Pressing mechanism used for minibus welding

A technology of a pressing mechanism and a van, which is applied in the field of tooling and fixtures, can solve the problems of reduced work efficiency in the third process, inconvenient operation by staff, and inability to achieve consistent production, and is beneficial to identification and operation, and has good reliability. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

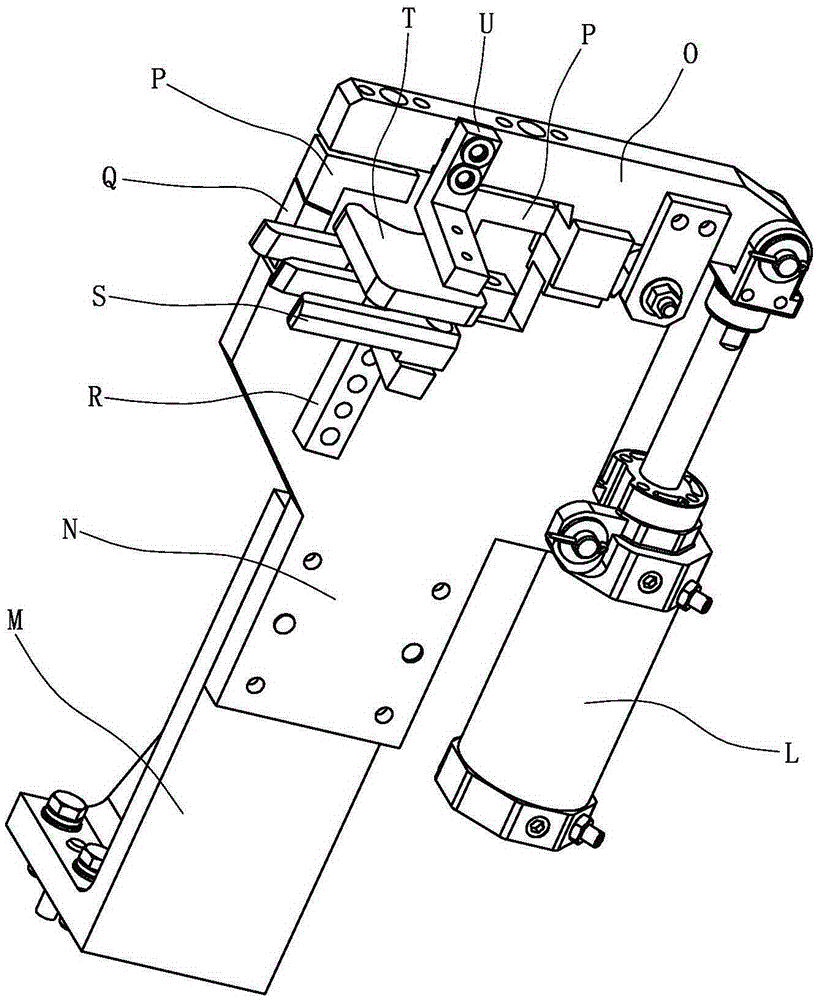

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

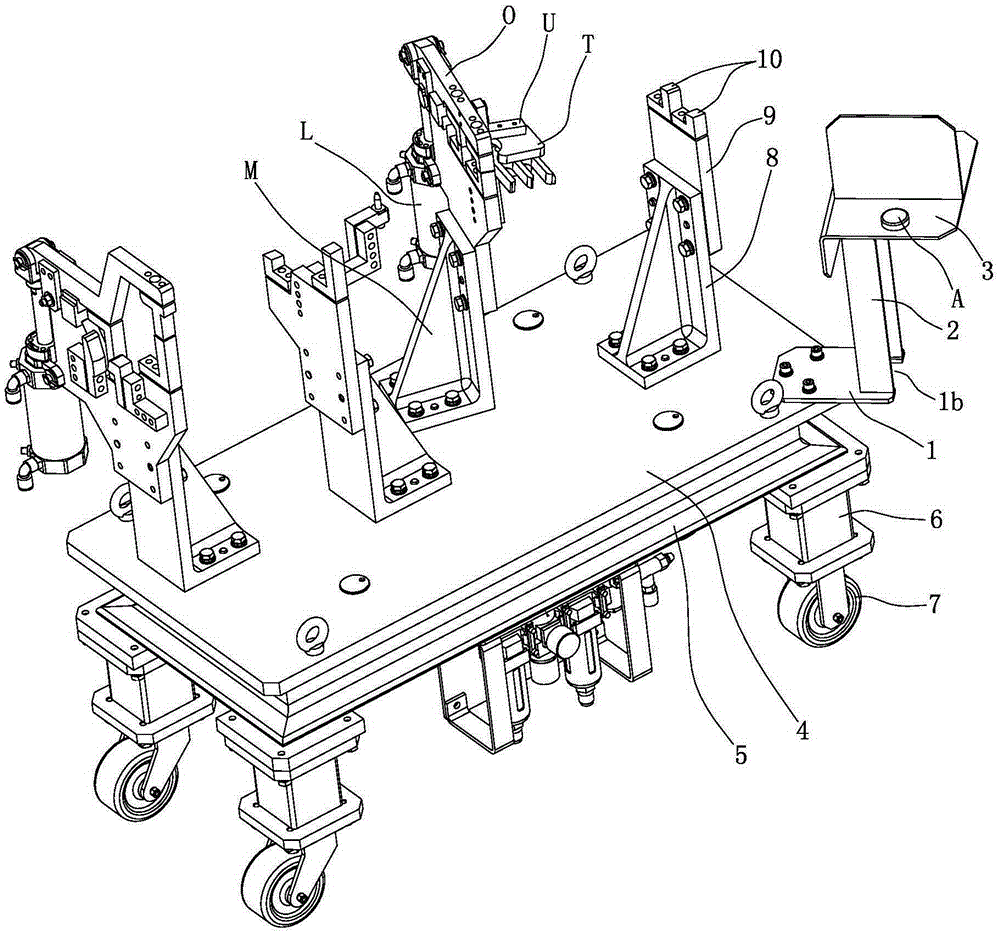

[0021] Such as figure 1 , figure 2 As shown, the platform 4 is rectangular, supported by the bottom frame 5, the bottom frame 5 is a square frame structure, and the bottom frame 5 and the platform 