Liquid metal electromagnetic pump

A liquid metal and electromagnetic pump technology, applied in the field of electromagnetic pumps, can solve problems such as inability to meet the requirements of medium use, and achieve the effects of strong corrosion, high efficiency, and high working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

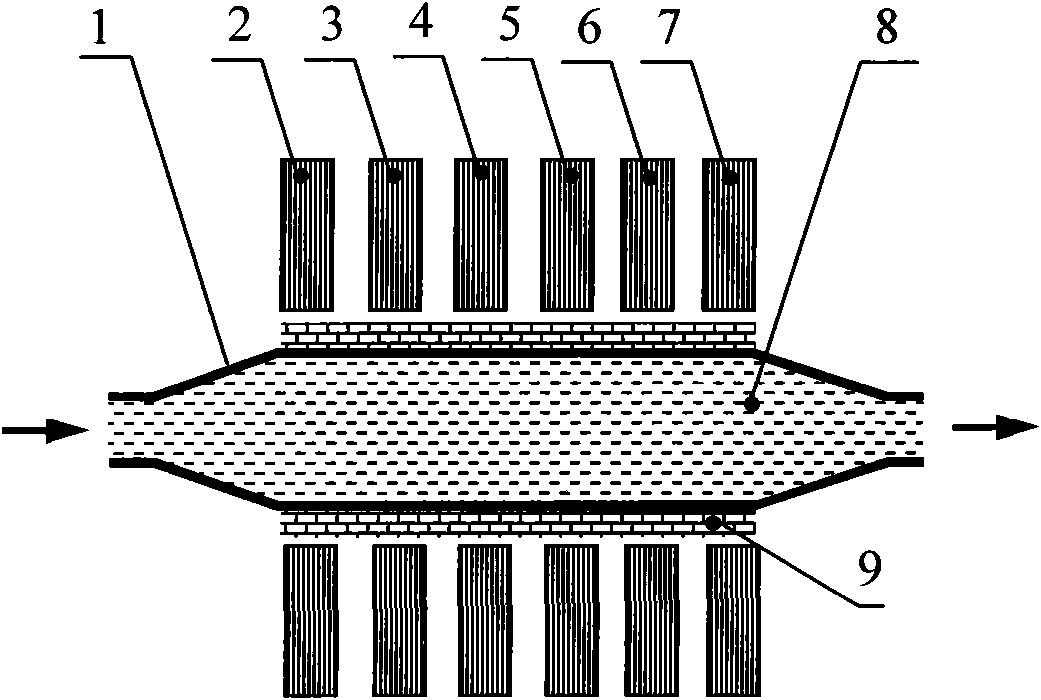

[0027] The liquid metal electromagnetic pump includes a pump ditch 1 and a control system. There are shrinkage openings at both ends of the pump ditch 1. An electromagnetic drive unit surrounds the pump ditch 1. The electromagnetic drive unit is formed by a first There are six groups of coils 2, 3, 4, 5, 6, and 7 to the sixth coil. The outer wall of the pump ditch 1 is covered with an insulation layer 9. The electromagnetic drive unit surrounds the outside of the insulation layer 9. The connection between the pump ditch 1 and the electromagnetic drive unit There is a gap between them, and the pump ditch 1 can be moved out freely. The first to sixth groups of coils are connected in delta. Each electromagnetic coil is wound by a hollow copper tube, the pump groove 1 vertically passes through the plane of the electromagnetic coil, and the cooling liquid passes through the hollow copper tube. Liquid metal 8 flows in the pump ditch 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com