Catalyst for synthesizing ammonia through activated-carbon-loading ruthenium, and preparation method thereof

The technology of activated carbon and catalyst is applied in the field of preparation of activated carbon-supported ruthenium ammonia synthesis catalyst, which can solve the problems of high catalyst cost and hinder the popularization and use of catalyst, and achieve the effect of low content of precious metal ruthenium and high degree of dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Take 500 grams of BET specific surface area is 1250m 2 / g short cylindrical coconut shell charcoal with a length of about 3-15mm, washed with water at room temperature and dried at 80-120°C to remove water, then placed in a high-temperature furnace, and treated at 1800-1900°C for 2 hours under the protection of an inert gas. After the temperature was lowered to room temperature, it was taken out and placed in a hole reaming furnace, fed with oxygen, CO 2 The mixed gas composed of nitrogen, nitrogen and water vapor was treated at 460°C for 16 hours and then cooled to room temperature for use. The resulting shaped carbon has a compressive strength ≥ 90N / cm (cylindrical), a wear rate ≤ 0.4%, and a BET specific surface area of 1000m 2 / g.

[0013] Get 100g of the above-mentioned activated carbon carrier, and use Ba(NO 3 ) 2 , Mg(NO 3 ) 2 、La 2 (NO 3 ) 3 aqueous solution (or three salt mixture aqueous solutions at the same time) for impregnation. Based on the wei...

Embodiment 2

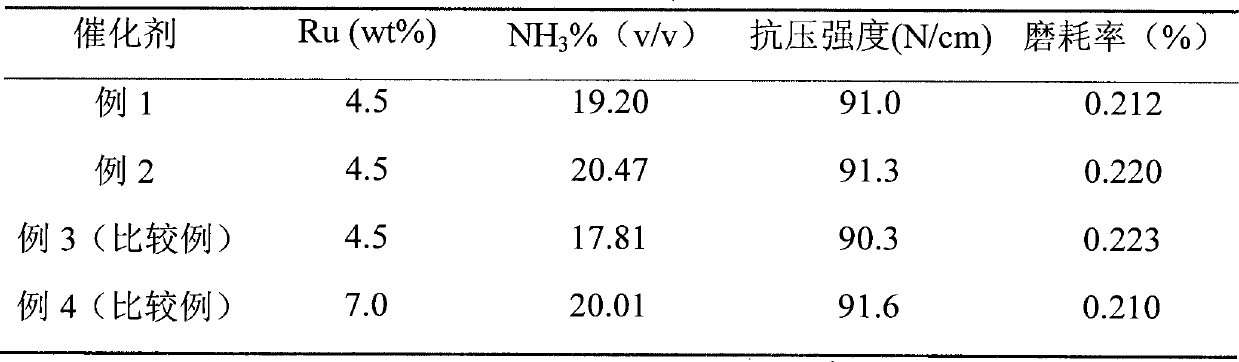

[0018] Example 1 was repeated except that ethanol was used as the solvent for the KOH when impregnating the KOH. Based on the weight of the activated carbon carrier, the composition of the catalyst is: Ru: 4.5%, Ba: 4%, Mg: 1.4%, La: 0.1%, K: 17%. The determination method and conditions of the physical and chemical parameters of the catalyst are the same as in Example 1, and the mechanical strength and ammonia synthesis activity of the catalyst are shown in Table 1.

Embodiment 3

[0019] Embodiment 3 (comparative example)

[0020] Repeat embodiment 1, just auxiliary agent composition does not contain magnesium and rare earth. Based on the weight of the active carbon carrier, the composition of the catalyst is: Ru: 4.5%, Ba: 4%, K: 17%. The determination method and conditions of the physical and chemical parameters of the catalyst are the same as in Example 1, and the mechanical strength and ammonia synthesis activity of the catalyst are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com