Water sealing method for civil engineering groundwork

A technology of civil engineering and water stop, applied in the direction of foundation structure engineering, building, sheet pile wall, etc., can solve the problems of gravel layer, crushed stone layer, pebble layer water stop, project cost impact, high water permeability and other problems , to achieve the effect of simple construction, low price and simple construction machinery

Inactive Publication Date: 2010-12-01

陆观宏

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It can be seen from the above that the conventional water-stopping methods have their own advantages and disadvantages. Except for the underground diaphragm wall method, none of them can solve the water-stopping problem of the gravel layer, crushed stone layer, and pebble layer. The water permeability of the gravel layer, crushed stone layer, and pebble layer Very large, often determines the success or failure of the project, and also has a great impact on the project cost

Although the underground diaphragm wall method can solve the problem, the cost of the underground diaphragm wall method is too high, and general construction units cannot accept it at all.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

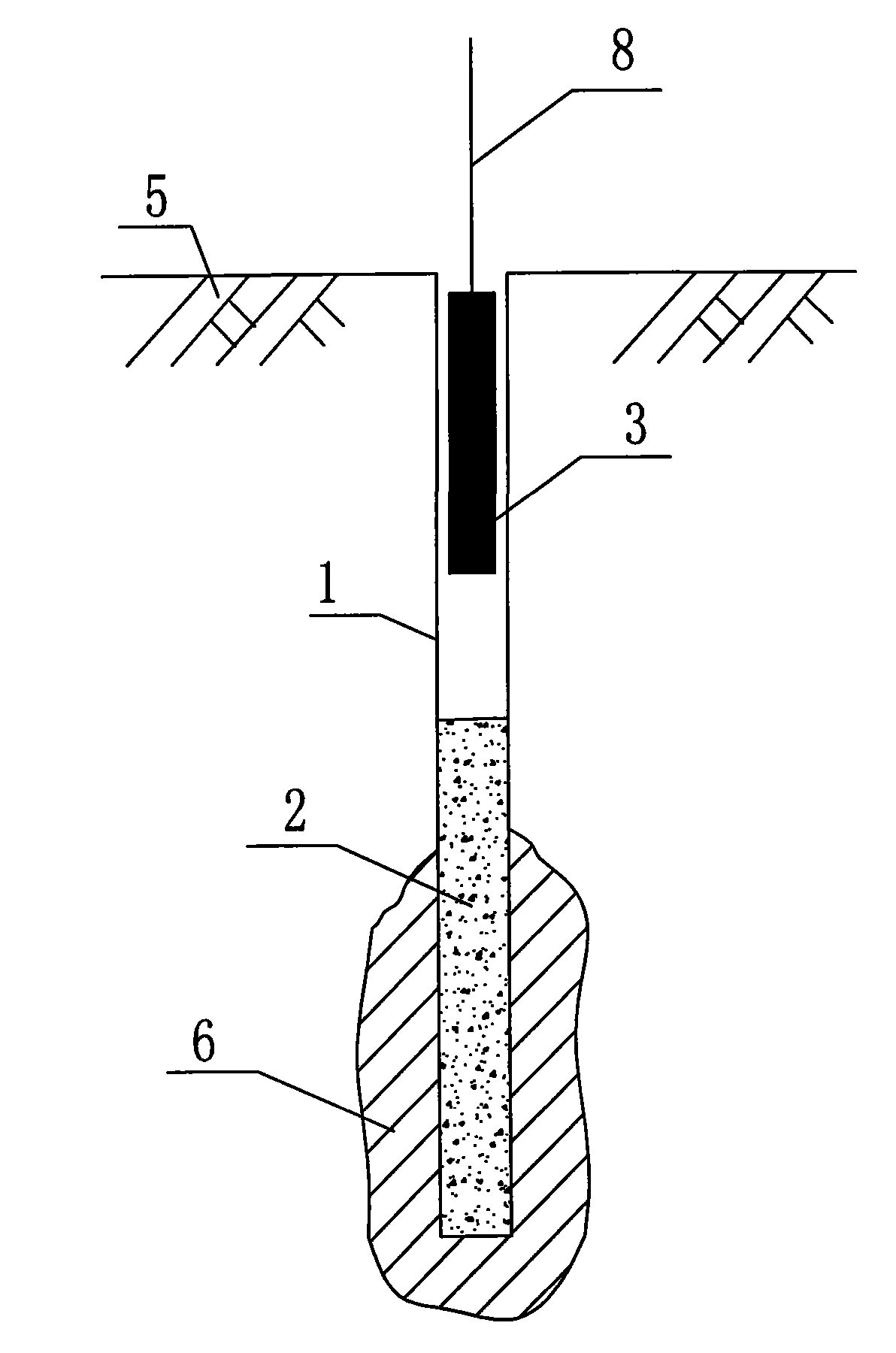

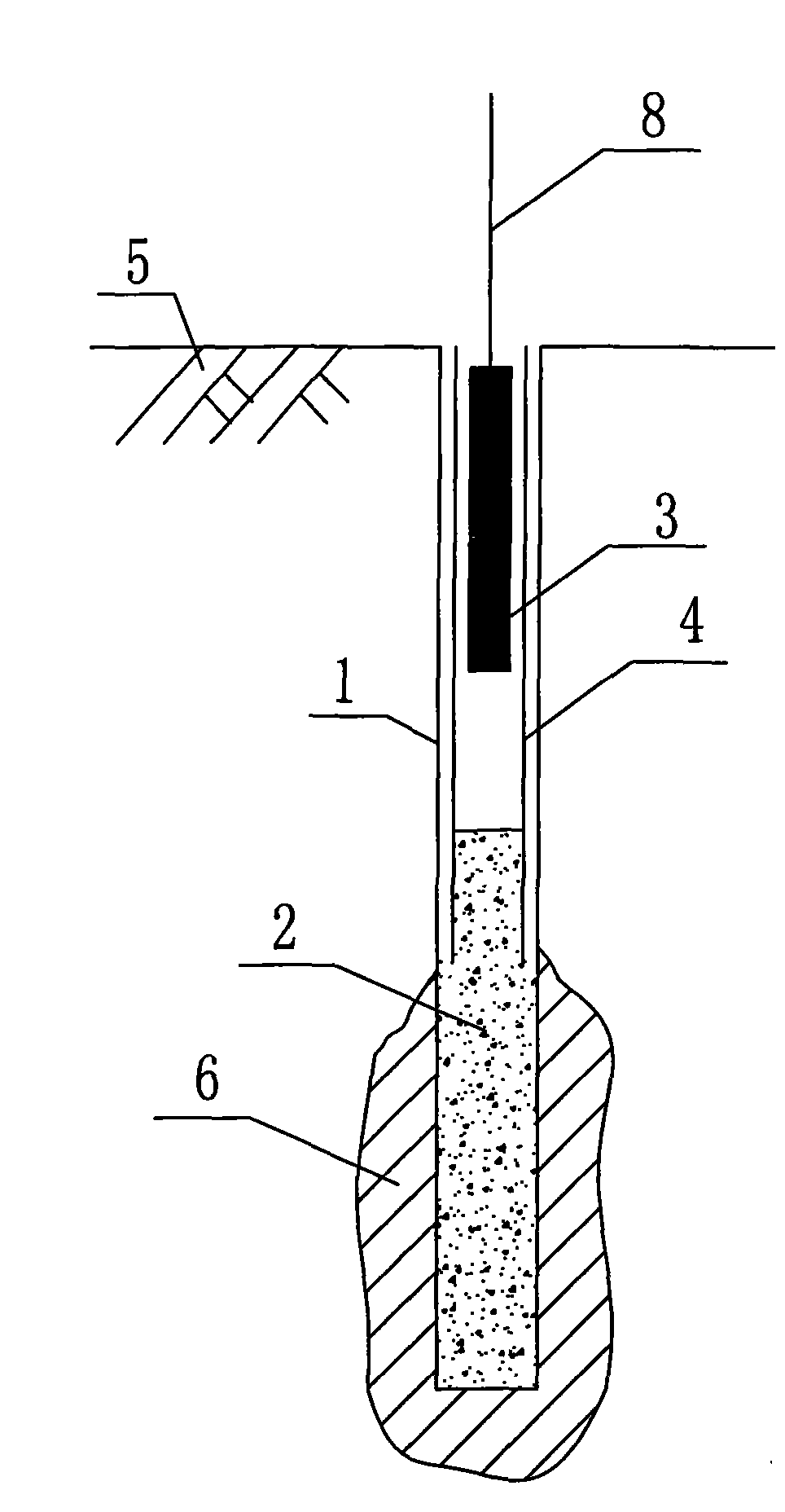

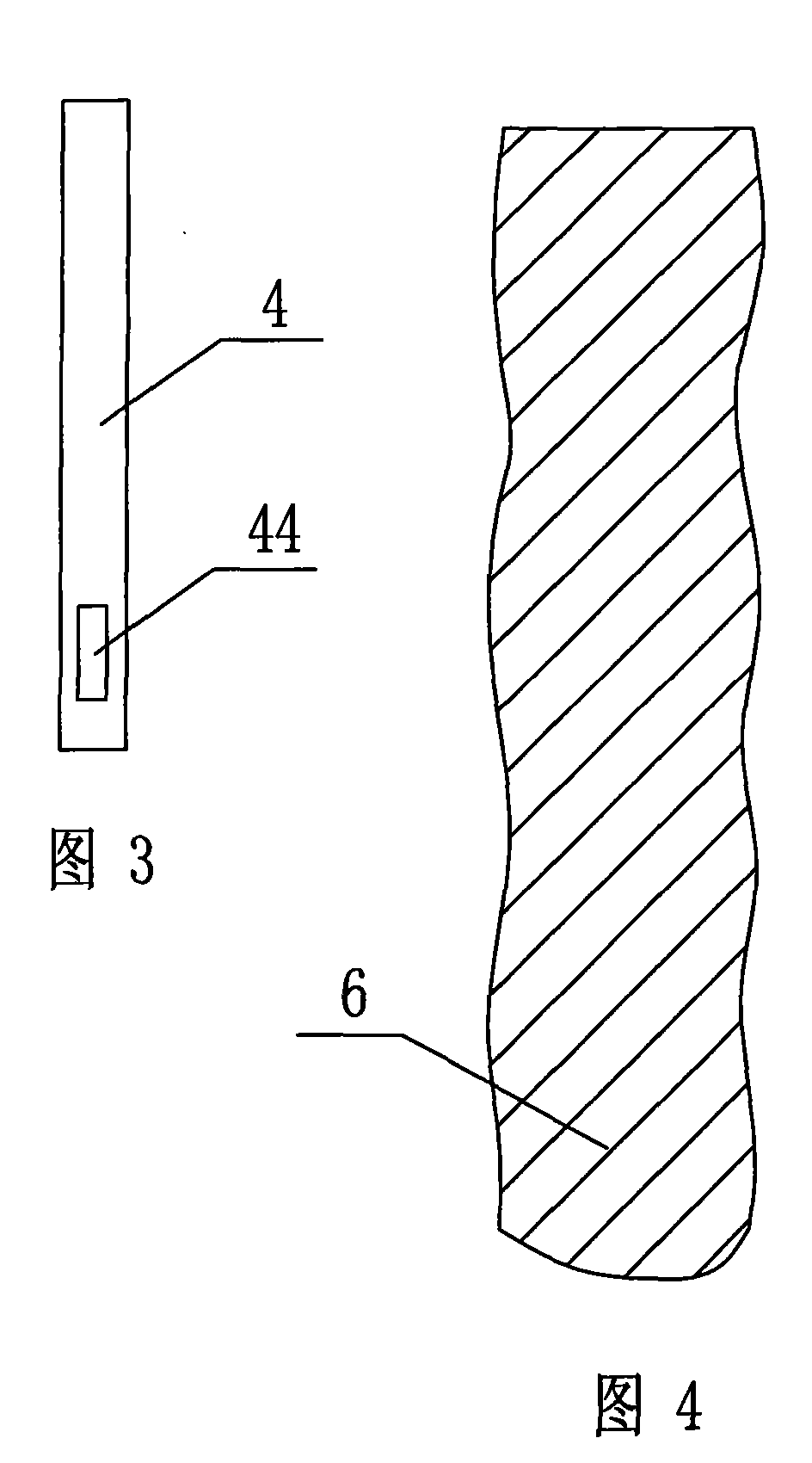

The present invention discloses a water sealing method for a civil engineering groundwork, belonging to a water sealing technology field of the civil engineering, including the following steps: (A) according to a geology condition, forming pores in the stratum using a pore-forming machinery; (B) filling water sealing filler into the pore in sequence, attaching or pressing the filler into the stratum by a hammer, thus the water sealing filler is piled into the gap of the stratum or replaces the water seepage stratum, to form a water sealing pile around the pore; (C) redoing the steps (A) and (B) according to requirements, such that the neighboring water sealing piles are overlapped with each other or the water sealing pile is overlapped with other water sealing boundary to form a continuousenclosed water sealing belt to stop the groundwater from penetrating. The method of the invention has advantages of a simple construction, a reliable water sealing, and a low fabrication cost; it issuitable for various stratums, especially for a gravel layer, a fragmental stone layer and a pebble layer and has an obvious effect.

Description

Water-stopping method for civil engineering foundation technical field The invention relates to a water-stopping method for a civil engineering foundation, more specifically, it relates to a water-stopping method for a civil engineering foundation which is mainly used in the water-stopping construction of the side wall of the foundation pit or the construction of groundwater leakage plugging in the civil engineering. Background technique The current water-stopping methods for the side wall of the foundation pit in civil engineering mainly include the deep mixing pile method, the high-pressure jet method, the grouting method, the underground diaphragm wall method, and the steel sheet pile method. The deep mixing pile method is to mix and inject cement slurry or cement powder and soil to form piles while stirring, and to achieve the purpose of water stop by lapping piles. This method is simple in construction, widely used, and relatively expensive. But this method is only ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E02D19/12E02D5/34

Inventor 陆观宏马文旭

Owner 陆观宏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com