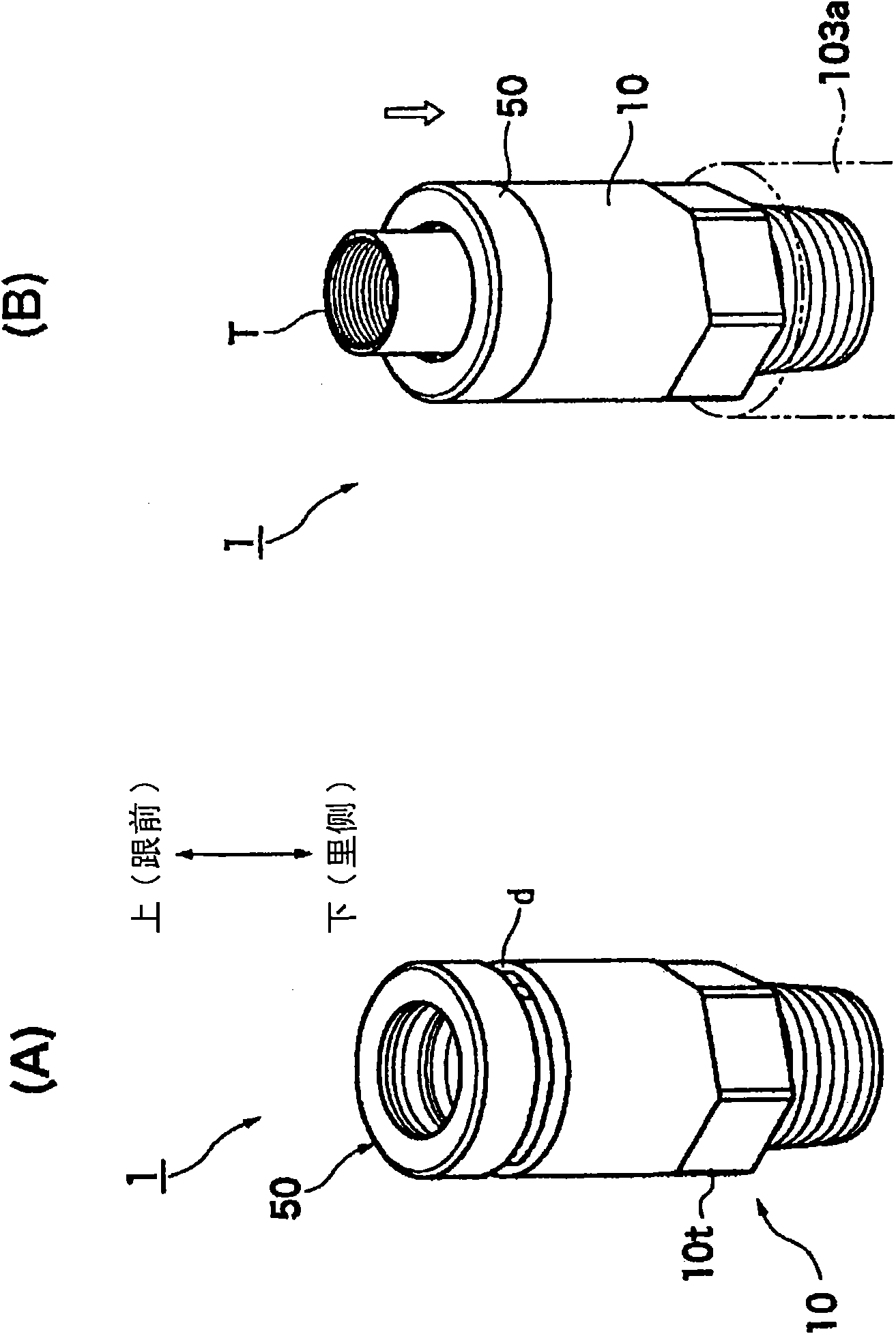

[0172] figure 1 It is an external perspective view explaining the outline of the bellows joint according to the first embodiment of the present invention, figure 1 (A) is a diagram showing the initial state of the joint, figure 1 (B) shows the final state of the joint (construction completion state of bellows insertion).

[0173] In addition, in the following description, unless otherwise specified, "up and down" means figure 1 In the direction indicated by the middle arrow. "Front" indicates the upper side in the figure (root side of the corrugated tube), and "rear side" indicates the lower side in the figure (front side of the corrugated tube).

[0174] First, the outline of the bellows joint 1 will be described.

[0175] The bellows fitting 1, such as figure 1 (A) shows a cylindrical joint main body 10 in which various components (not shown in the figure) are arranged inside (details will be described later), and a retainer press cylinder 50 provided so as to be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com