Method for testing laser metal direct forming based on self-healing mechanism

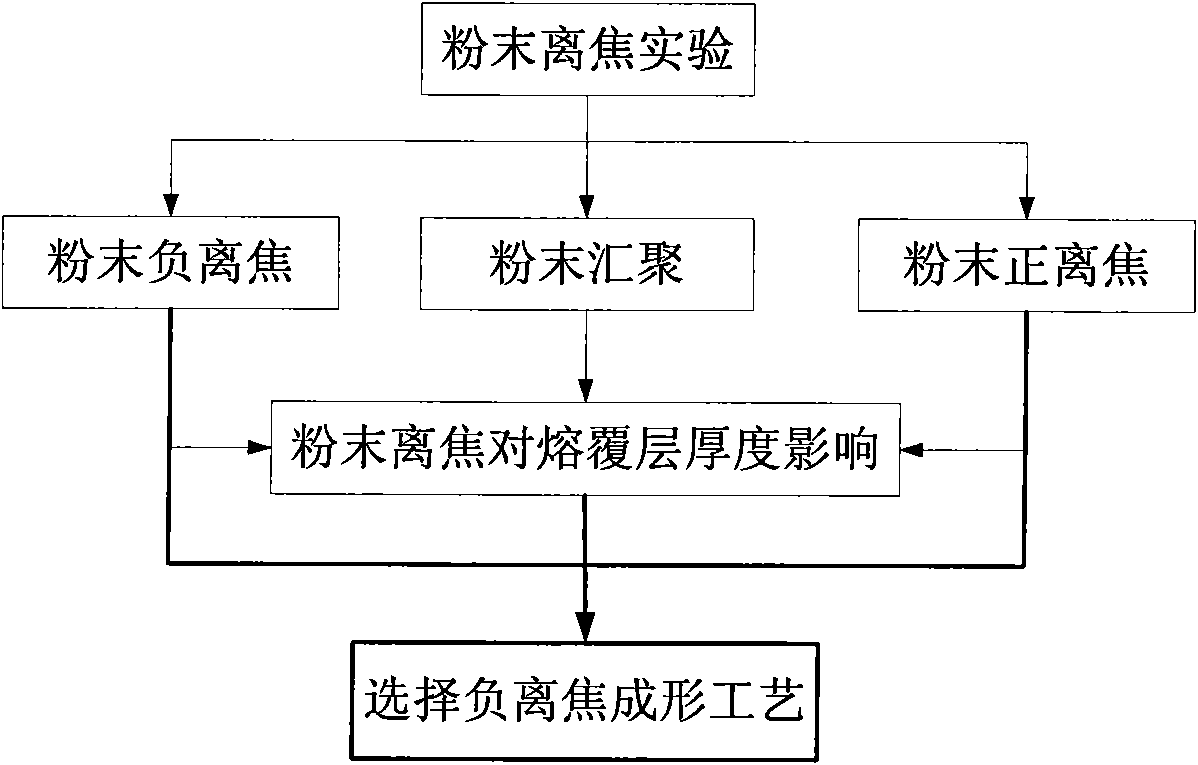

An experimental method, metal forming technology, applied in the field of laser repair, can solve the problems of unpredictable height of formed parts, uneven forming surface, complex forming process conditions, etc., to eliminate uneven forming surface, stabilize cladding forming, and promote development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

