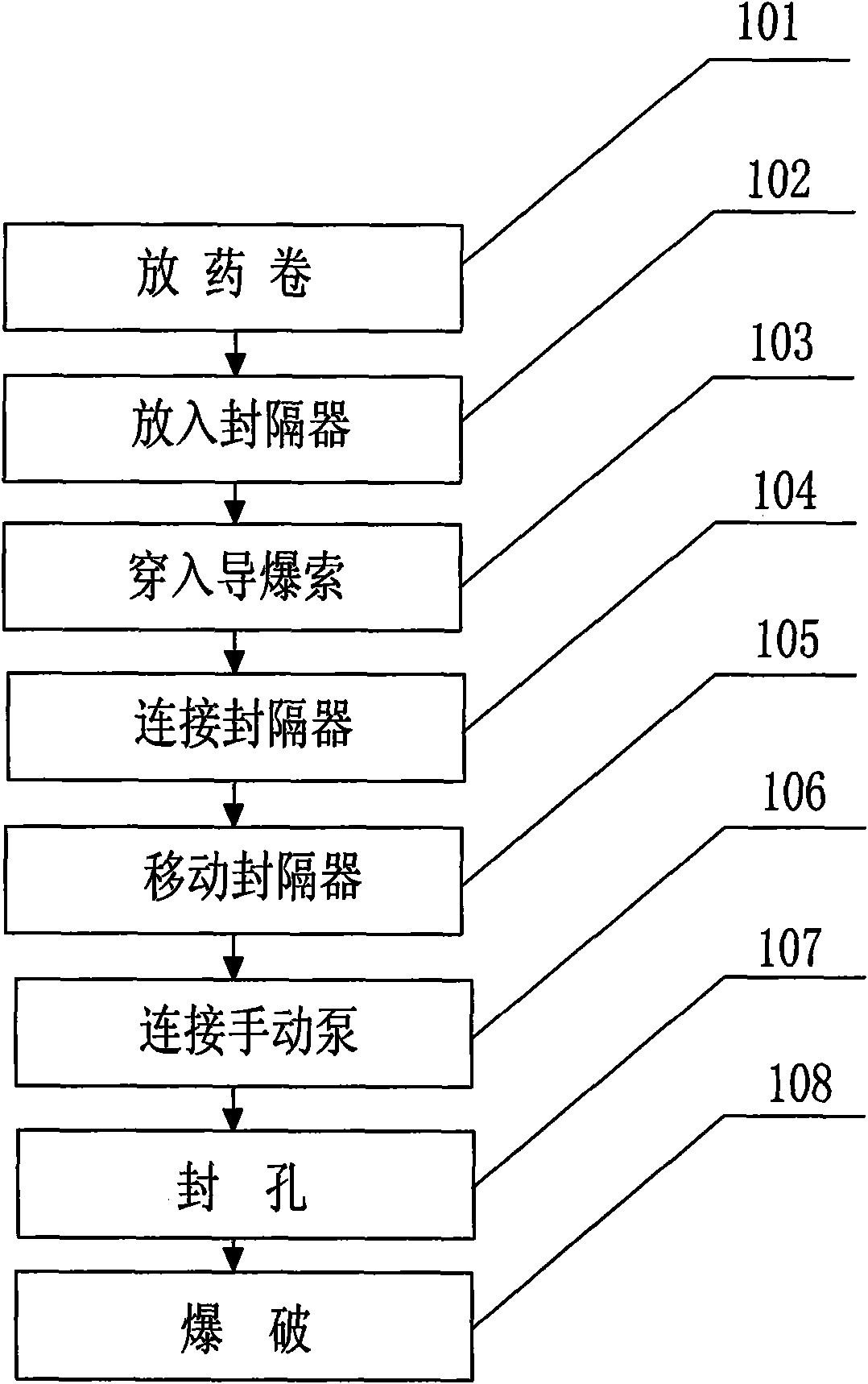

Hole sealing method for deep hole advanced loose blasting

A loose blasting and hole sealing technology, which is used in blasting, earthmoving, sealing/isolation, etc., can solve the problems of inability to guarantee the effect of hole sealing, inability to complete drilling and sealing, complicated process, etc., and achieve hole sealing. Good effect, improved sealing speed, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

