Wind damage proof billboard frame

A technology for billboards and advertisements, applied to signs, signs, instruments, etc., which can solve the problems of high billboard maintenance costs, reduced wind area, increased material and construction costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

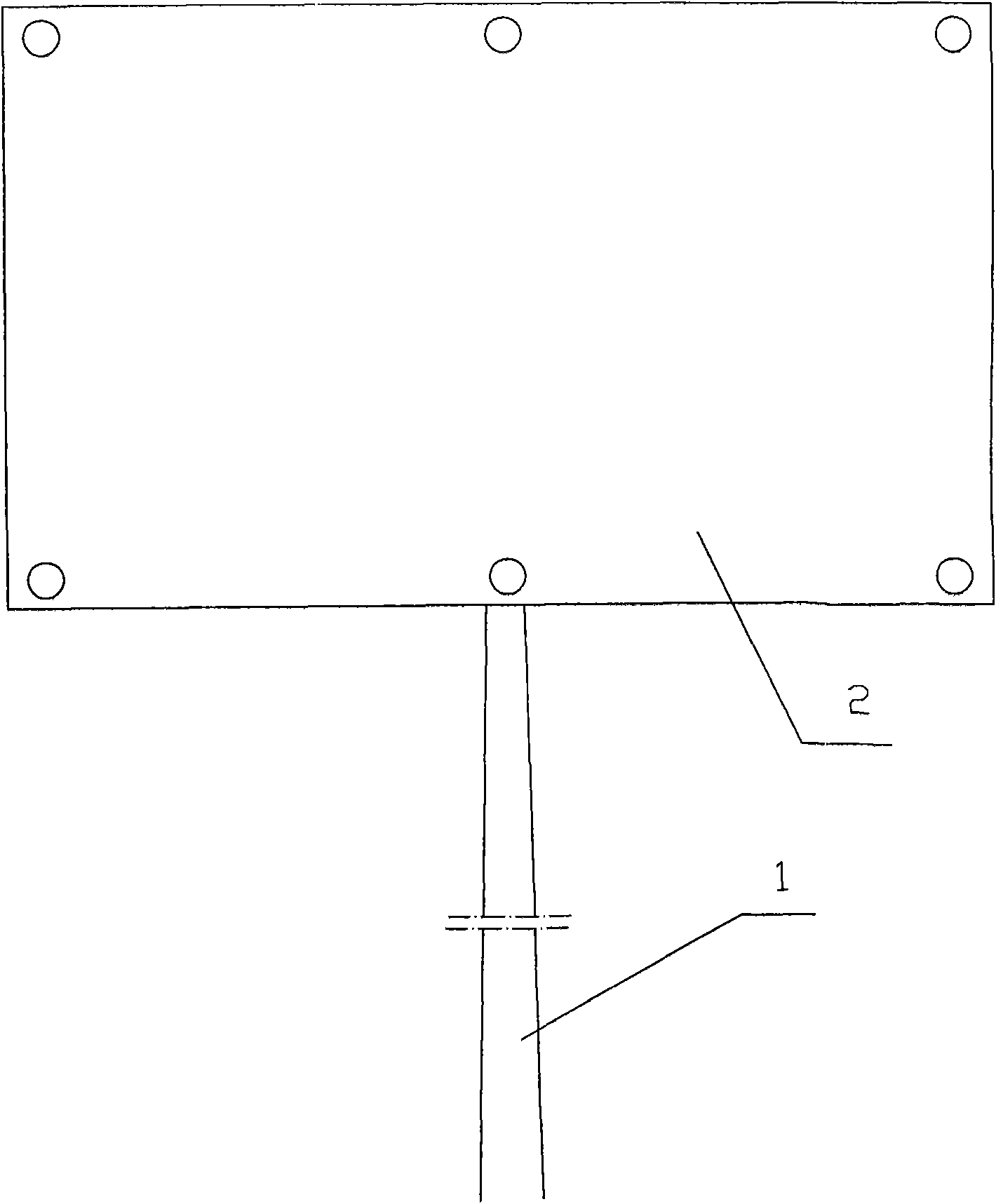

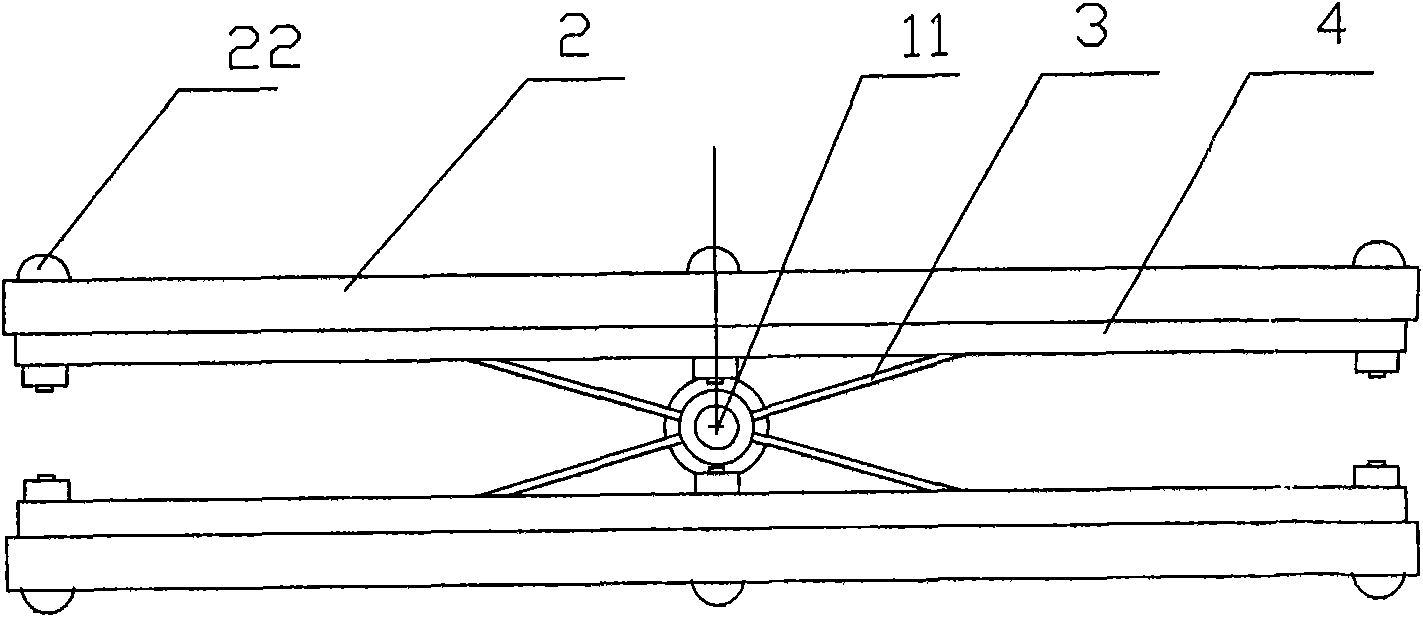

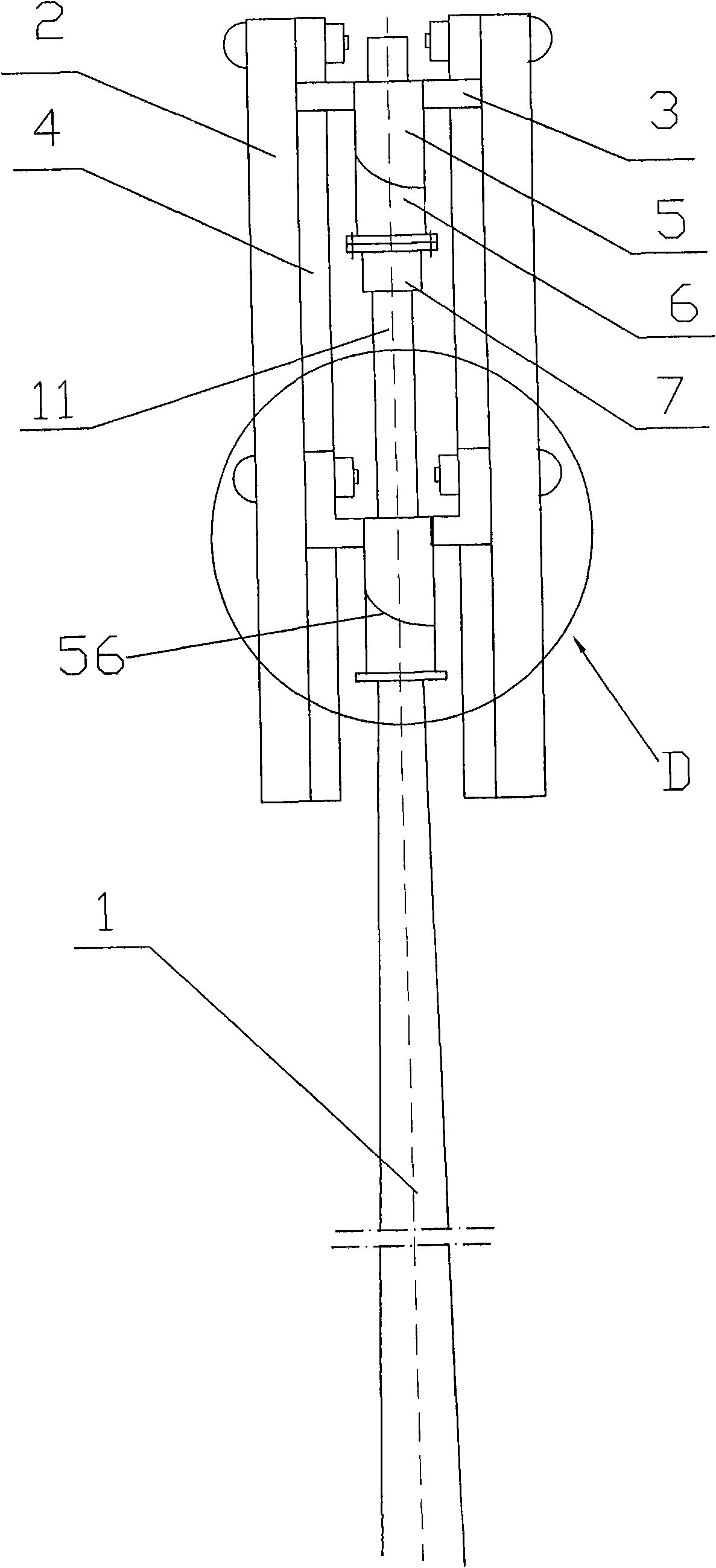

[0018] like figure 1 As shown, the billboard board 2 is installed on the upper end of a column 1. It can be installed symmetrically in a T shape as in this embodiment, or it can be installed asymmetrically in a Γ shape. The billboard board 2 can be installed symmetrically on both sides as in this embodiment, or it can be installed single surface installation. The rectangular frame 4 that billboard drawing board and angle steel are welded into is covered and fixed by screw 22. Column 1 is made of steel pipes, the diameter is small at the top and large at the bottom, wherein the upper end is a section of equal-diameter cylinder 11, which can reduce the production cost, such as image 3 shown. The circular tube-shaped swivel body that is sleeved on the equal-diameter cylinder 11 is fixedly connected with the billboard frame 4 through the diagonal struts 3 .

[0019] This design is as Figure 3 ~ Figure 5 As shown, a pair of circular tube-shaped swivels 5 and circular tube-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com