Fully automatic bolt chamfering machine

A chamfering machine, fully automatic technology, applied in the details of milling machine equipment, metal processing equipment, milling machine equipment, etc., can solve the problems that bolts and scraps cannot be separated by themselves, labor and time-consuming, etc., achieve high speed, reduce costs, and improve processing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

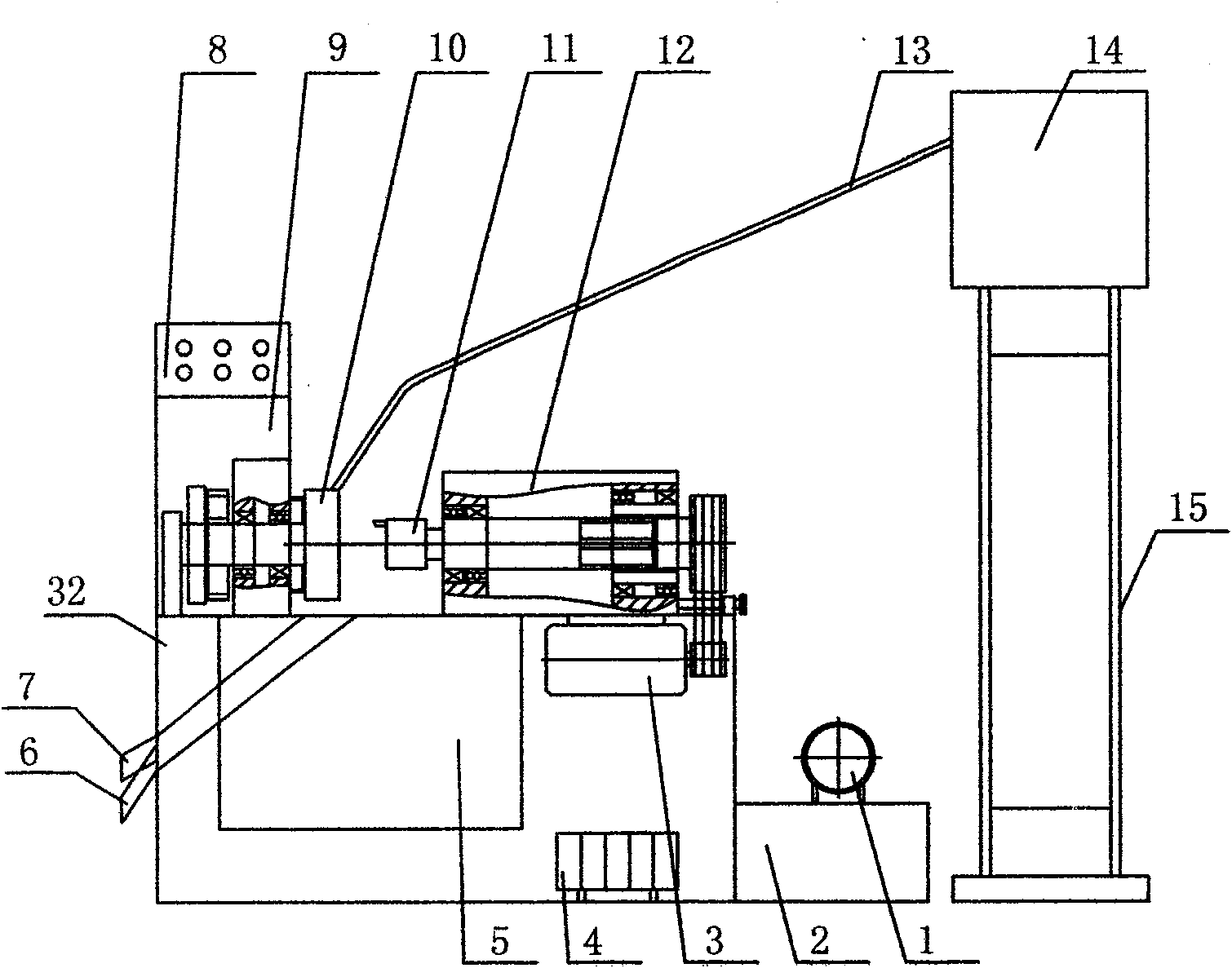

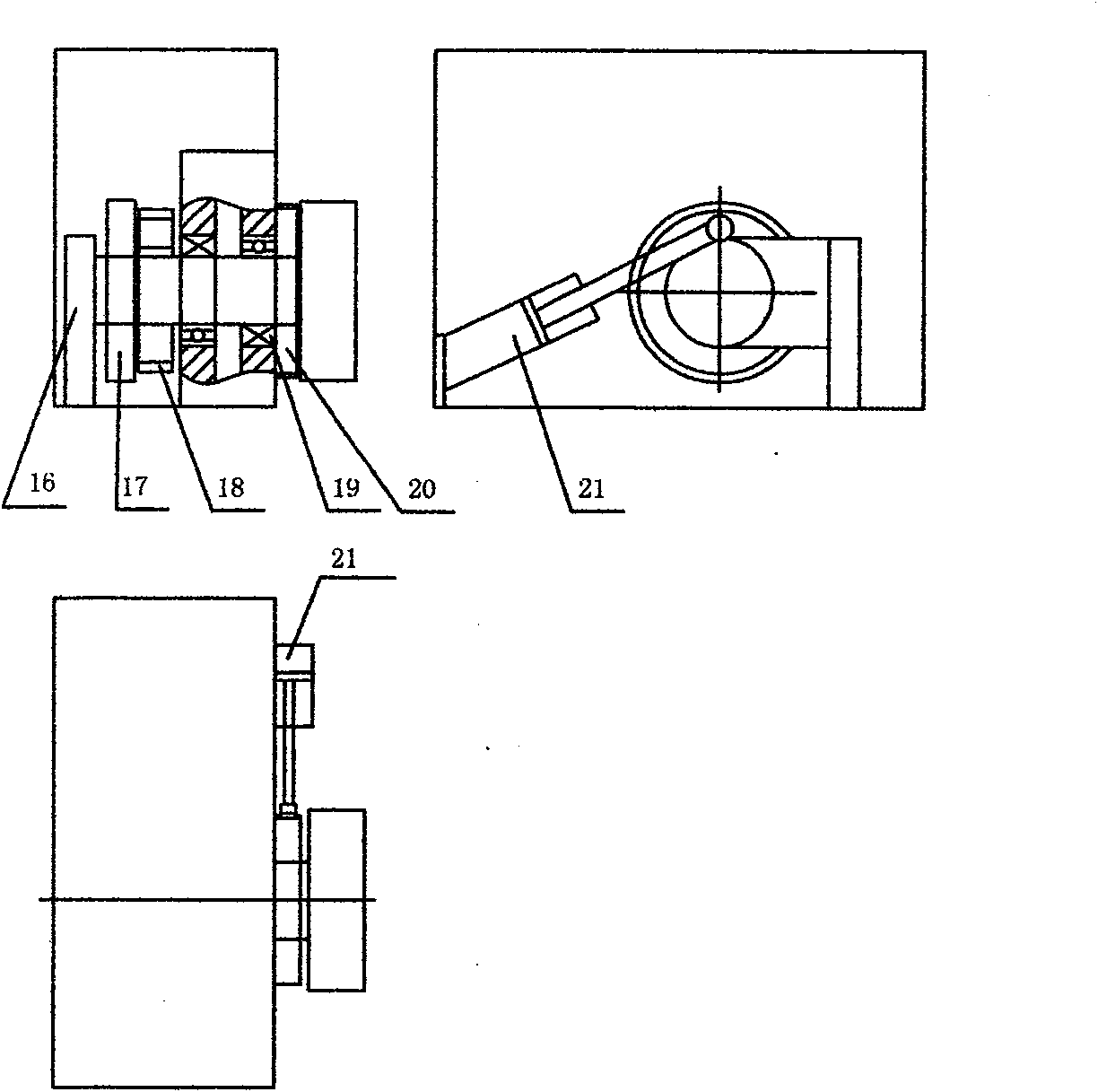

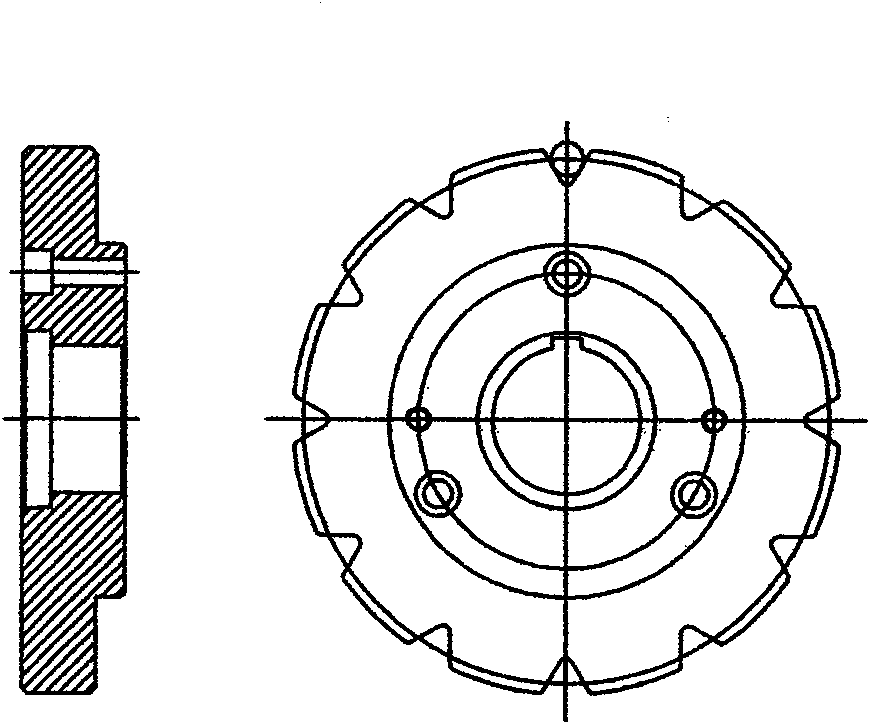

[0019] As shown in the figure, a fully automatic bolt chamfering machine includes a feeding mechanism, a clamping mechanism, a tool rest mechanism machine table, a blanking mechanism and an electrical control system. Plate 14 and slide rail 13, vibrating plate 14 is installed on the upper end of feeding bracket 15, and the feeding outlet end of the vibrating plate is connected with the feeding inlet end of slide rail 13, and the described slide rail is inclined downward at a certain angle in the horizontal direction, generally 45° degrees or so. The slide rail feeding outlet of the feeding mechanism is connected to the chuck 10 inlet of the clamping mechanism, and the clamping mechanism includes a friction belt 16, a drive plate 17, an indexing plate 18, a bearing 19, a chuck seat 20, a chuck Disc 10 and hydraulic cylinder 21, the hydraulic cylinder mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com