4 are welded and fixed. All be provided with booster seat 6 at four corners of base frame 5 bottoms, the top surface of booster base 6 fixedly supports the bottom surface of bottom frame 5 corresponding corners, and roller 7 is installed below each booster base 6, and the bottom surface of base frame 5 below Two of the four rollers 7 are universal wheels, and the other two are directional wheels, so that the whole device moves and is positioned at the desired position.

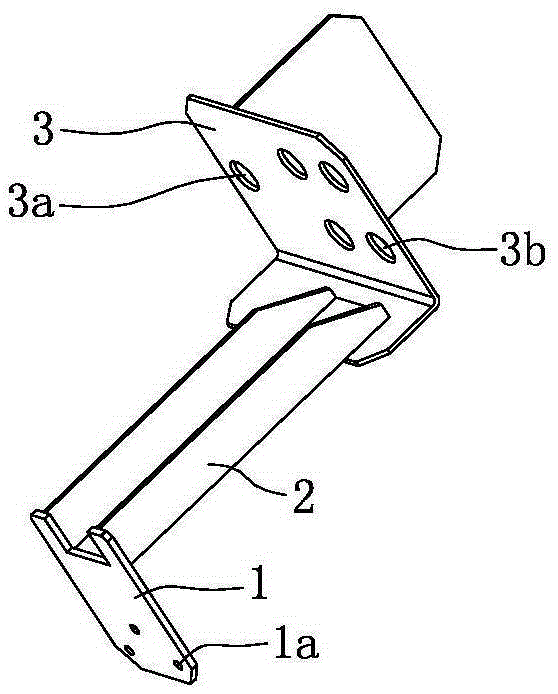

[0022] Such as figure 1 , figure 2 As shown, an operation box is provided at a corner of the top surface of the platform 4 , and the operation box has a bottom plate 1 , which is formed by sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com