Oil tank for oil immersion type transformer

An oil-immersed transformer and oil tank technology, applied in the field of transformers, can solve problems affecting the heat dissipation performance of the oil tank, unsatisfactory cost performance, and difficult fixed support, etc., and achieve the effects of improving noise pollution, simple structure, and remarkable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

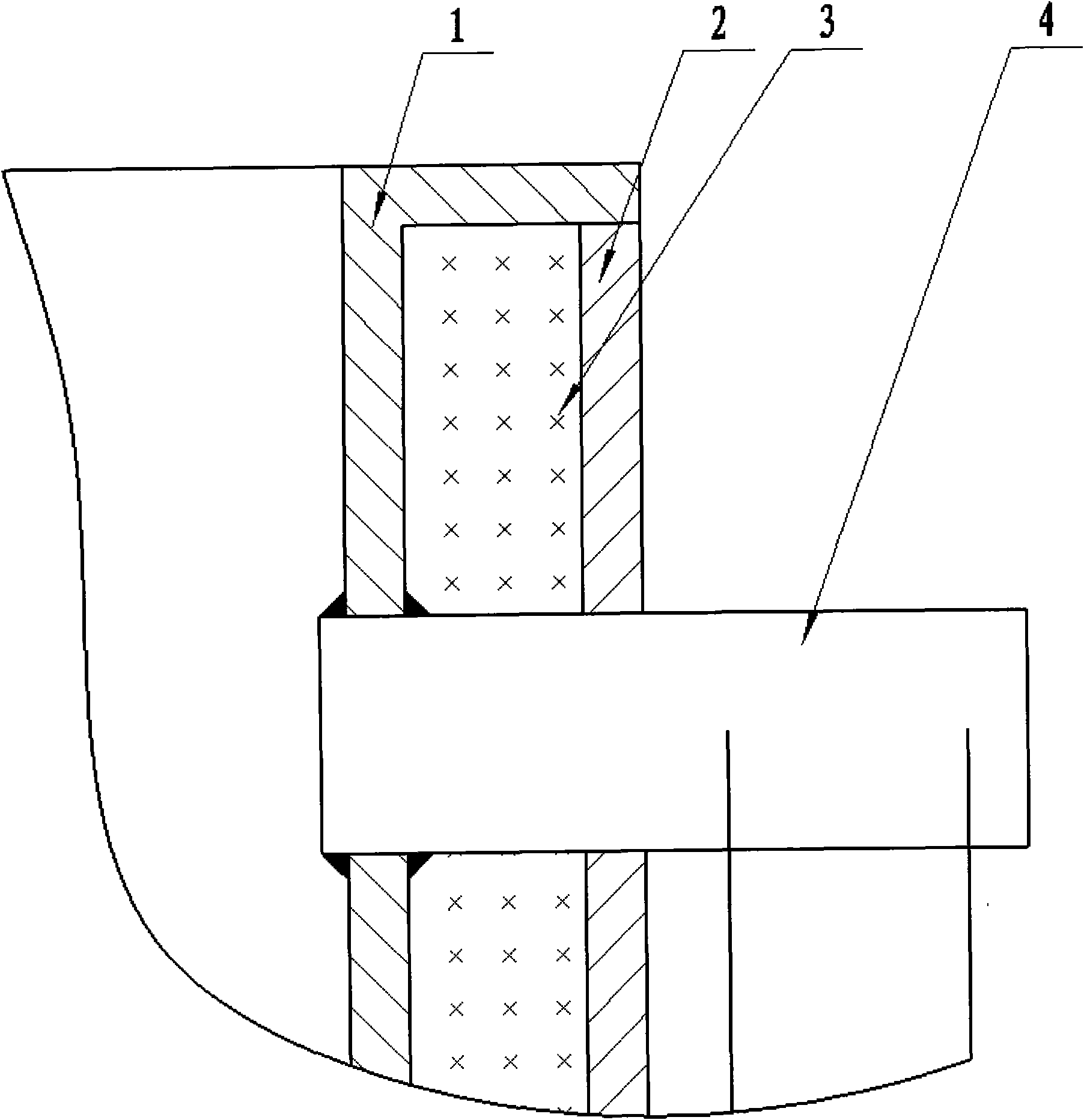

[0010] Such as figure 1 As shown, the present invention is an oil-immersed transformer oil tank, which is used to reduce the noise of an oil-immersed transformer, comprising an oil tank body 1 and a layer of tank wall structure 2 arranged outside the oil tank body 1, and the tank wall structure 2 The fuel tank body 1 is provided with preset air gaps, and the air gaps are lined with flame-retardant and sound-absorbing materials 3 .

[0011] In the present invention, the original sealing structure of the oil-immersed transformer is borne by the oil tank body 1, and the tank wall structure 2 and the oil tank body 1 are connected and fixed to the radiator tube 4 of the oil-immersed transformer by electric welding.

[0012] When the transformer noise is transmitted to the double-layer oil tank structure, the sound waves generated through the air layer and the damping effect of the sound-absorbing material can be greatly weakened, thereby reducing the noise of the transformer. Prac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com