Single-wall steel suspended box cofferdam

A technology of steel hanging box and cofferdam, which is applied in construction, infrastructure engineering and other directions, can solve the problems of increased demolition difficulty, high technical difficulty and high cost, and achieve the effect of improving demolition efficiency, reducing difficulty and reducing construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

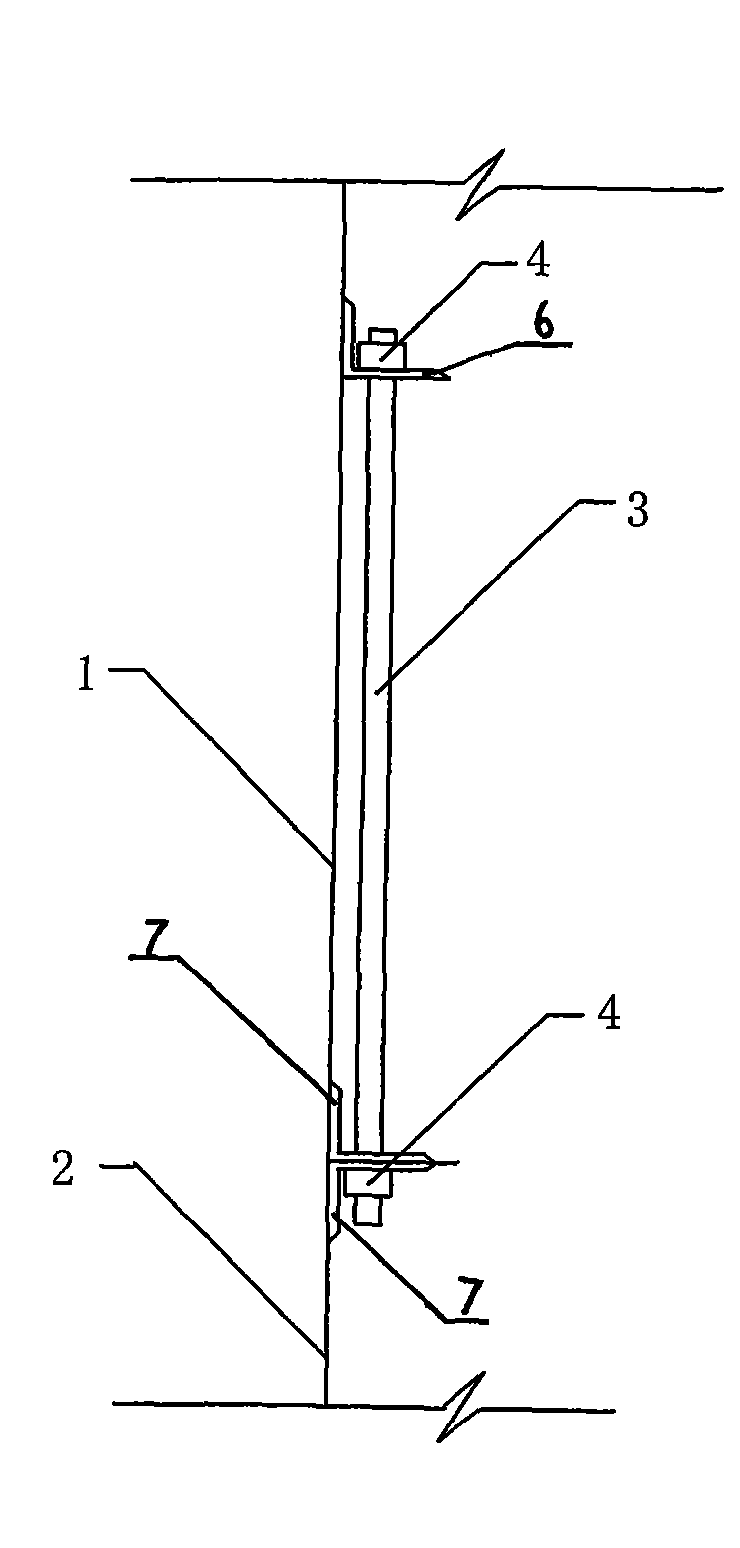

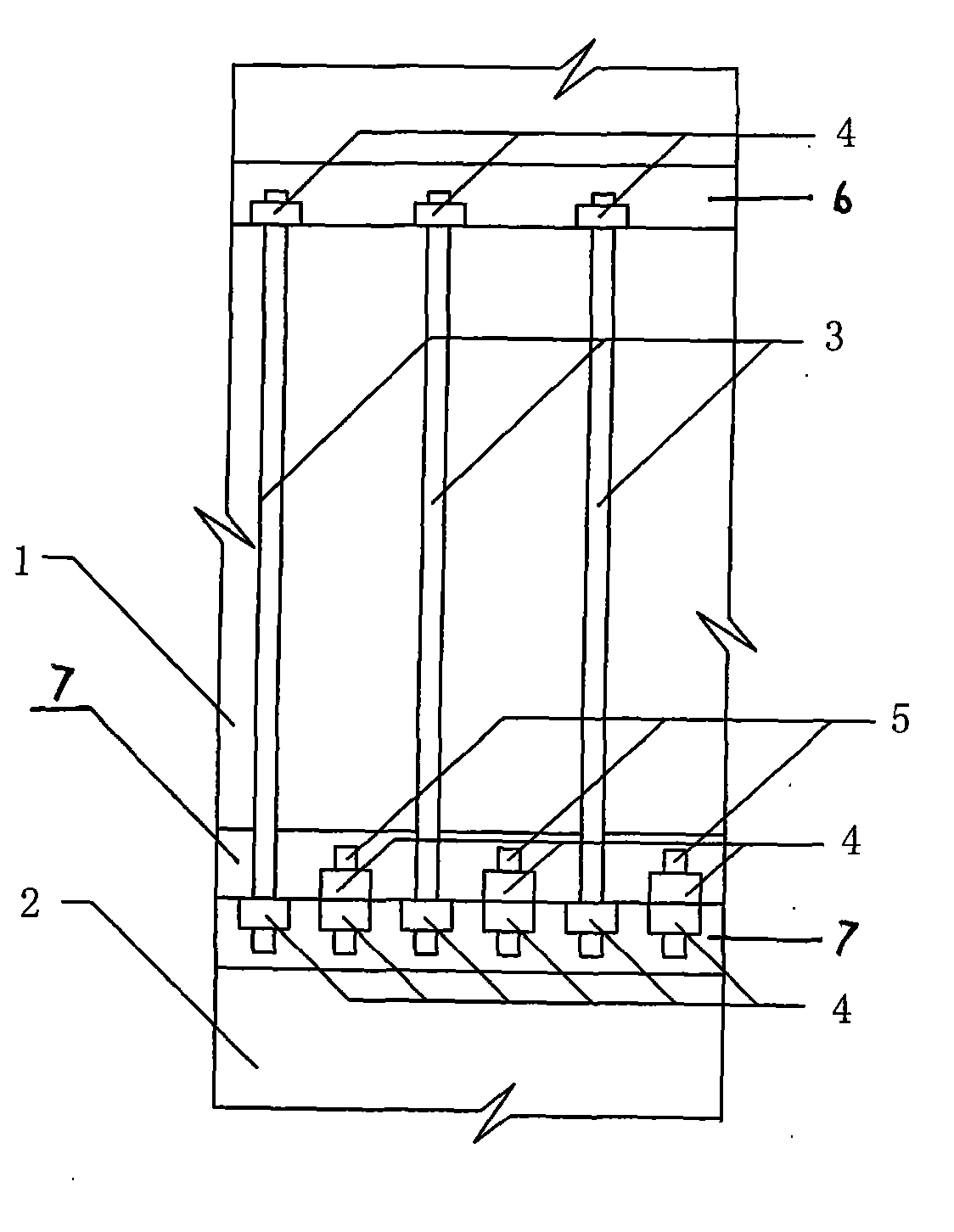

[0008] Single-wall steel hanging box cofferdam, including top section, bottom section, fasteners, bolts and nuts, fasteners are installed on the lower edge of the top section and the upper edge of the bottom section, and the top section and bottom section are fastened with bolts and nuts, It is characterized in that an upper fastener is installed on the upper edge of the top joint, and a screw hole is made on the upper fastener, and every other bolt is replaced by a screw, and threads are made at both ends of the screw, and the upper end of the screw passes through the upper fastener Fix the two ends of the screw hole made on the top with nuts, and fix the nuts at the lower end of the screw to the bottom section.

[0009] The invention is applied in the No. 40-No. 51 water pier in the construction of the Daliao River Bridge. The geometric dimensions of the single-wall steel hanging box cofferdam are: 14.78m×6.85m×6.9m.

[0010] During construction, the upper edge of the top se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com