Light pipe clamp with smooth riveting base plate

A riveted and smooth technology, applied in the direction of pipes/pipe joints/fittings, pipe supports, mechanical equipment, etc., it can solve the problems of loose pipe clamps, insufficient stability and tightness of pipe clamps, causing danger, etc. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

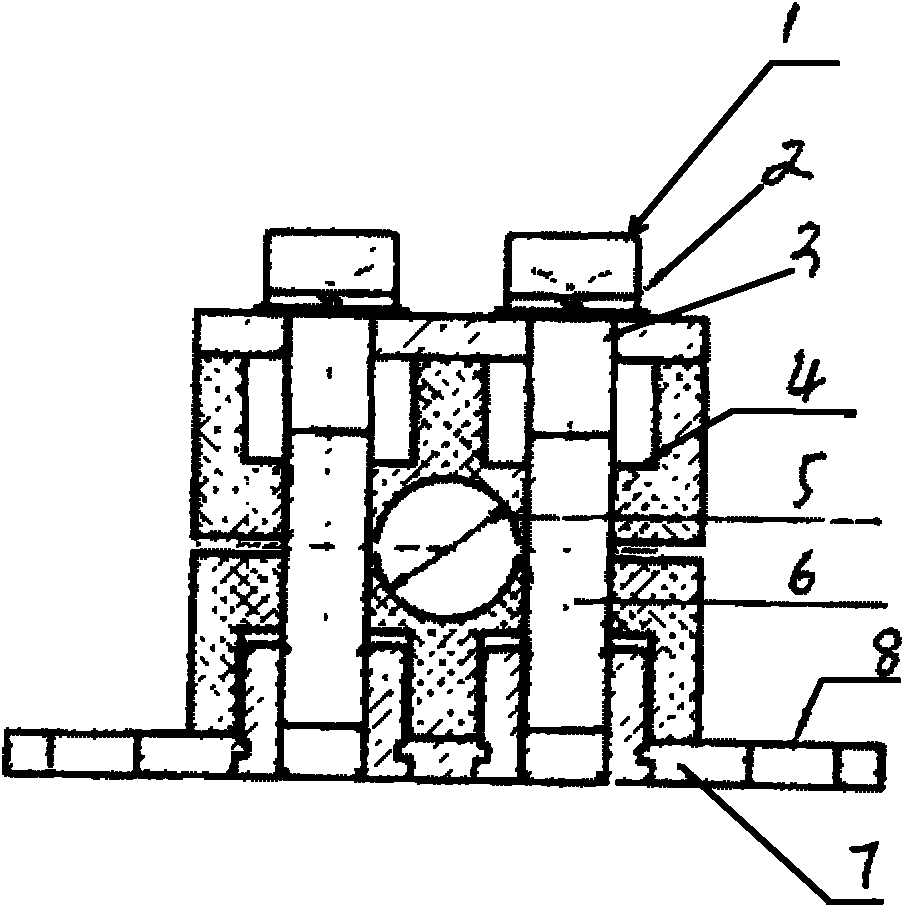

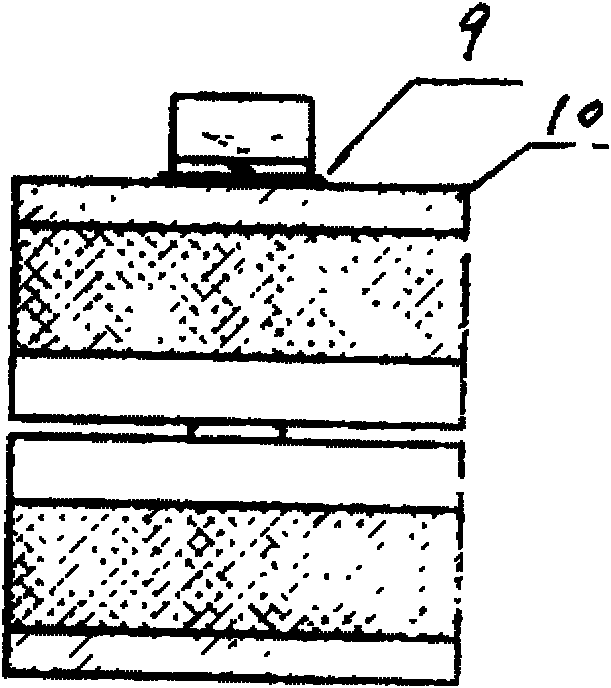

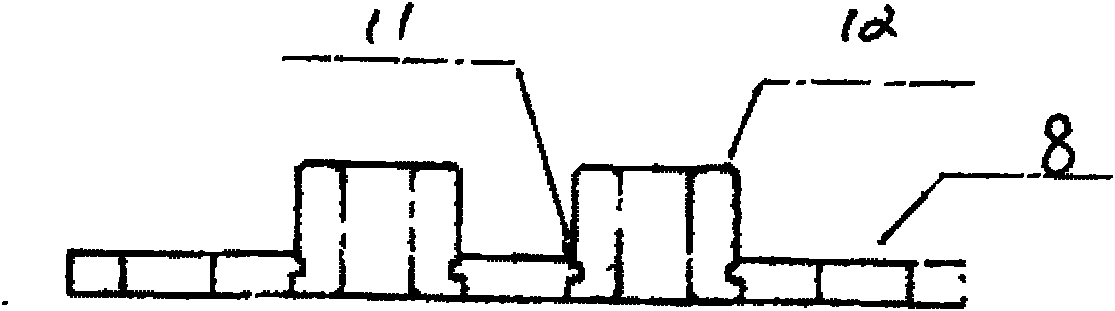

[0016] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] The smooth riveted floor light pipe clamp of the present invention includes a bolt 1, a spring pad 2, a cover plate bolt hole 3, a pipe clamp body 4, a pipe clamp hole 5, a pipe clamp body bolt hole 6, a riveted bottom plate 7, and a positioning hole 8 , flat washer 9, cover plate 10, anti-loosening bump 11, thread bubble 12, characterized in that the bolt 1 is sequentially inserted into the spring washer 2, flat washer 9, and the bolt 1 passes through the cover plate bolt hole 3, the pipe clamp After the body bolt hole 6, it is fixed on the riveted bottom plate 7 through the threaded bubble 12. The threaded bubble 12 is riveted together with the bottom plate through special pressure equipment and molds. The anti-loosening bump 11 is located between the bottom plate and the thread The riveting part of the bubble is used to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com