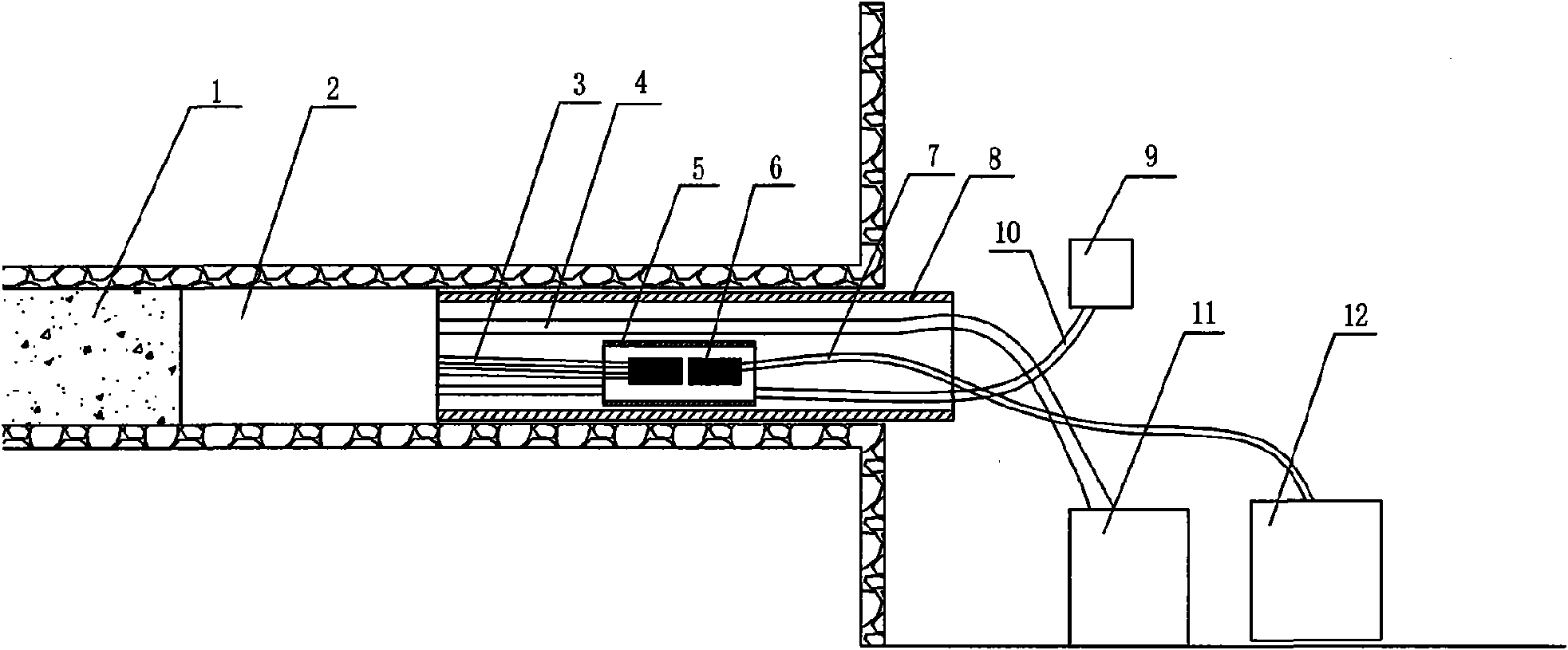

[0023] In order to make the general technology in the art can clearly understand the technical scheme of the present invention, now in conjunction with accompanying drawing, the present invention is described in further detail:

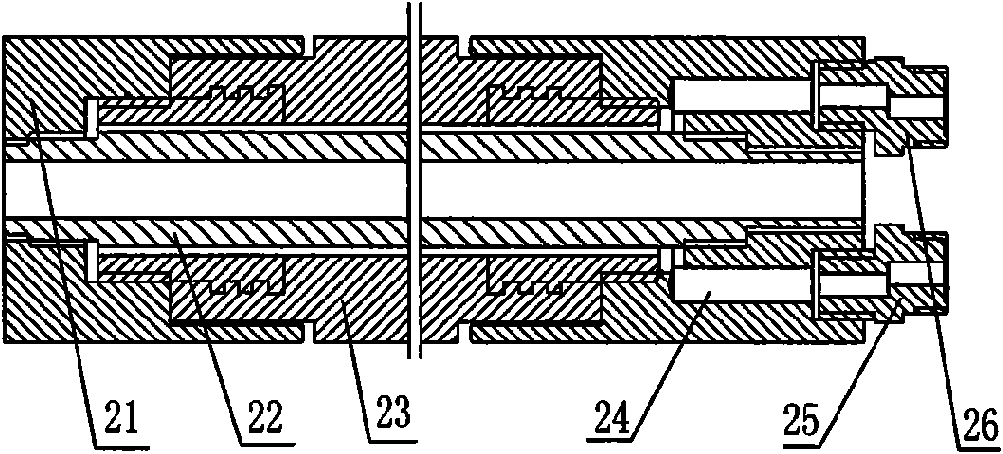

[0024] The present invention relates to the following devices: as figure 1 and figure 2 As shown, it includes: a cylindrical connecting rod 8 adapted to the borehole diameter, the cylindrical connecting rod 8 is hollow, the first high-pressure water pipe 4 is connected to the manual pump 11, the second high-pressure water pipe 10 is connected to the shut-off valve 9, and the detonator 6 Placed in the detonator barrel 5, the packer 2 is placed at the left end of the drug volume 1, and the packer 2 is connected with the first high-pressure water pipe 4 and the second high-pressure water pipe 10, wherein the packer 2 is composed of a front plug 21, a hollow pipe 22. The rubber tube 23, the rear plug 24, the left connector 25, and the right connector 26...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap