Multi-directionally preformed braided part and three-dimension integrally braiding method thereof

A technology of integral weaving and knitting, which is applied in the direction of braiding, textiles and papermaking, etc. It can solve the problems of weak connection, distortion of heel knuckles, no consideration, etc., and achieve improved connection strength, uniform knuckles, and better connection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0075] A multi-directional preformed braid (see Figure 4 Shown) as an example, illustrate the three-dimensional integral braiding method of the multi-directional preformed braid provided by the present invention, comprising the following steps:

[0076] Step 1. Determine the molding direction and its sequence:

[0077] In this embodiment, the longitudinal direction of the rectangular flat plate 20 should be taken as the first forming direction I, and the axial direction of the circular tube 21 should be taken as the second forming direction II.

[0078] Step 2. Determine the position of the theoretical intersection line 22:

[0079] The theoretical intersection line is a closed curve corresponding to the edge position of the intersection line of the two components;

[0080] 1) According to the predetermined diameter of the circular tube 21 and the design position, calculate the position of the theoretical intersection line 22 where the circular tube 21 intersects with the r...

no. 2 example

[0101] With the multi-directional preformed braid (referring to Figure 11 ) as an example to illustrate the three-dimensional integral knitting method of the multi-directional preformed braid provided by the present invention. Since the second embodiment is very similar to the first embodiment, in order to save space, a brief description is given for the parts with little difference. Described three-dimensional overall braiding method comprises the following steps:

[0102] Step 1. Determine the molding direction and its sequence:

[0103] In this embodiment, the longitudinal direction of the rectangular flat plate 30 is still the first forming direction I, and the axial direction of the circular tube 31 is the second forming direction II. The first forming direction can be aligned with the circular tube 31 on the rectangular flat plate 30 The orthographic directions of are parallel or not parallel.

[0104] Step 2. Determine the position of the theoretical intersection lin...

