Electronic equipment chassis

A technology of electronic equipment and chassis, applied in the direction of circuits, electrical components, electric solid devices, etc., to achieve the effect of good electromagnetic compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The device and method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

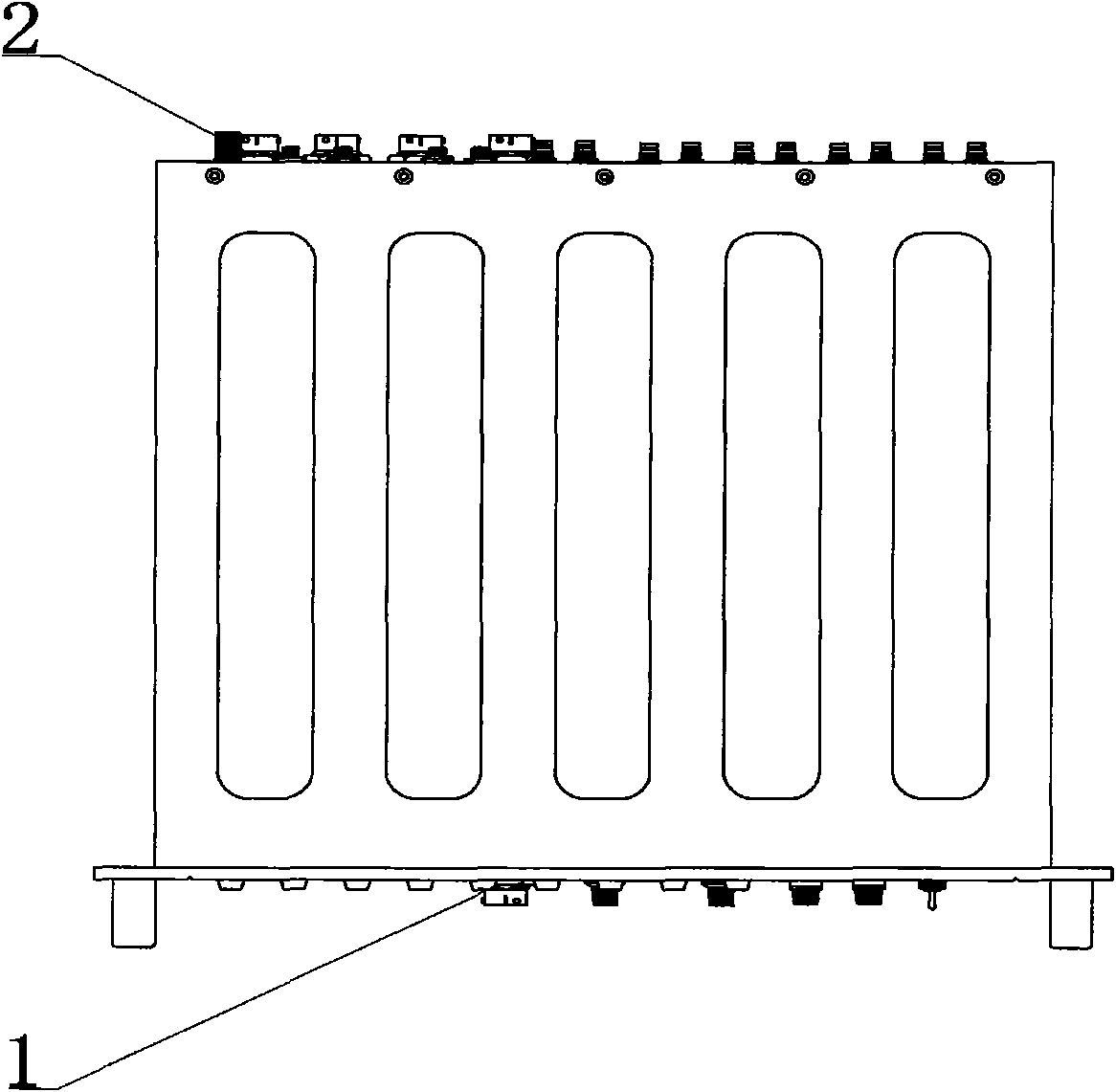

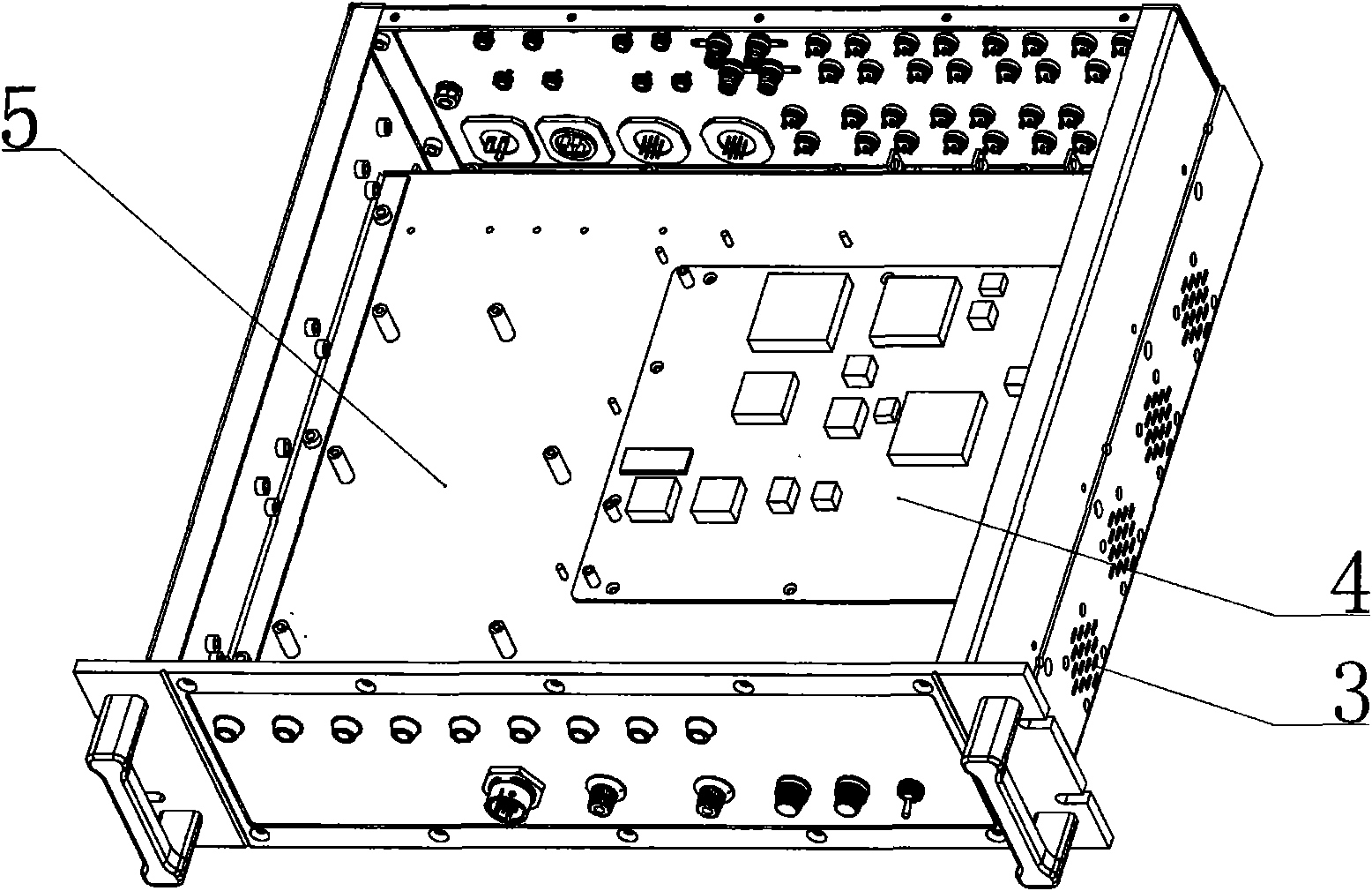

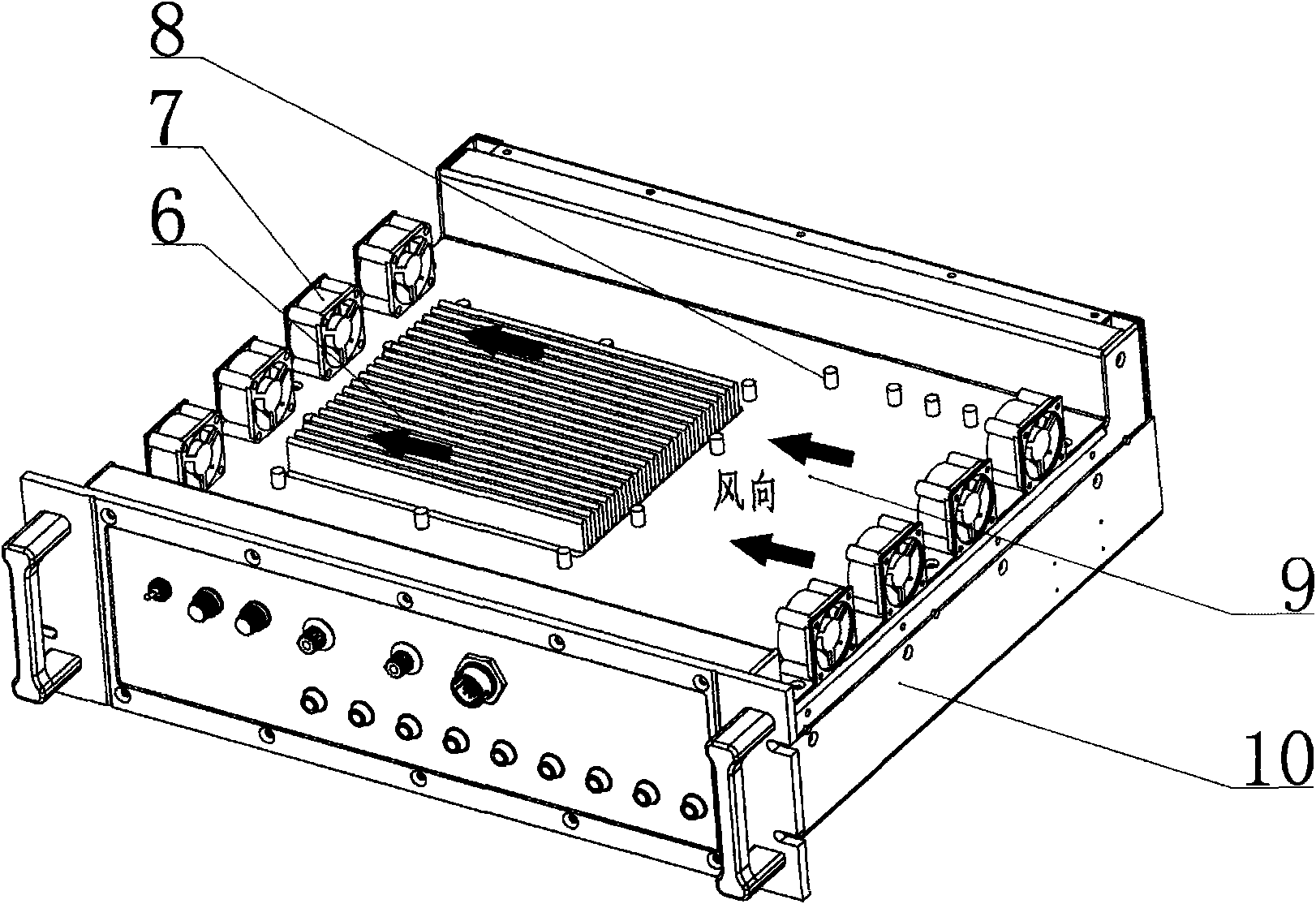

[0026] figure 1 It is a schematic diagram of the external structure of the electronic equipment chassis of the embodiment of the present invention, such as figure 1 As shown, the six surfaces of the external structure of the electronic equipment case are all made of metal materials, usually made of metals such as aluminum, copper, and iron with good thermal conductivity, or metal alloy materials such as copper alloys, aluminum alloys, and galvanized steel sheets. Wherein, the front panel 1 and the rear panel 2 of the chassis are provided with several through holes, the through holes are used to realize various interface functions, and corresponding device installation holes can be opened according to the functional requirements of the equipment. A part of the through holes is used to install c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com