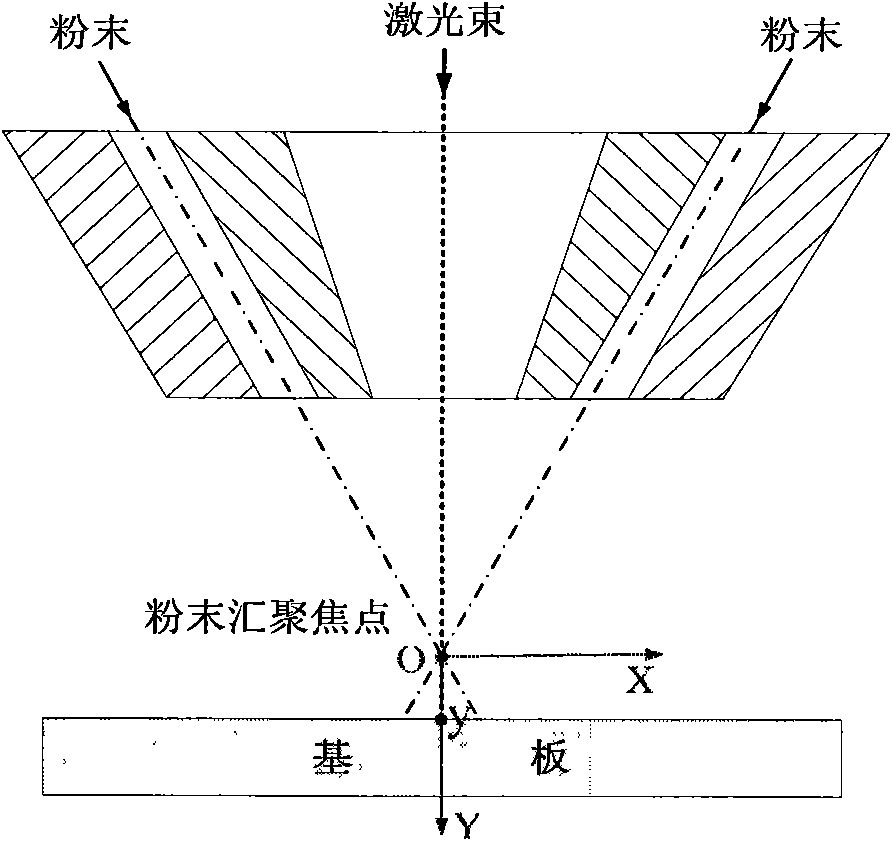

Method used

Image

Examples

Embodiment 1

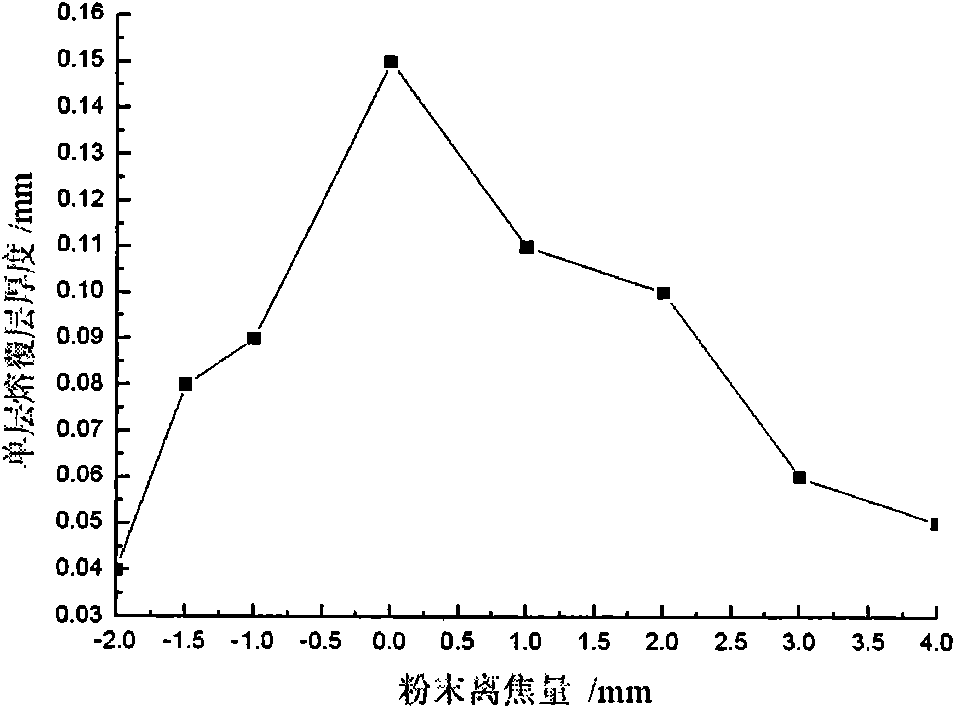

[0026] Using powder convergence or positive defocusing process for single-pass laser metal forming, the uneven surface of the parts is accumulated, such as Figure 5 shown.

Embodiment 2

[0028] Using powder negative defocusing process for single-pass laser metal forming, and Figure 5 Compared with the forming quality, the forming surface of the stacked thin-walled parts is very smooth, such as Figure 6 shown.

Embodiment 3

[0030] Negative powder defocus is used for laser metal direct forming of complex parts; y=-1.5mm, Z-axis increment is 0.08mm, and the number of stacked layers is 100. When the powder is negative defocus, laser metal direct forming has a self-healing effect, which can Ensure the stable progress of the trip.

[0031] Such as Figure 7 As shown, when the negative defocus of the powder is y=-1.5mm, the Z-axis increment is 0.08mm, the number of stacked layers is 530, and the height of the part is 42.6±0.03mm. Experiments have obtained thin-walled parts, and their forming surfaces are quite flat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com