Collector capable of automatically controlling gas separation for measuring production profile of oil well

A gas separation and production profile technology, applied in surveying, wellbore/well components, earth-moving drilling, etc., can solve the problems of large deviation, complex three-phase flow state of oil, gas and water, and meaningless measurement, etc. The effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with embodiment:

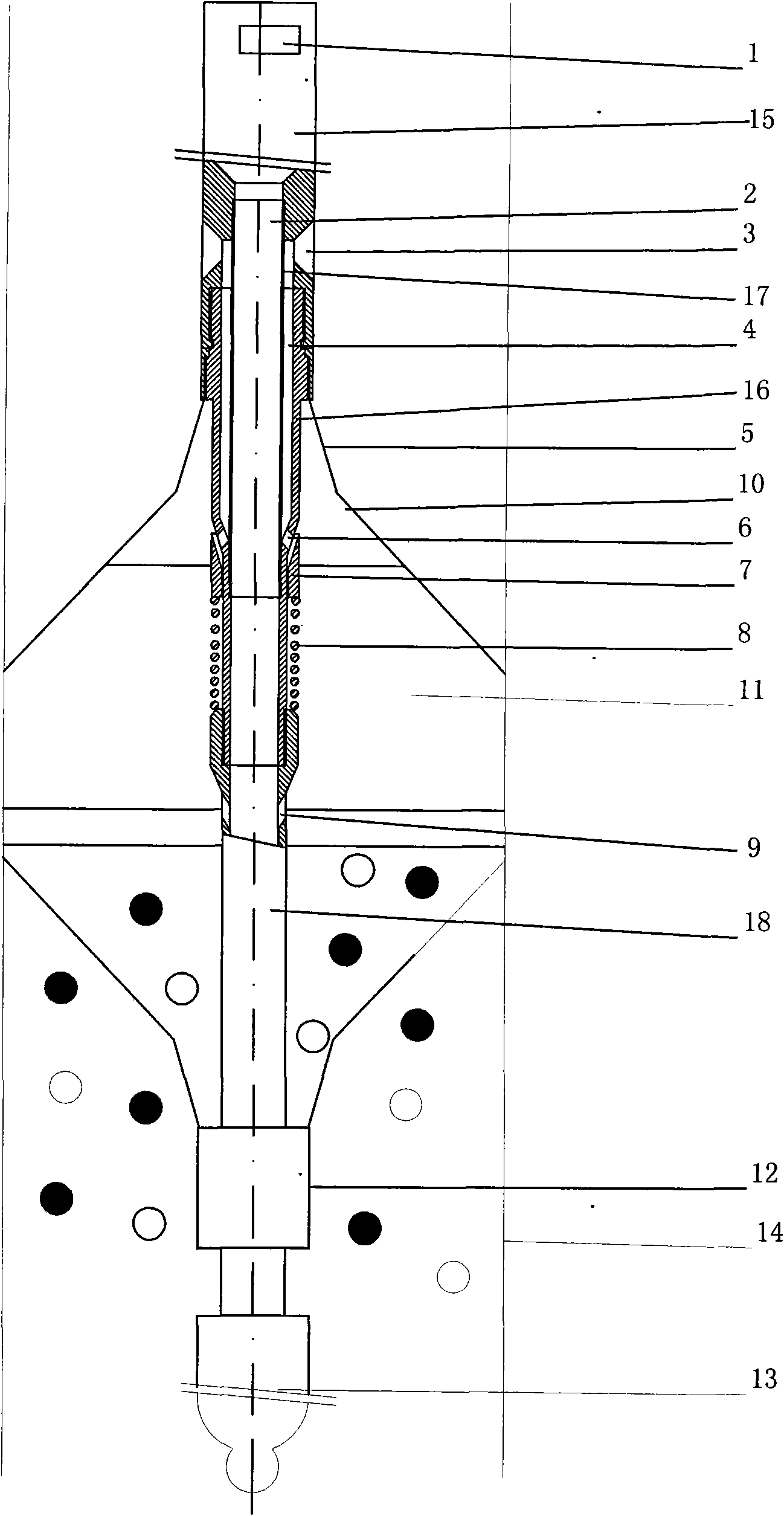

[0011] The automatically controllable gas separation type collector used for oil well production profile measurement includes an upper joint 15. The upper part of the hollow upper joint 15 has an oil-water outlet 1. The measured oil-water two-phase flows out from the oil-water outlet 1. The bottom of the upper joint 15 is connected to There is a collecting umbrella 5, and the middle part of the upper joint 15 is threadedly connected to the middle pipe 17, and the cavity at the bottom of the middle pipe 17 and the outer pipe 16 is the oil-water collecting channel 2. There is an outer pipe 16 outside the middle pipe 17, and the outer pipe 16 is threadedly connected with the upper joint 15 and the lower joint 18 respectively, and the bottom of the middle pipe 17 is threaded with the outer pipe 16, and there is an annular space between the outer pipe 16 and the middle pipe 17. The gas se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com