DC motor

A DC motor and magnetic yoke technology, applied in the field of DC motors, can solve problems such as generating electrical noise, and achieve the effects of increasing the duty cycle, realizing miniaturization, and reducing large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

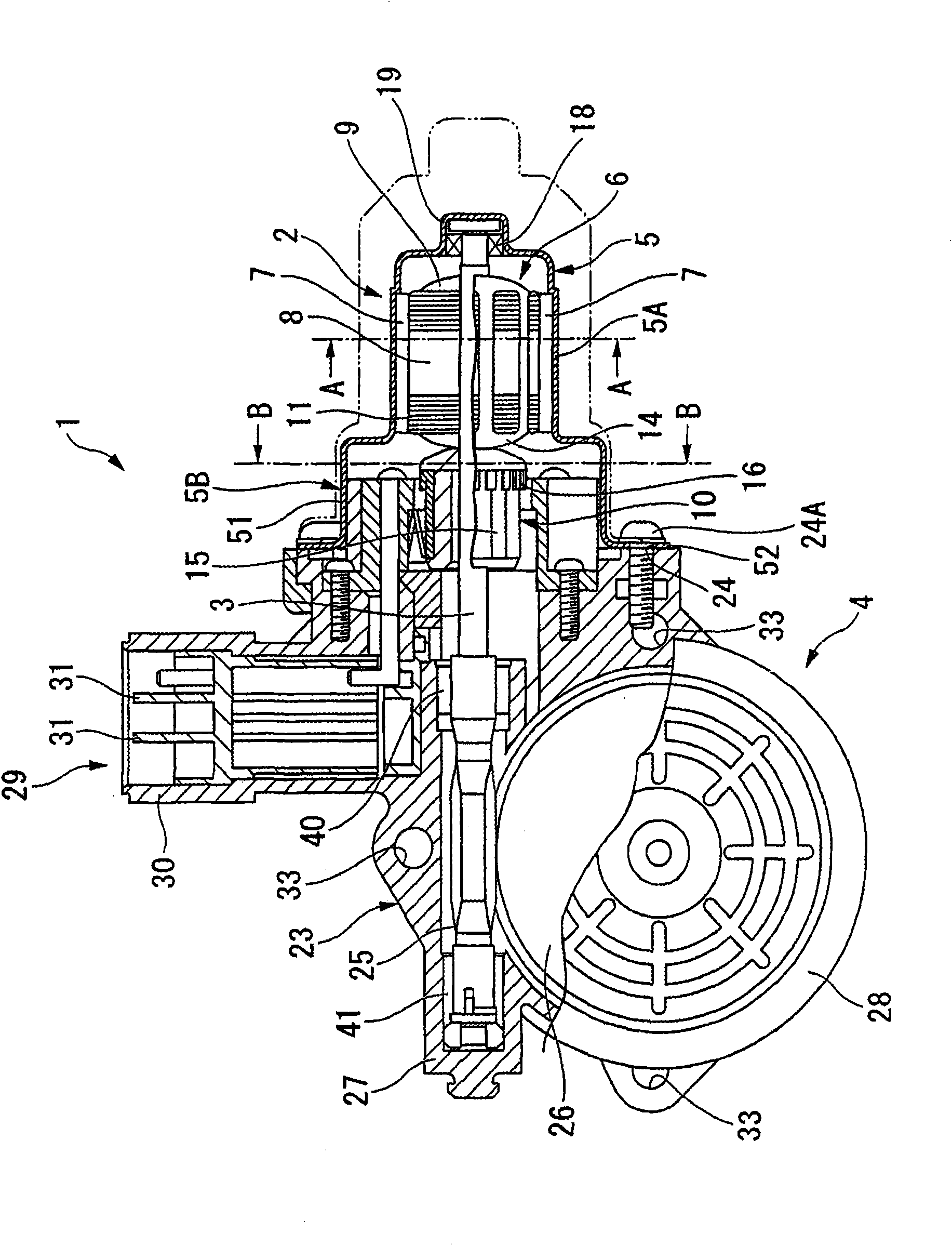

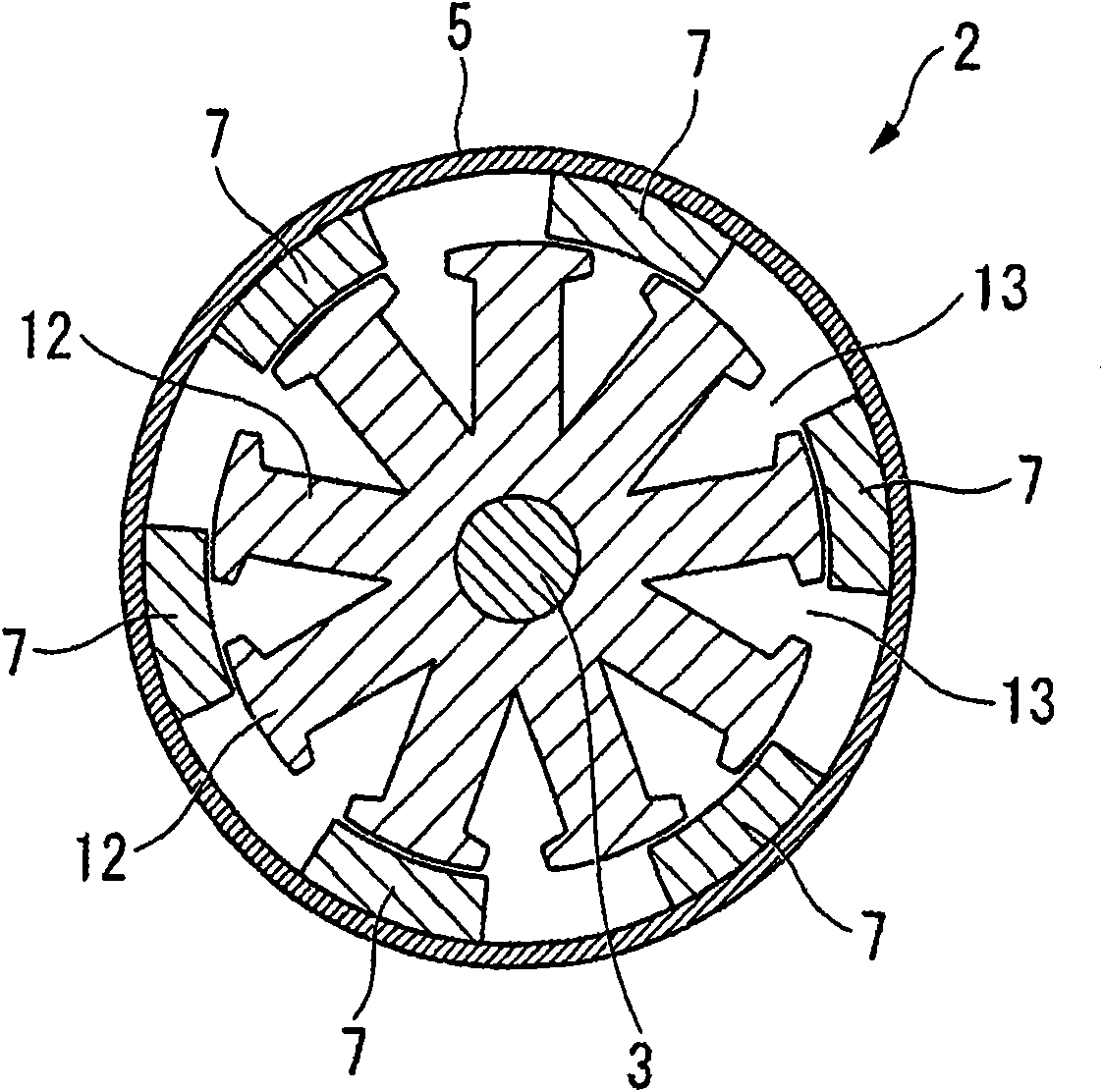

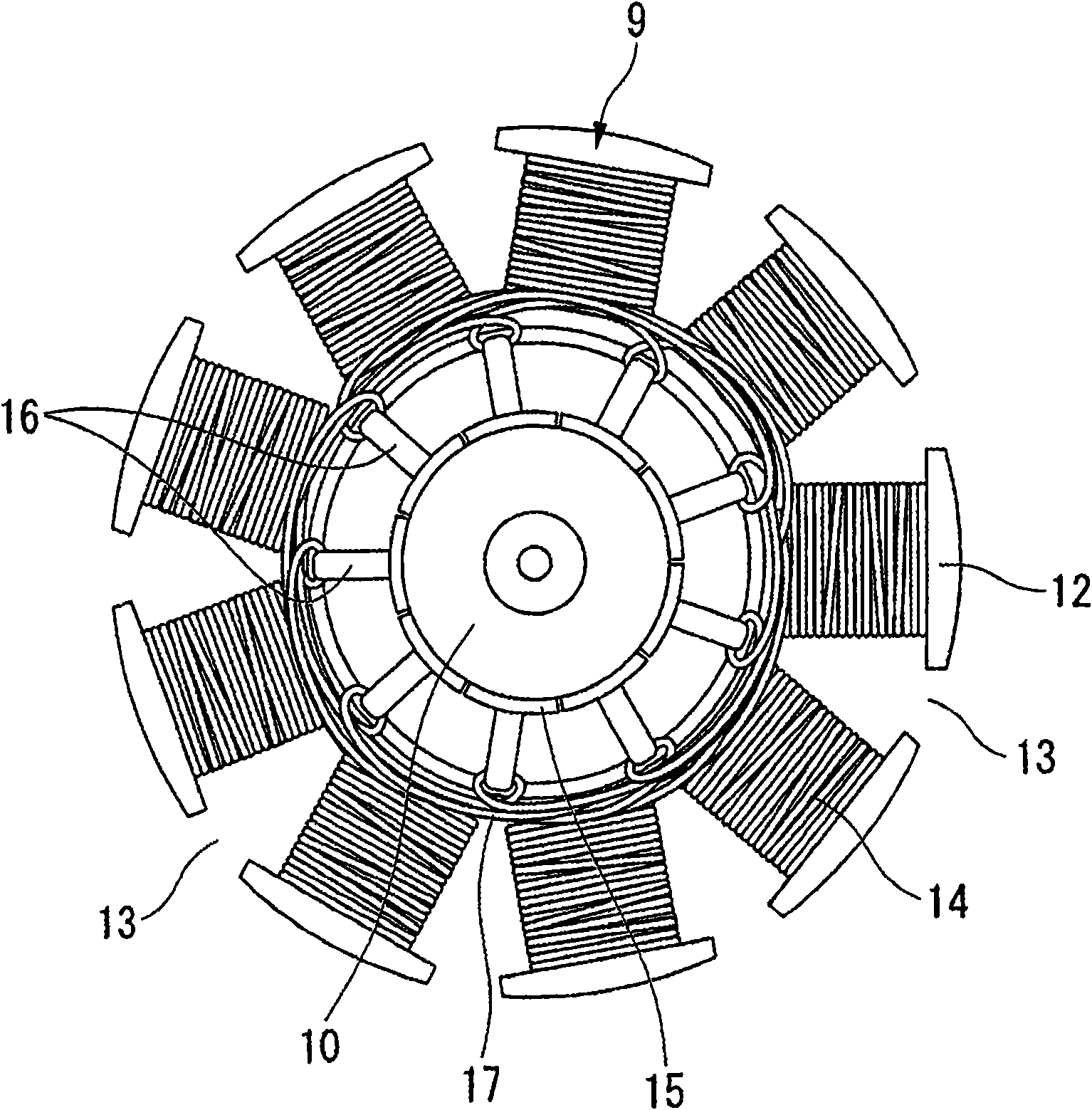

[0075] figure 1 It is a sectional view showing the structure of the automatic window device 1 for a vehicle using the DC motor 2 according to the present invention, figure 2 is along figure 1 A sectional view of the A-A line, image 3 is a top view of the armature 6, Figure 4 is along figure 1 B-B line sectional view.

[0076] Such as Figure 1 ~ Figure 4 As shown, the automatic window device 1 has a structure including a DC motor 2 and a worm gear reducer 4 connected to a rotating shaft 3 of the DC motor 2, and is incorporated in a door (not shown) of a vehicle. In addition, the two-dot chain line described around the DC motor 2 is a line showing the external shape of a conventional DC motor for comparison with the DC motor 2 of the present invention.

[0077] The DC motor 2 has a structure in which an armature 6 is rotatably arranged in a yoke case 5 having a bottomed cylindrical yoke main body 5A. Six shoe-shaped permanent magnets 7 divided in the circumferential d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com