Grooving machine for metal circular saw blades

A circular saw blade and slotting machine technology, which is applied in metal sawing equipment, metal processing equipment, tool manufacturing of sawing machine devices, etc., can solve the problems of poor safety, lack of positioning accuracy, complicated operation, etc. The effect of safe processing operation and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

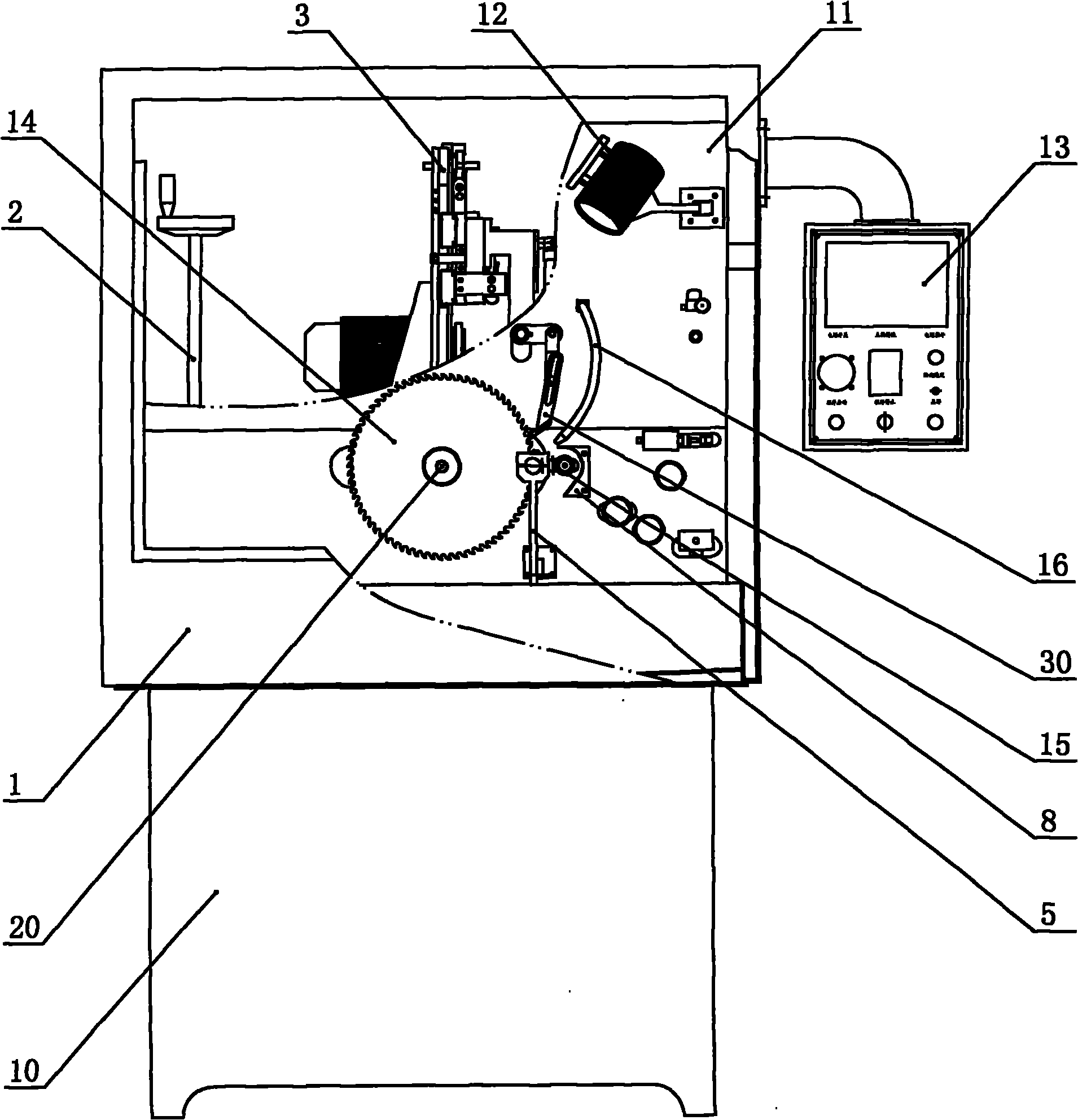

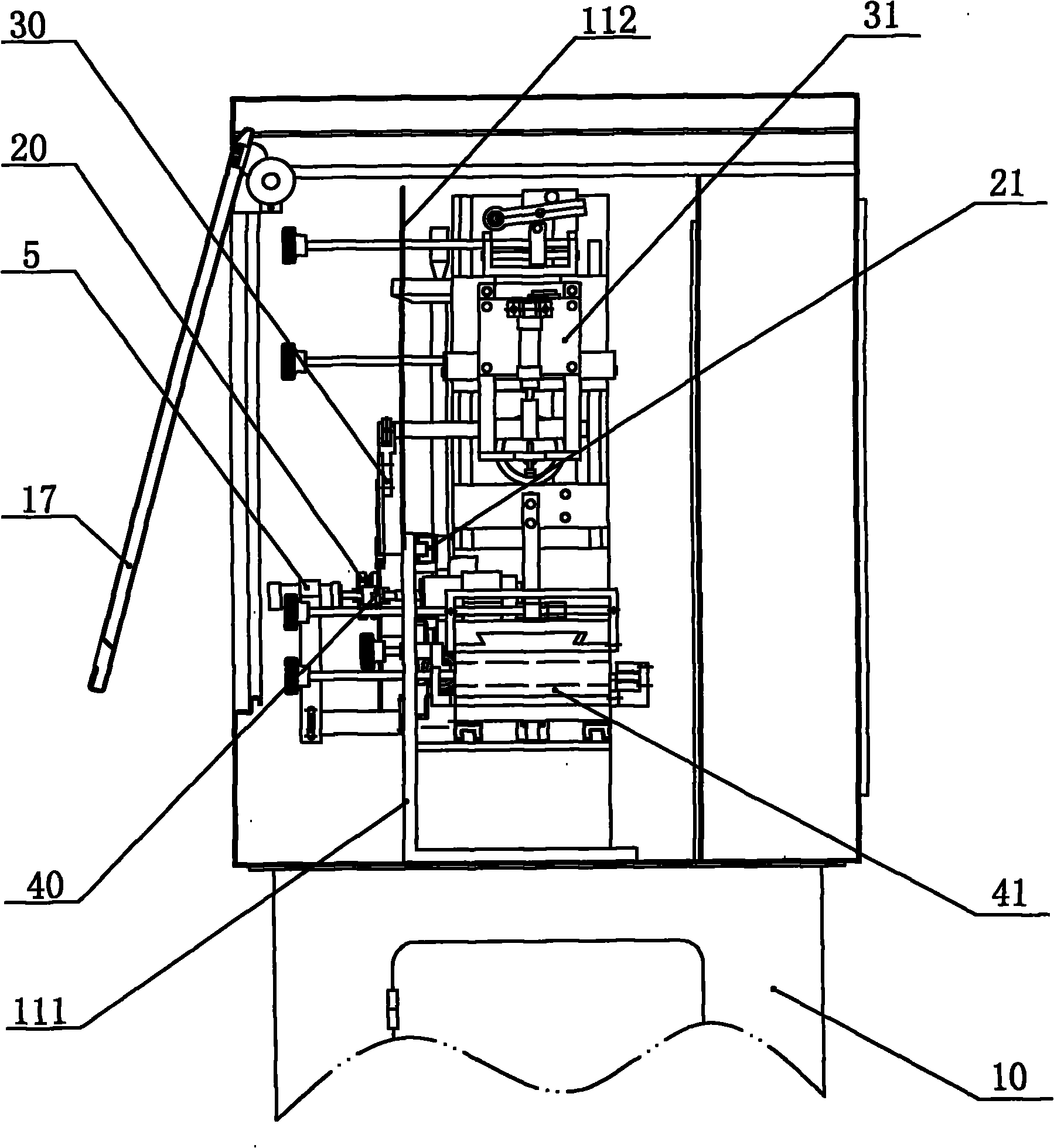

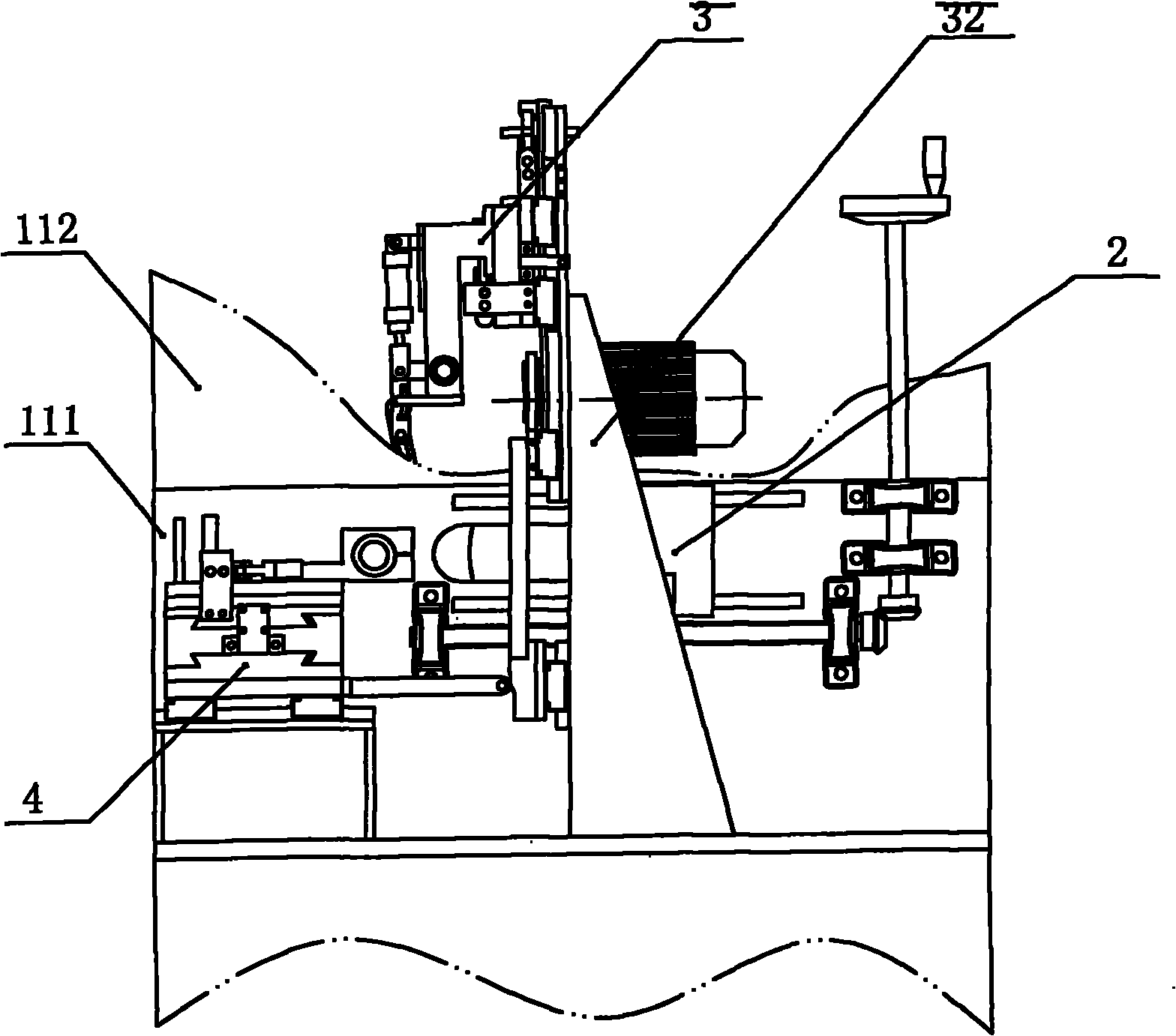

[0064] Such as figure 1 , figure 2 and image 3 As shown, a metal circular saw blade slotting machine includes a frame 1, a saw blade positioning device 2 fixed on the frame 1, a saw blade stepping drive device 3 and a slotting cutter drive device 4; Wherein the frame 1 includes a base frame 10 , a central controller 13 is arranged on the right side of the frame 1 , and a screen board 11 is arranged in the frame 1 . A working lighting lamp 12 and a delivery pipe 16 for cooling gas that lowers the grinding temperature are also arranged on the screen plate 11 .

[0065] Such as figure 2 As shown, the screen panel 11 includes a lower screen panel 111 and an upper screen panel 112 . The lower screen plate 111 and the upper screen plate 112 are arranged in sections, wherein the thickness and strength of the lower screen plate 111 are greater than that of the upper screen plate 112, and other main components are carried by the lower screen plate 111, while The upper screen pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com