Tool rest device for fully-automatic chamfering machine

A chamfering machine, fully automatic technology, used in milling machine equipment details, metal processing equipment, milling machine equipment, etc., can solve the problems of labor and time, bolts and scraps cannot be separated by themselves, etc., to reduce downtime, speed, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

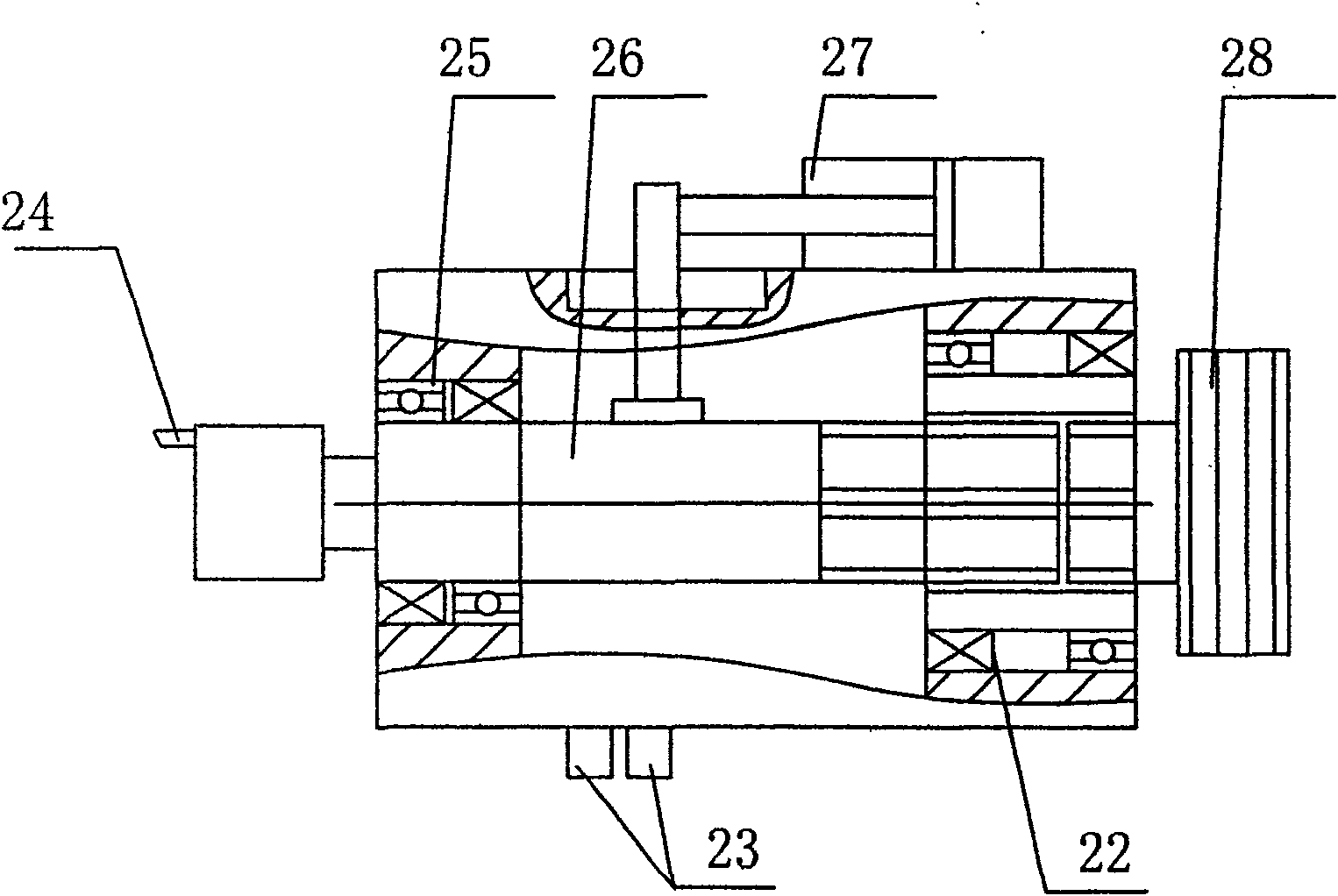

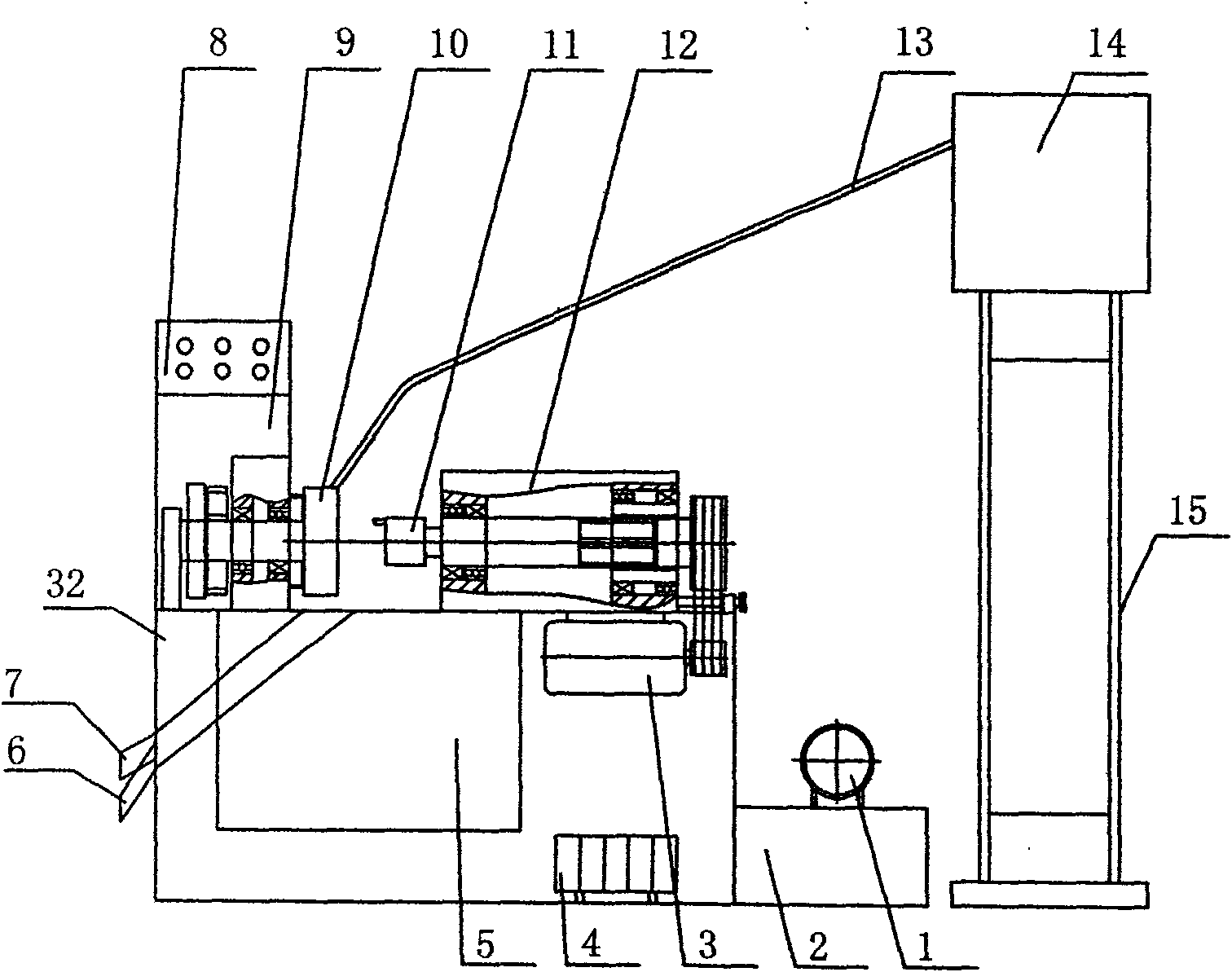

[0012] As shown in the figure, it includes a motor 3, a spline shaft 26, a pulley 28, a tool rest control box 12, a bearing, a hydraulic cylinder 27, a tool rest 11, a cutter head 24, a travel switch 23 and an electric control device, and the motor 3 main shaft passes through Belt pulley 28, belt connection spline shaft 26, spline shaft adopts bearing to be installed in the knife rest control box 12, the shaft end of spline shaft 26 is connected with knife rest 11, and the knife rest is movably connected with cutter head 24, and spline shaft cooperates to connect hydraulic pressure Cylinder 27.

[0013] The cutter head is an adjustable cutter head. The electrical control device is mainly composed of a main power supply, an operating part, a program running part, an action execution part, and an operation signal feedback part. The operating signal is ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com