A rotating electric component

A technology of electrical components and rotary type, which is applied in the direction of electrical components, circuits, electric switches, etc., and can solve problems such as damage operability, uneven torque, thermal deformation of rotating parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

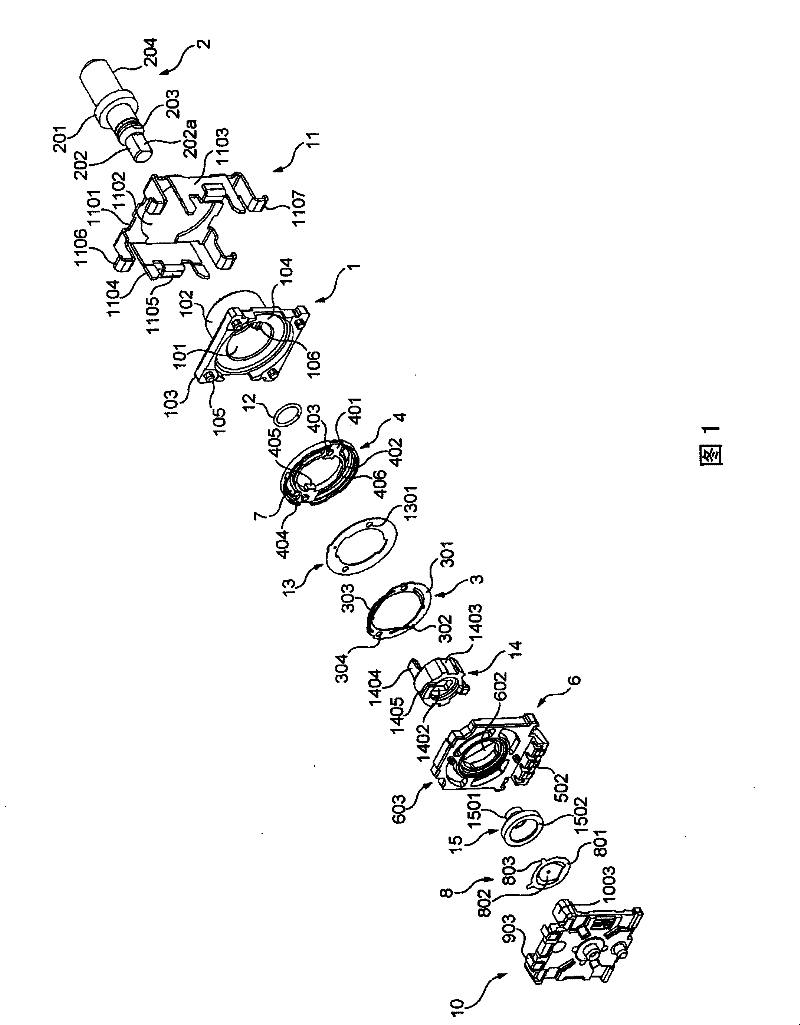

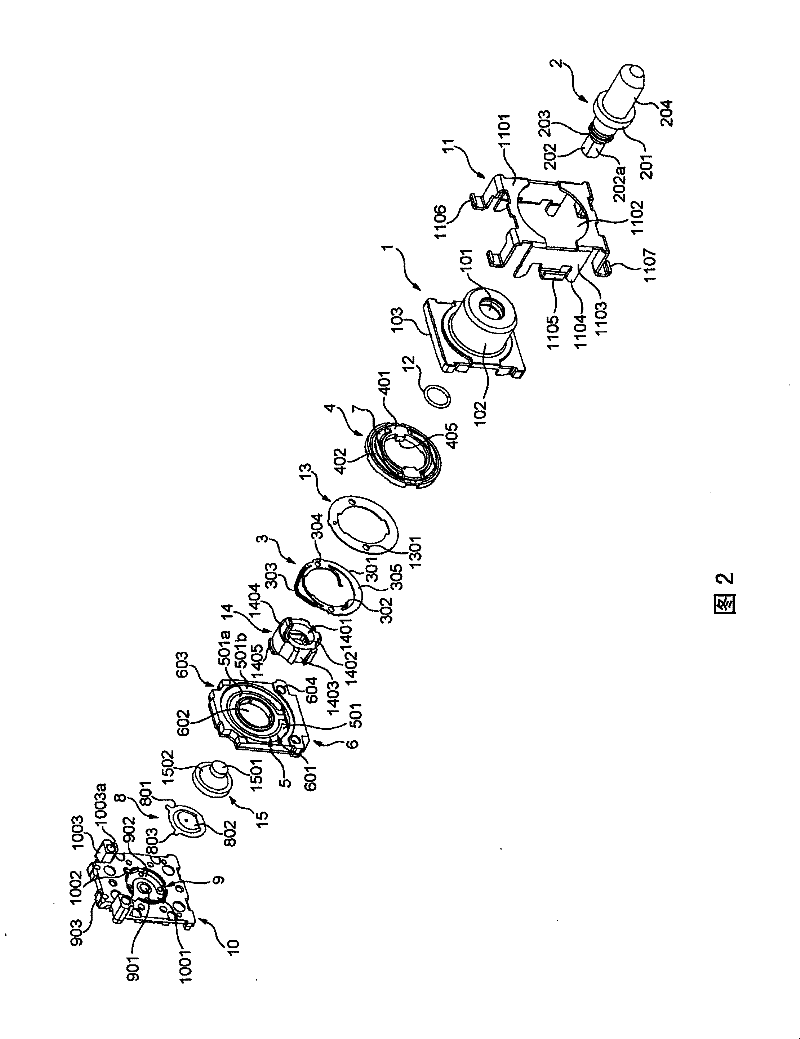

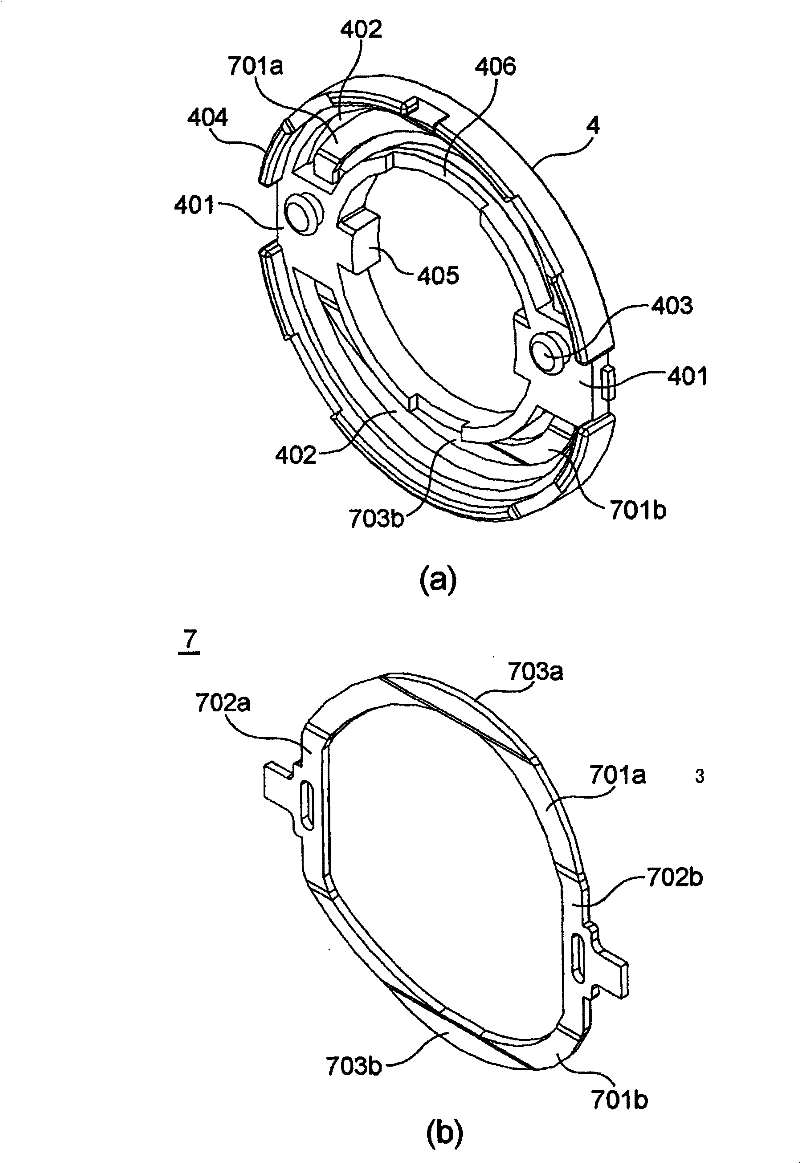

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 as well as figure 2 It is an exploded perspective view of a rotary electric component according to an embodiment of the present invention. figure 1 as well as figure 2 It is an exploded perspective view of a rotary electric component shown from different directions. Also, in the following, for convenience, the figure 1 The left side shown is called "the rear side of the rotary electrical component" or simply "the rear side", and the right side shown in the figure is called the "front side of the rotary electrical component" or simply "the front side". side".

[0026] Such as figure 1 as well as figure 2 As shown, the rotary electric component of this embodiment generally includes a metal bearing member 1 having a through hole 101, a rotating shaft 2 as a shaft member rotatably inserted through the through hole 101 of the bearing member 1, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com