Method of extra-high voltage tension stringing

A tension stringing and ultra-high voltage technology, applied in the high-voltage field, can solve the problems of high safety risks, general operation effect of large-tonnage rotary connectors, and large force on the traction rope, and achieve the effect of reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] In order to enable those skilled in the art to implement the present invention better, the following first introduces the deployment process of the traction rope of the traction field.

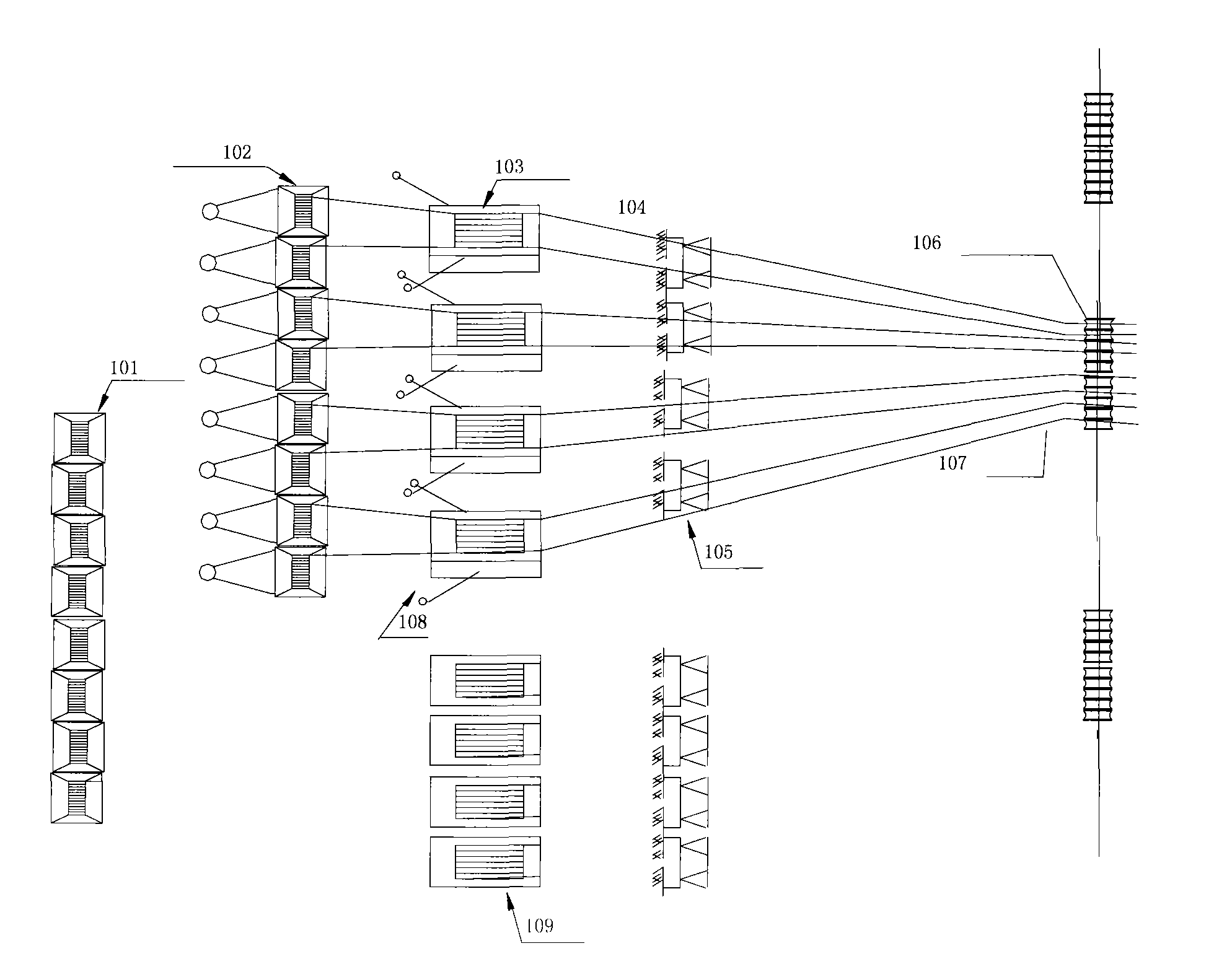

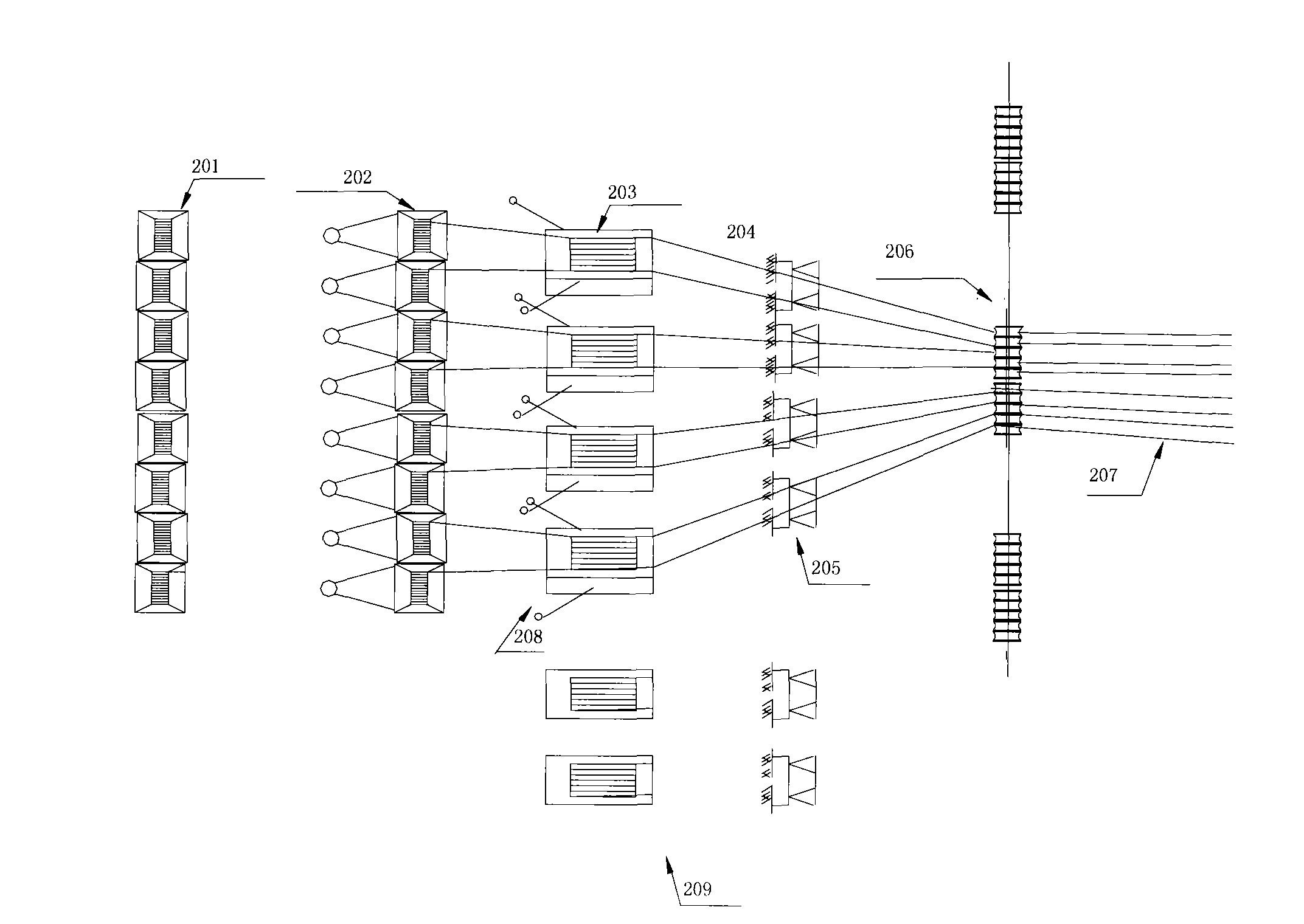

[0037] see figure 1 , which is a schematic diagram of the traction rope deploying equipment based on the traction field of the present invention.

[0038] Eight traction ropes enter the traction equipment through two five-wheel blocks 106. Traction equipment includes four two-line stretching machines.

[0039] figure 1 Eight 50KN ground anchors 104 are buried underground, and what is connected with the ground anchors 104 is a temporary anchor frame 105 . The anchor frame 105 is used for erecting the traction rope.

[0040] Eight traction ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter range | aaaaa | aaaaa |

| Diameter range | aaaaa | aaaaa |

| Diameter range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com