Method for producing medical rubber bottle cork made of dual composite material

A composite molding and production method technology, applied in applications, household components, household appliances, etc., can solve the problems of high production cost of bottle stoppers and high requirements for safety indicators, and achieve the effect of reducing production costs and ensuring safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

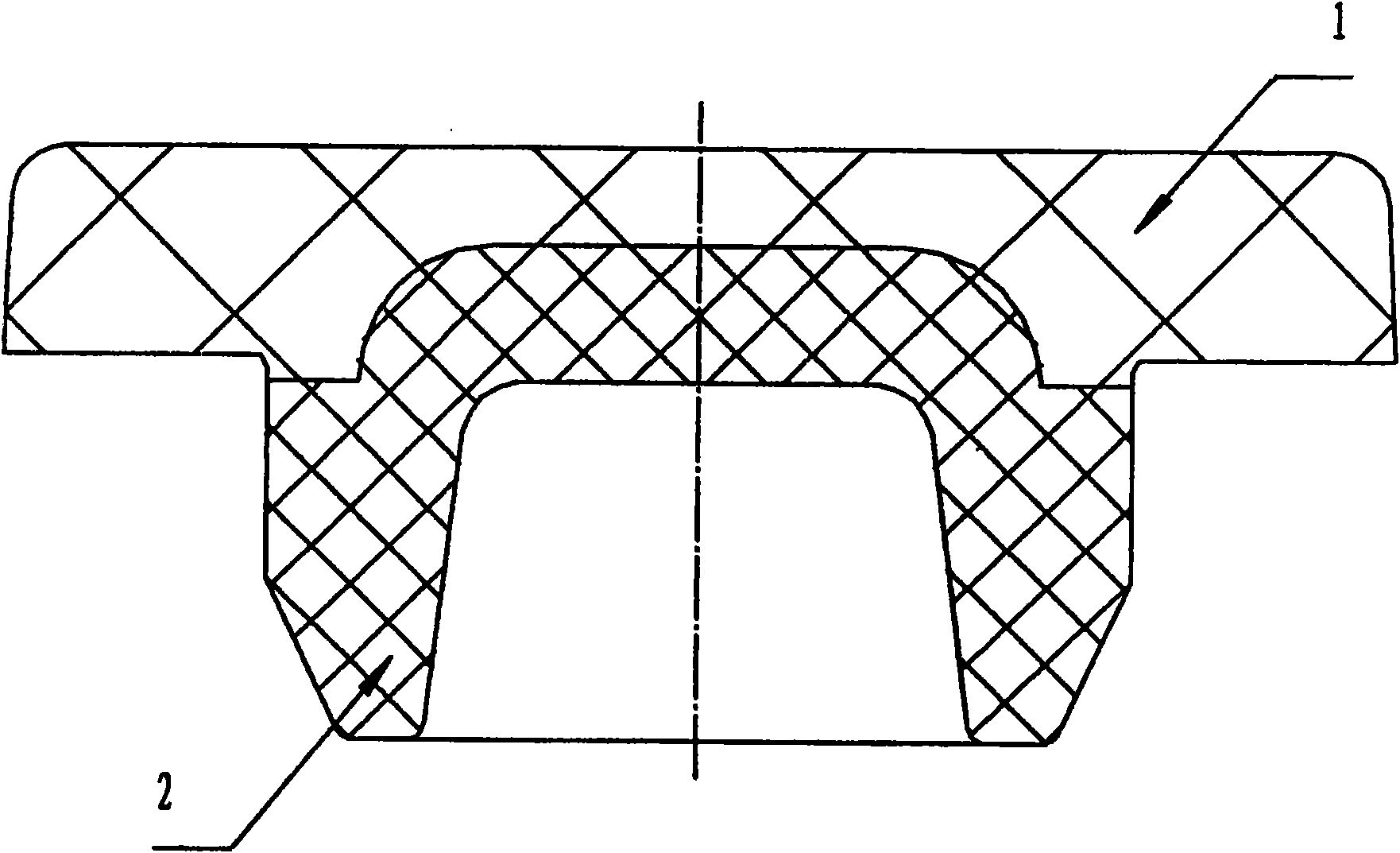

[0013] The first step is to place the elastomer film A in a vulcanizer. The elastomer film A is made of halogenated butyl rubber. The vulcanizer can be a vacuum vulcanizer, an ordinary molding vulcanizer, or an injection vulcanizer. The vulcanization temperature: 120°C-200°C, pressure 4-20Mpa. The vulcanization time is 3-8 minutes, and the vulcanized product is the part in contact with the drug, that is, the neck 2.

[0014] The second step is to remove the glue edge on the neck 2.

[0015] The third step is to put the plug neck 2 into the vulcanizing machine, and place the elastomer film B in the vulcanizing machine at the same time. The elastomer film B is made of isoprene rubber, propylene propylene rubber, styrene-butadiene rubber, and nitrile rubber. Or chloroprene rubber, the vulcanizing machine can be a vacuum vulcanizing machine, or an ordinary molding vulcanizing machine, or an injection vulcanizing machine, and the crown plug 1 is obtained from the elastic film B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com