no. 3 example

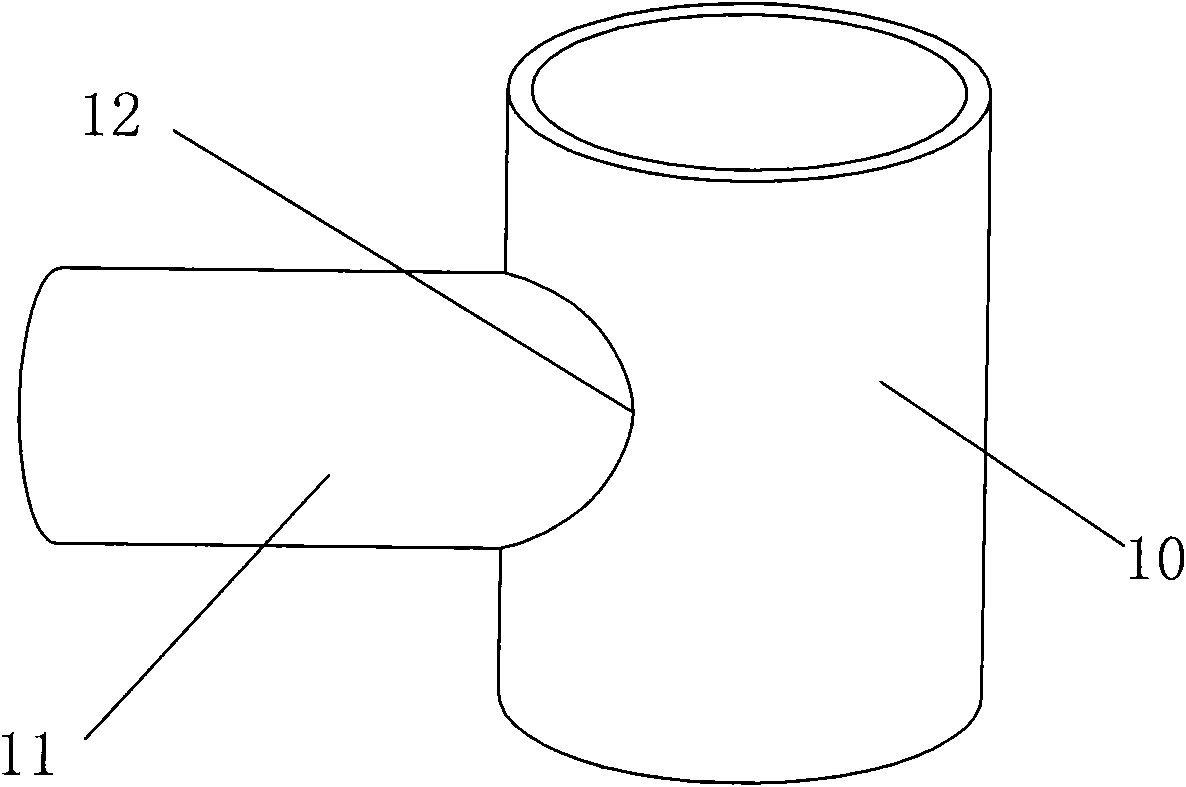

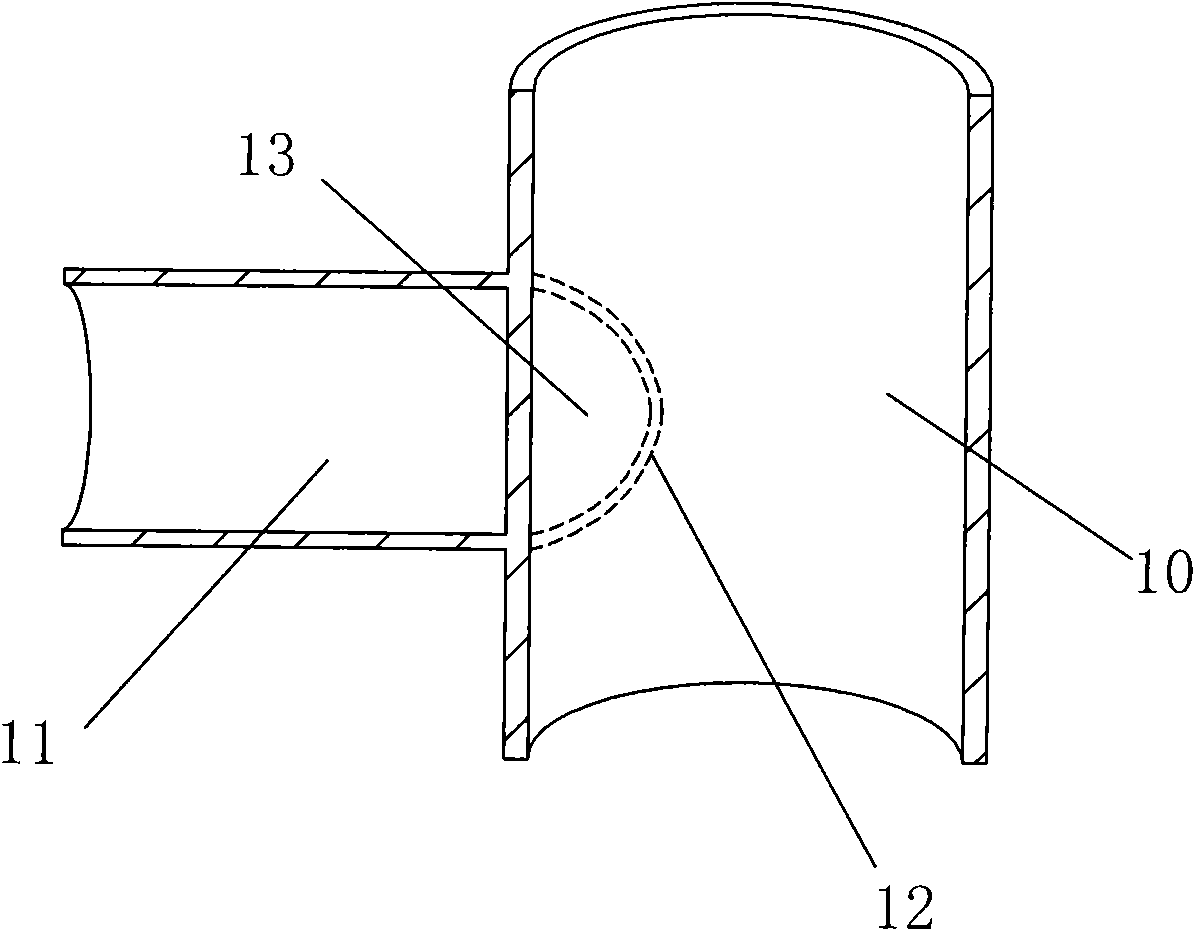

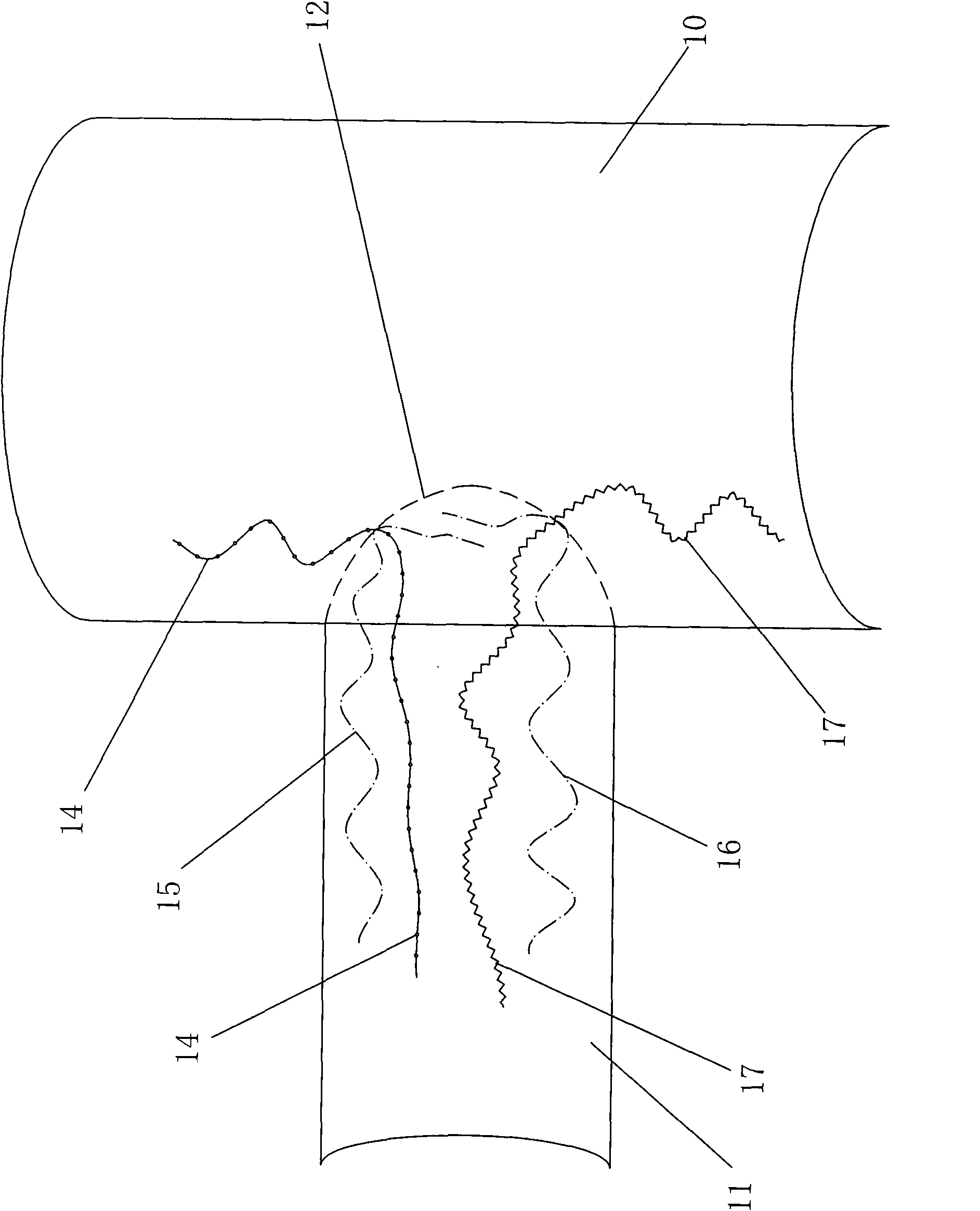

[0115] A multi-directional preformed braid consisting of two tubular bodies diagonally intersected (see Figure 15 Shown) as an example, illustrate the three-dimensional integral braiding method of the multi-directional preformed braid provided by the present invention, comprising the following steps:

[0116] Step 1. Determine the molding direction and its sequence:

[0117] In this embodiment, the diameters of the two pipe bodies are different, the larger diameter is called the main pipe 40, and the smaller diameter is called the branch pipe 41, then the length direction of the main pipe 40 should be taken as the first forming direction I, and the axis of the branch pipe 41 should be The direction is the second forming direction II.

[0118] In addition, if the diameters of the two pipe bodies are the same, the pipe body whose both ends can extend outward is the main pipe, and the other is the branch pipe.

[0119] Step 2. Determine the position of the theoretical intersec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com