Boiler with automatic watering device

A technology for automatically adding water and boilers, which is applied in the field of boilers and can solve problems such as waste of steam sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described below in conjunction with the embodiments and the drawings.

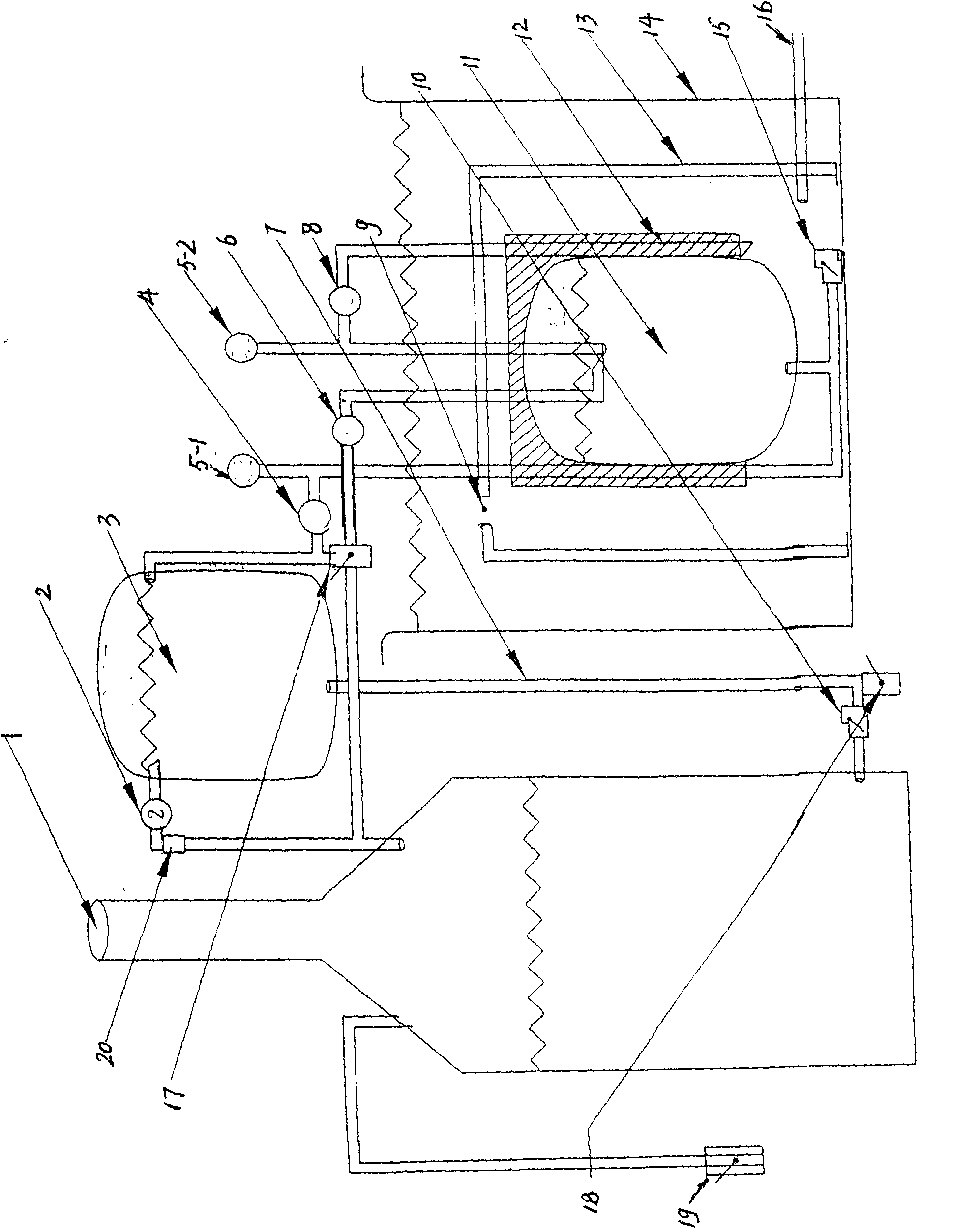

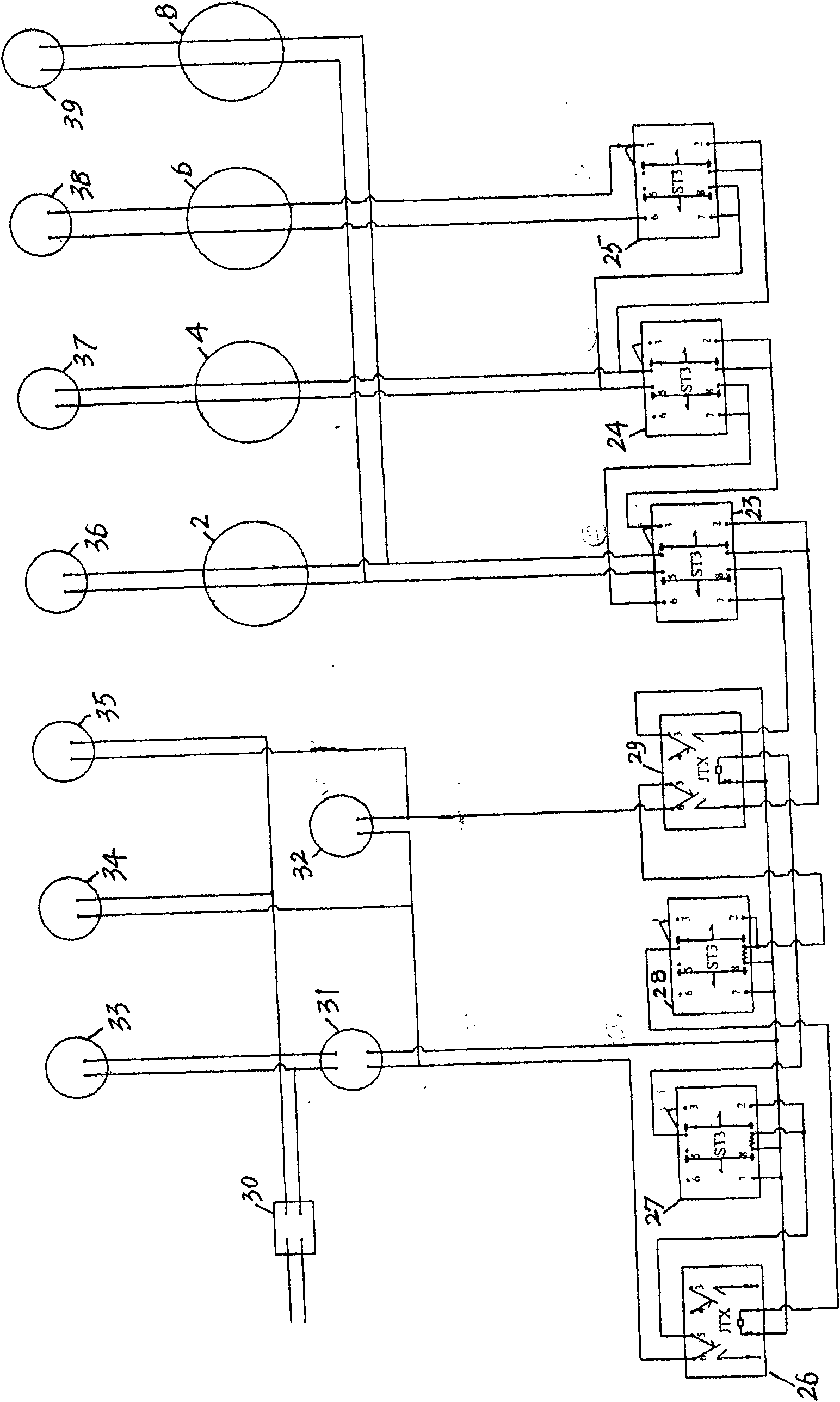

[0018] See figure 1 , A boiler with an automatic water filling device, which includes a boiler body 1 and an electric control box. The water filling tank 3 is arranged at a position above the water level line of the boiler body 1, the heat storage tank 13 is submerged in the water reserve tank 14, and the conversion tank 11 is placed in the heat storage tank 13, and the conversion tank 11 has a sealed heat preservation layer 12 outside the body. The capacity of the heat storage tank 13 is more than three times the capacity of the conversion tank 11. The water addition tank 3 passes through the booster valve 2 2 and the boiler body 1 is connected to the steam outlet, the water filling tank 3 is connected to the bottom of the conversion tank 11 through the conversion valve 4 and a pressure gauge 5-1 is installed on the connecting pipe, and the water filling tank drain valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com