Housing for accommodating at least one fuel cell stack

A fuel cell stack and housing technology, which is applied in the fields of fuel cells, fuel cell grouping, transportation fuel cell technology, etc. problems such as method realization, to achieve the effect of simple assembly, low-cost assembly device, and simple assembly device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

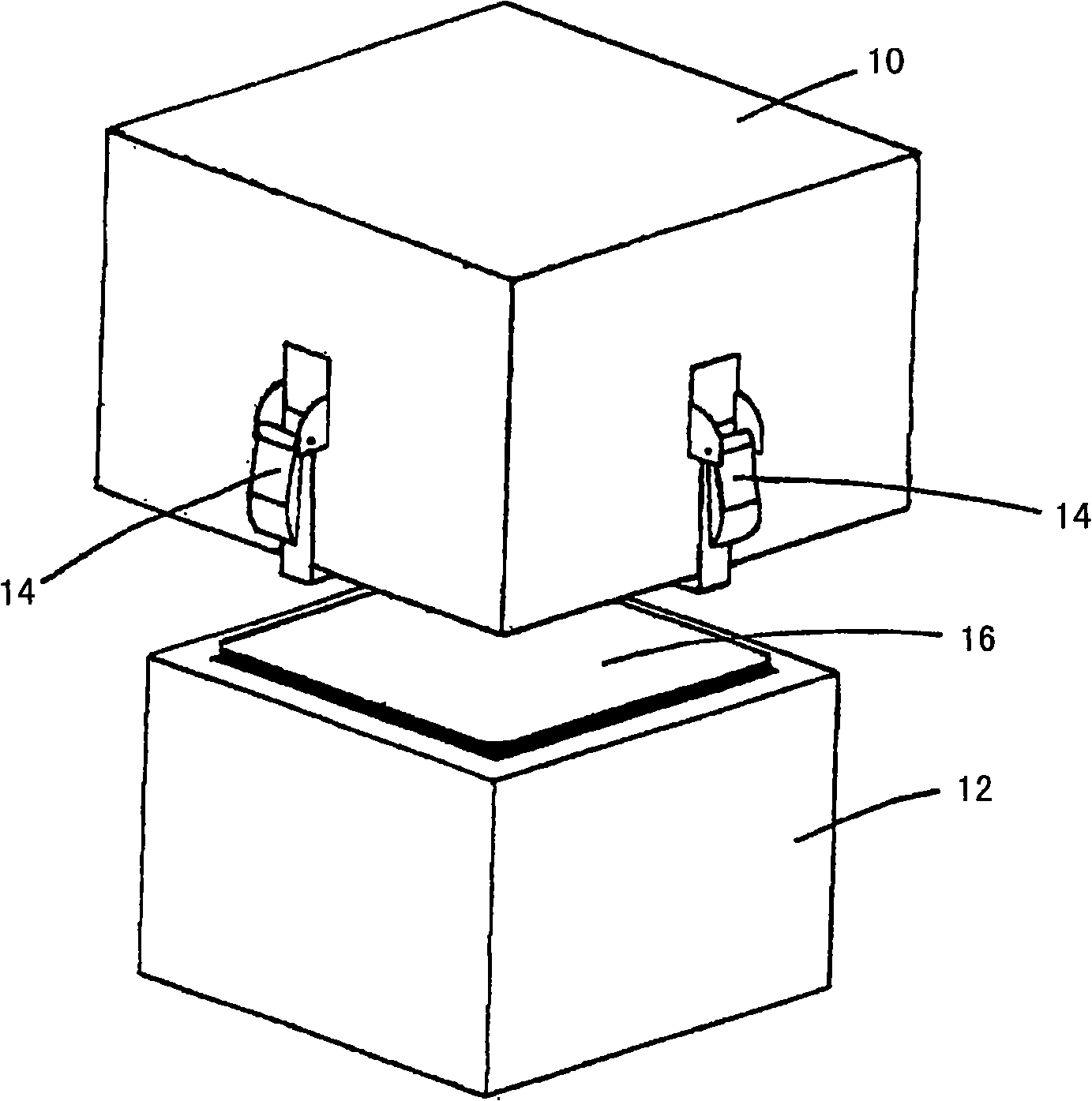

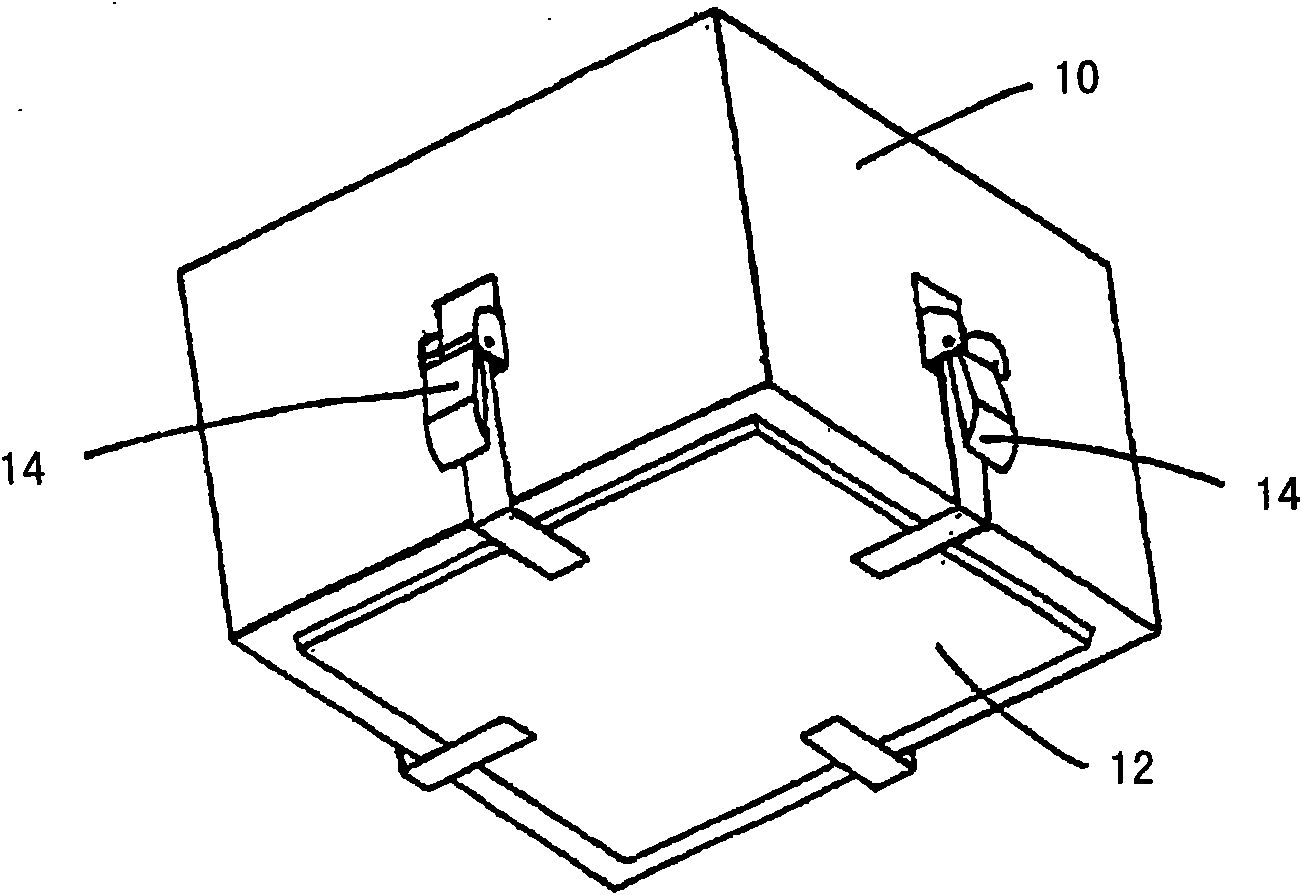

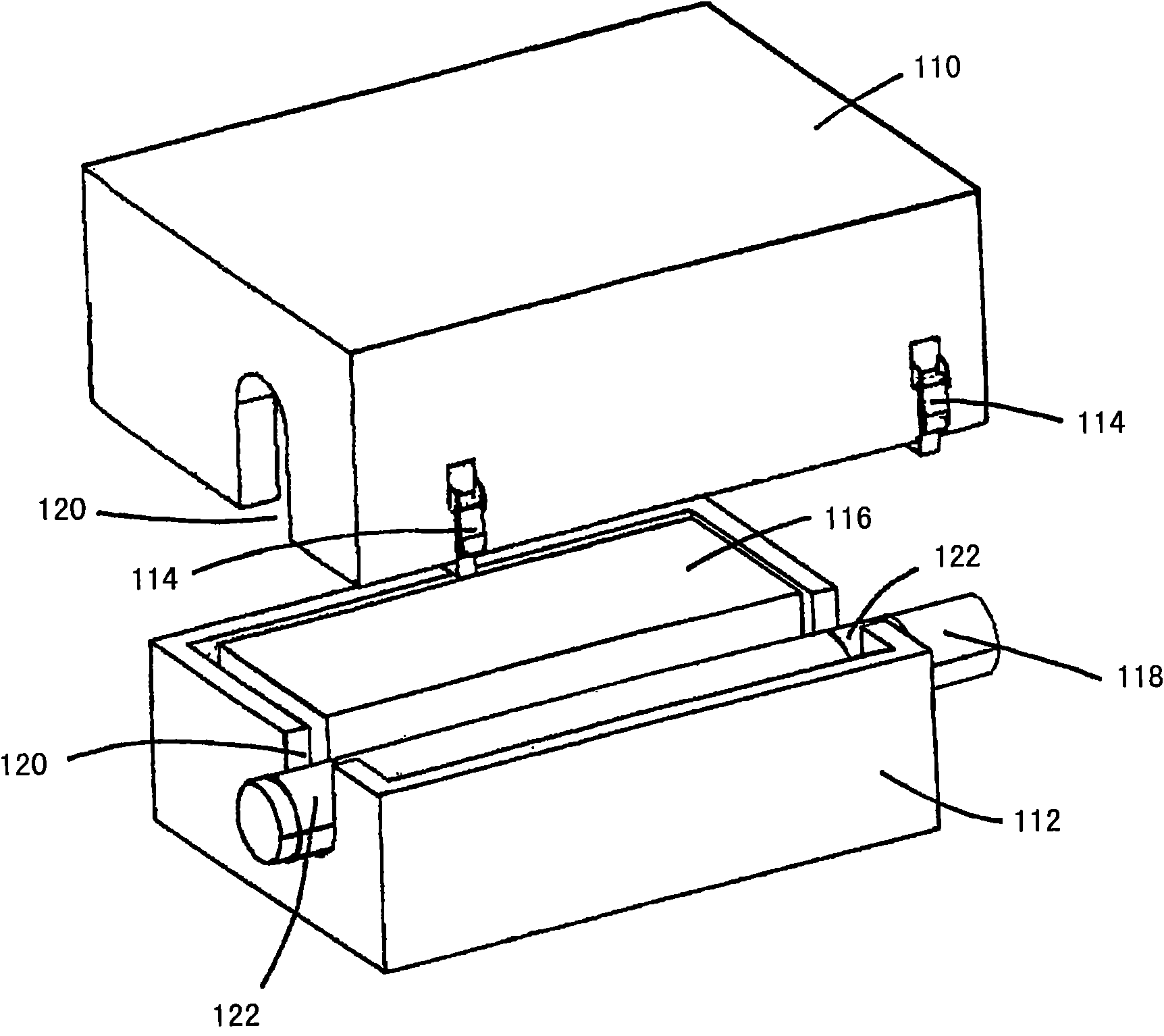

[0032] figure 1 with 2 A first embodiment of the housing according to the invention is shown, in which figure 1 shows the open state of the housing, while figure 2 The closed state of the housing is shown. The housing according to the invention comprises an outer enclosure shell 10 and an inner enclosure shell 12, said outer and inner enclosure shells being preferably made of insulating material. Further optionally, the outer enclosure shell 10 and / or the inner enclosure shell 12 are lined and / or coated with an insulating material on their outer sides. The two closure shells 10 , 12 are parallelepiped-shaped shells open at one end, which are dimensioned such that they nest into each other with an exact fit or without play. The outer closed shell 10 is provided with four hinged elastic clamps 14, and these four hinged elastic clamps are used as clamping devices. These hinged spring clips 14 are fixedly connected on the outside of the outer closure shell 10, so that the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com