Bamboo and plastic composite material and preparation method thereof

A composite material and bamboo-plastic technology, applied in the field of fiber material composition and its preparation, can solve the problems of poor compatibility and weak strength of bamboo-plastic composite materials, achieve low water absorption, improve compatibility, and protect the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

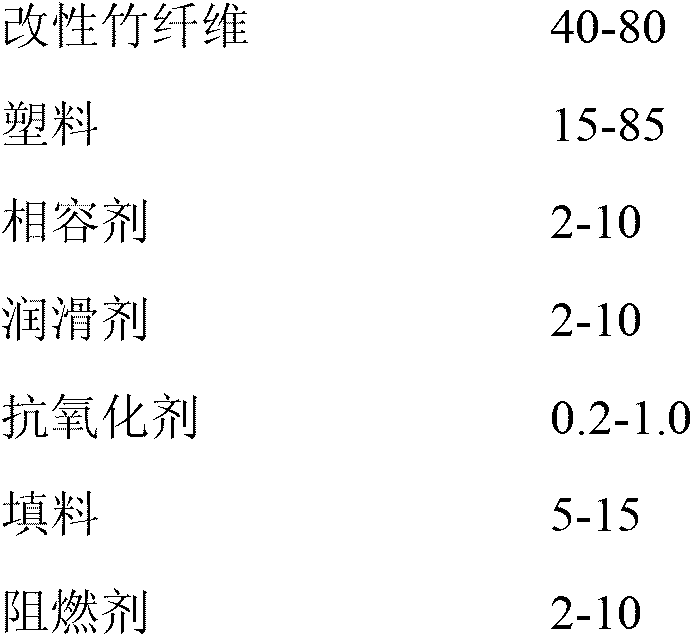

[0061] 1. Prepare materials according to the following proportions by weight:

[0062]

[0063]

[0064] Among them, the molecular weight of high-density polyethylene (HDPE) is 40,000-300,000, and the density is 0.93-0.97g / cm 3 , the melt index (MI, g / 10min) is 0.3-0.5; the molecular weight of maleic anhydride grafted polyethylene is 10000-300000, the grafting rate is 1-2%, and the melt index is 0.5-0.6g / 10min; the polyethylene wax The molecular weight is 2500-3000, the density is 0.92-0.94g / cm 3 , viscosity 0.7-1.2Pa·s (140°C); nitrogen content of ammonium polyphosphate is 22%-25%, phosphorus content ≥ 20%.

[0065] Wherein, the modified bamboo fiber is prepared according to the steps carried out in the following order:

[0066] A) Cut the bamboo into lengths of 20-40 mm, place it in a blaster (Beijing Forestry University; model: BL-08), open the pressure valve of the blaster, and inject saturated water vapor with a relative pressure of 3.0 MPa to blast. The relative...

Embodiment 2

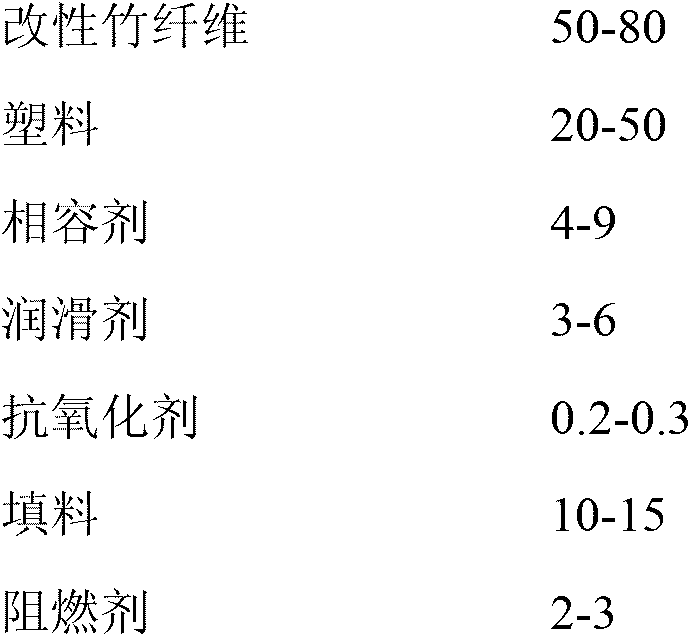

[0080] 1. Prepare materials according to the following proportions by weight:

[0081]

[0082] Wherein, the molecular weight of the polypropylene (PP) plastic is 10000-300000, the melt index (MI, g / 10min) is 0.2-1; the molecular weight of the maleic anhydride grafted polypropylene is 12000-300000, and the grafting ratio 1.5-2.5%, melt index 0.3-1.2g / 10min.

[0083] Wherein, the modified bamboo fiber is prepared according to the steps carried out in the following order:

[0084] A) Cut the bamboo into 20-40mm long bamboo material sections, place them in the blaster, open the blaster pressure valve, and feed saturated steam with a relative pressure of 3.0MPa to make the relative pressure in the blaster reach 4MPa. Keep it for 15 minutes, and steam the bamboo;

[0085] B) open the discharge valve of the blaster, make the bamboo raw material explode and spray into the normal pressure receiving container in an instant, and obtain the blasting bamboo fiber;

[0086] C) The ex...

Embodiment 3

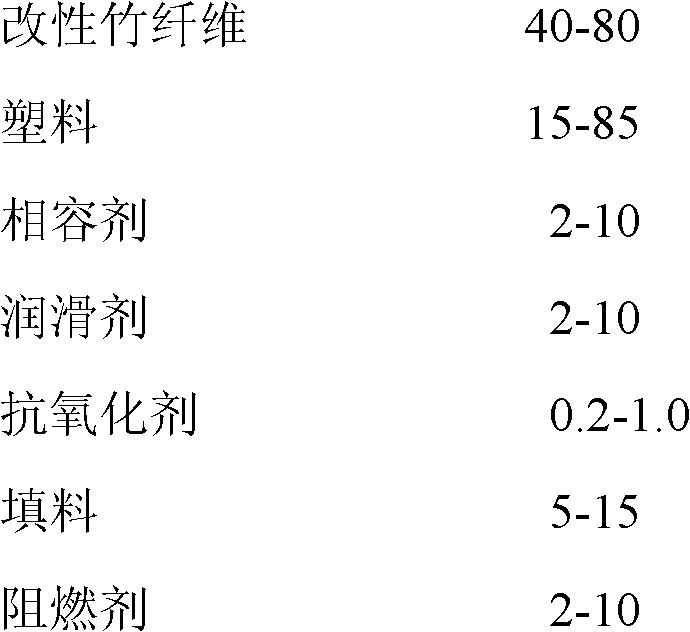

[0092] 1. Prepare materials according to the following proportions by weight:

[0093]

[0094] Among them, the molecular weight of high-density polyethylene (HDPE) is 40,000-300,000, and the density is 0.94g / cm 3 , the melt index (MI, g / 10min) is 0.3-0.5; the molecular weight of maleic anhydride grafted polyethylene is 10000-300000, the grafting rate is 1-2%, and the melt index is 0.5-0.6g / 10min; The molecular weight is 800-1300, and the chlorine content is 40-70%.

[0095] Wherein, the modified bamboo fiber is prepared according to the steps carried out in the following order:

[0096] A) Cut the bamboo material into 20-40mm long bamboo material sections, place it in the blaster, open the blaster pressure valve, and feed saturated water vapor with a relative pressure of 3.0MPa to make the relative pressure in the blaster reach 2.5MPa. Keep it for 30 minutes, and steam the bamboo;

[0097]B) open the discharge valve of the blaster, make the bamboo raw material explode a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com