Welding device for gantry-shaped steel of forklift

A forklift mast and welding device technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency, easy welding deformation, difficult welding positioning, etc., and achieve low welding efficiency, difficult welding positioning, The effect of welding is not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Attached below Figure 1 to Figure 4 The present invention is described in further detail with embodiment:

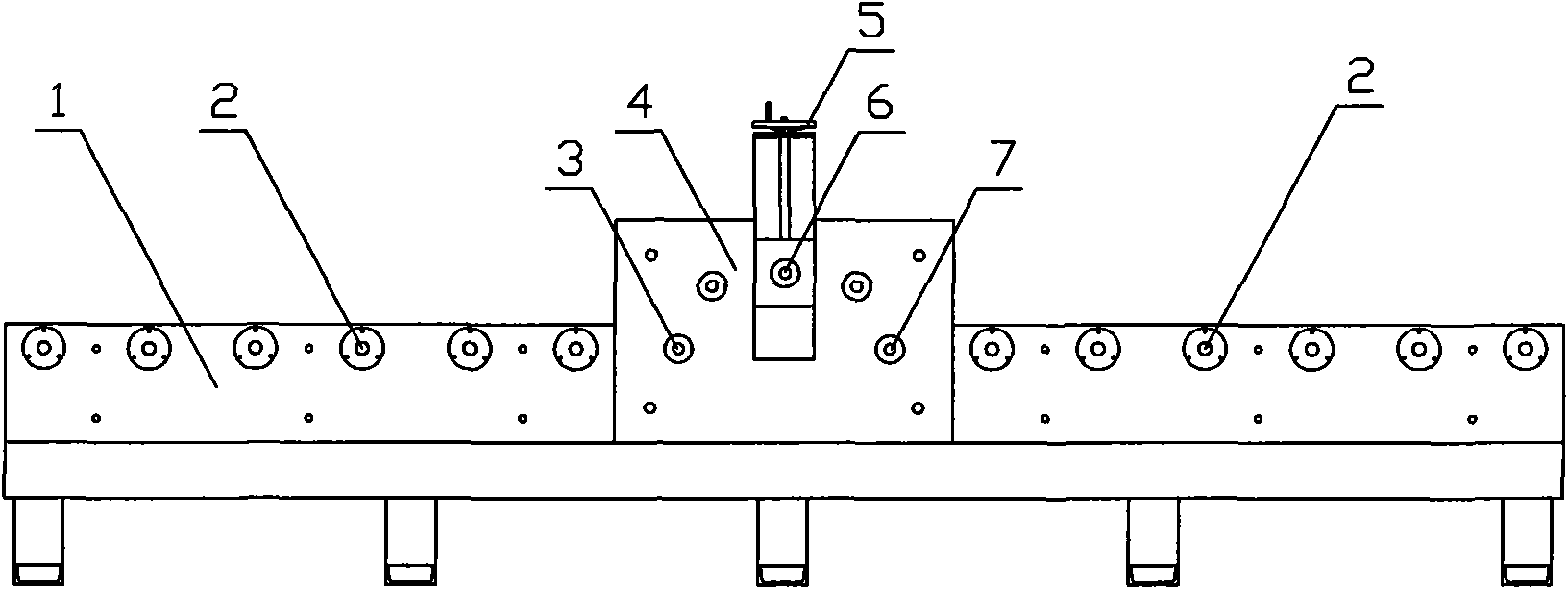

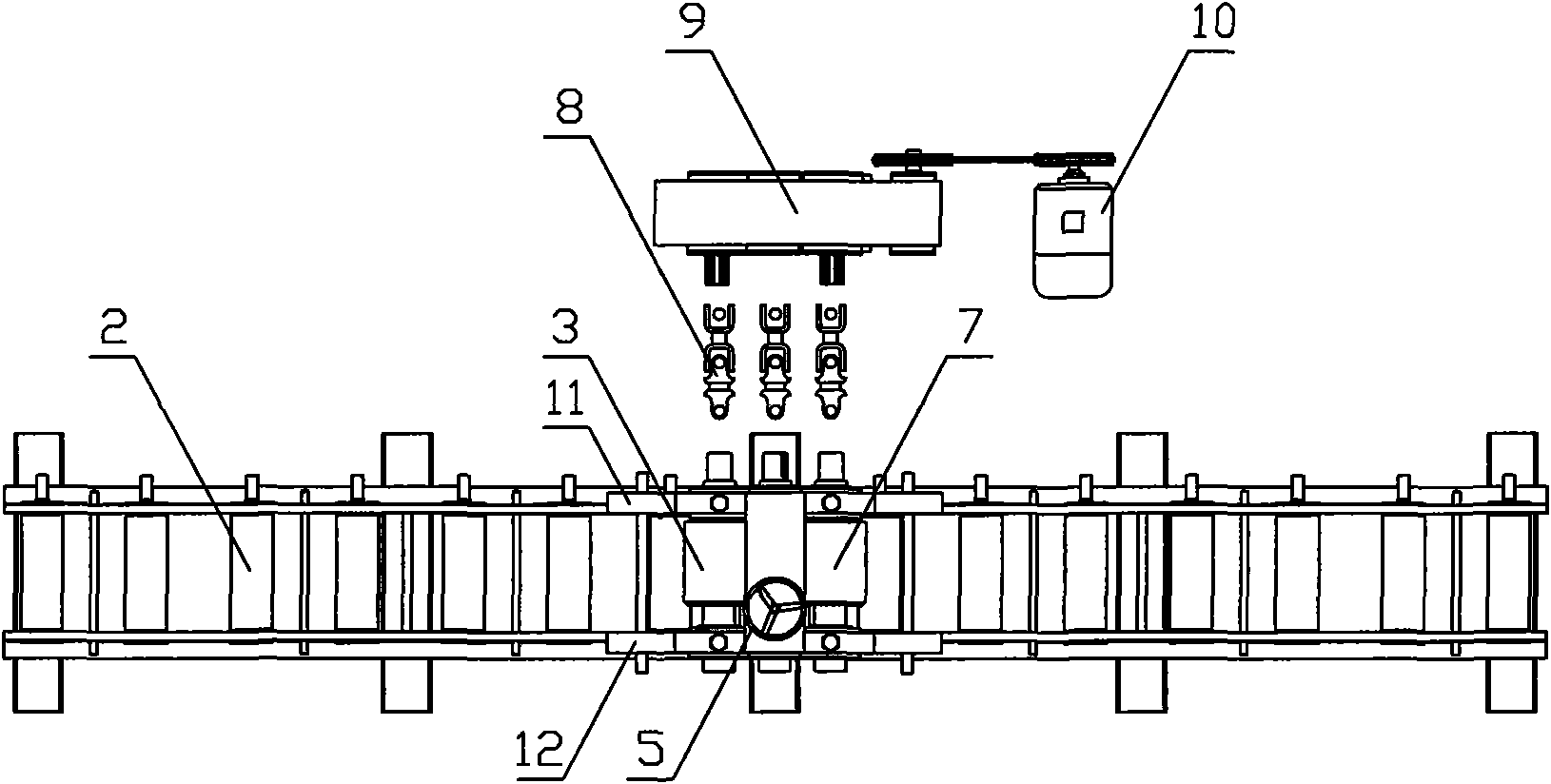

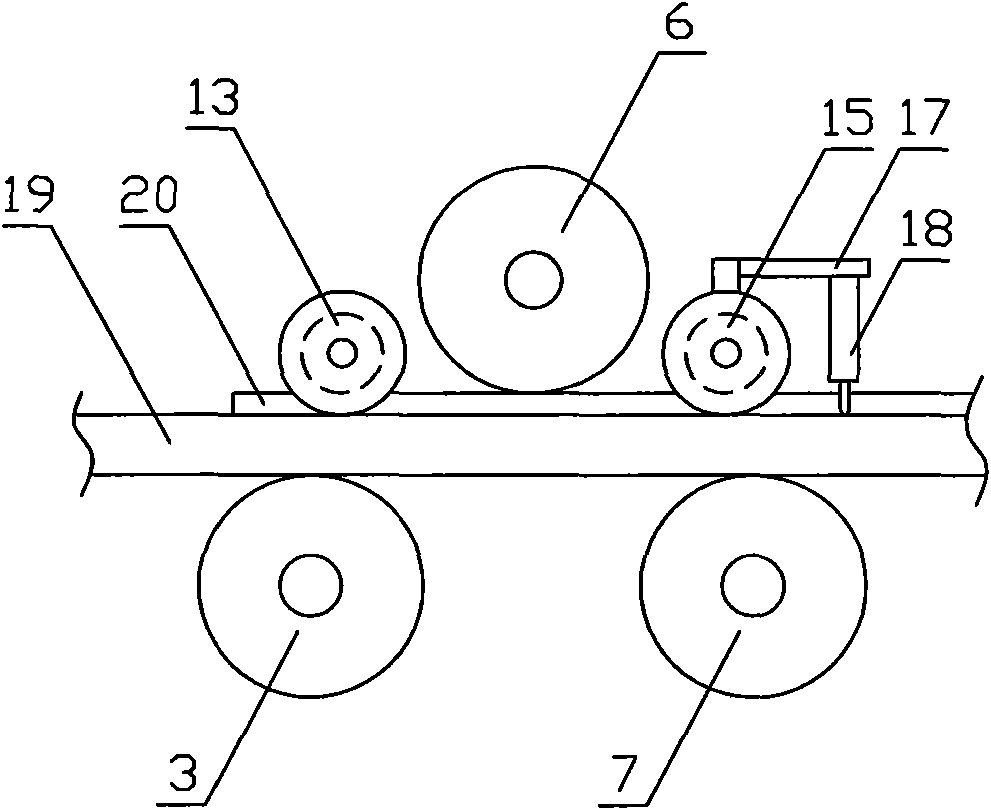

[0022] Embodiment forklift mast section steel welding device, as Figure 1 to Figure 4 As shown, it includes a welding station 4 and a welding torch 18 installed on the welding station 4. The welding station 4 is arranged on the material guiding platform 1. The material guiding platform 1 is provided with several guide wheels 2 from left to right. The welding platform 4 includes a front The supporting plate 12, the rear supporting plate 11, and the upper moving wheel 6, the left moving wheel 3 and the right moving wheel 7 erected between the front supporting plate 12 and the rear supporting plate 11; the upper moving wheel 6, the left moving wheel 3 and the right moving wheel 7 pass through the universal Joint 8 is connected with gear case 9, and gear case 9 is connected with motor 10, and left moving wheel 3 and right moving wheel 7 all link to each other with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com