Refrigerator evaporating dish

A technology for evaporating pans and refrigerators, which is applied in the field of evaporating pans for air-cooled refrigerators, which can solve the problems of inconvenient installation, poor evaporation capacity, and large space occupation, and achieve the effects of easy cleaning and enhanced ability to evaporate condensed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

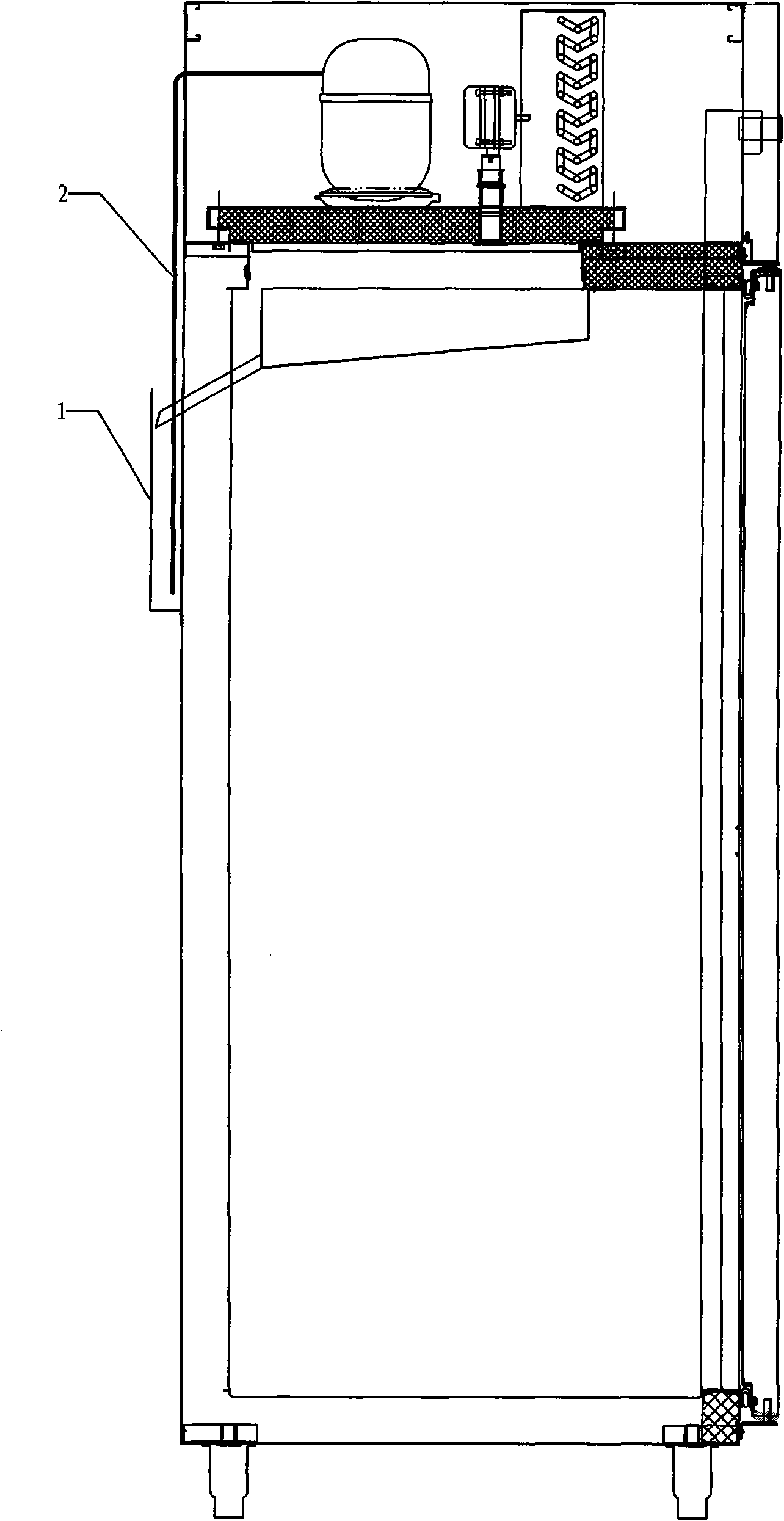

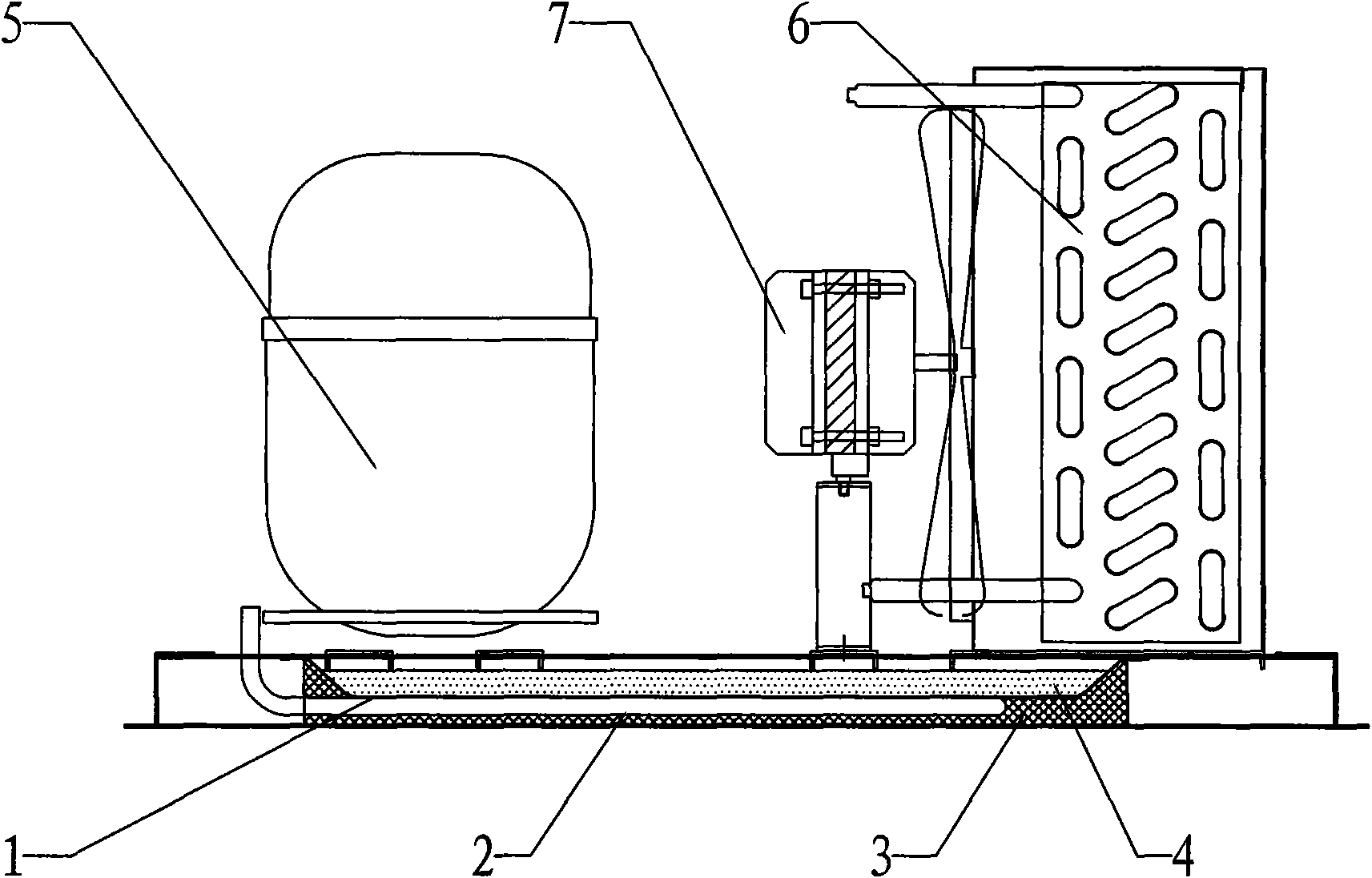

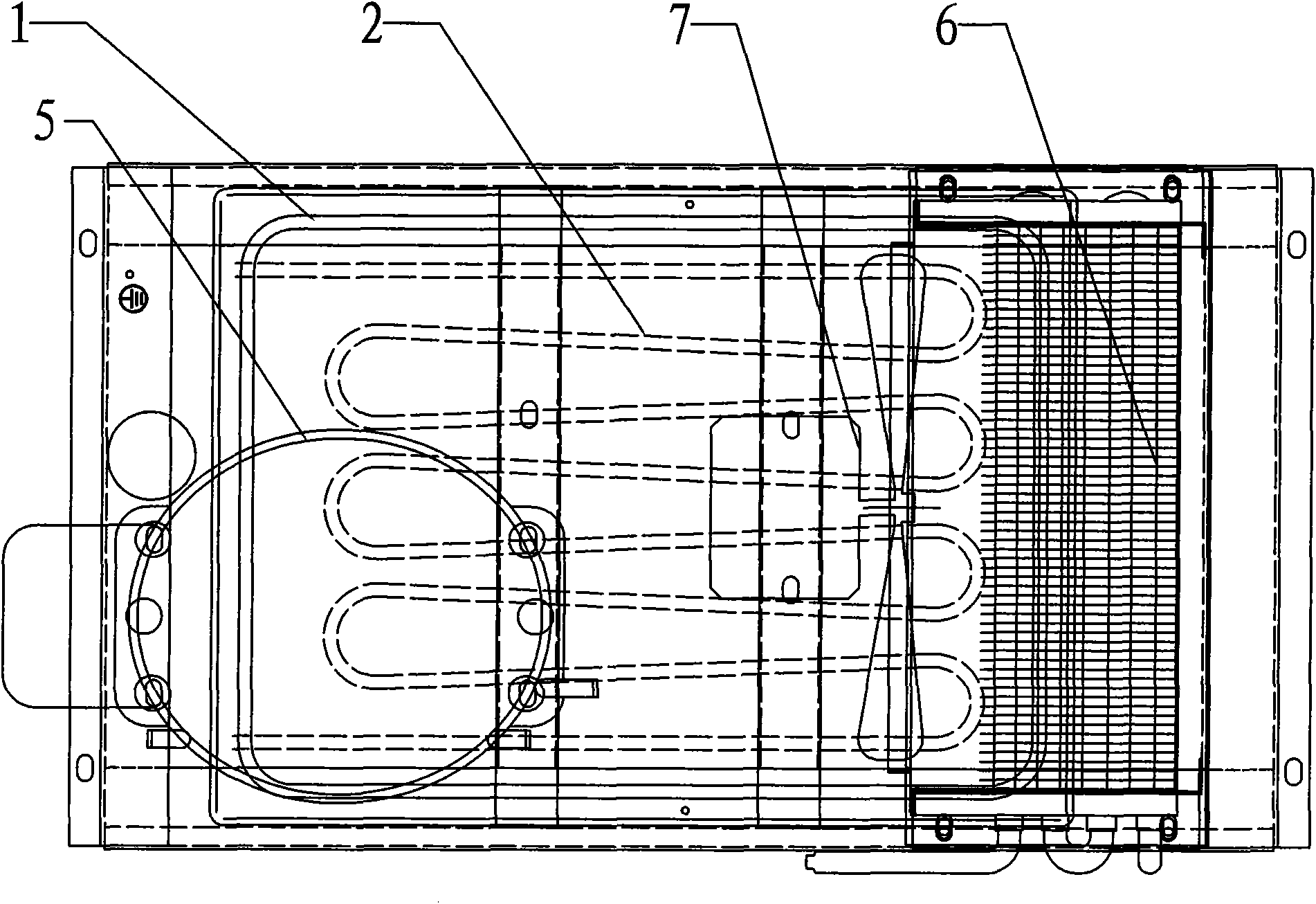

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] refer to Figure 2-Figure 4 , a refrigerator evaporating dish, comprising a condensed water sump 1 and a compressor drain pipe 2, the condensed water sump 1 is a stainless steel sump, the refrigerator evaporating dish also includes an insulating layer 3, and the insulating layer 3 covers the The outer wall of the condensed water collection tank 1, the compressor drain pipe 2 is arranged between the thermal insulation layer 3 and the outer wall.

[0021] The compressor drain pipe 2 is in close contact with the outer wall; the way of close contact is: the contact surface between the compressor drain pipe and the outer wall is coated with a layer of heat-conducting material. Alternatively, the compressor drain pipe and the outer wall are brazed with a heat-conducting material. Alternatively, aluminum foil tape is used to bond the compressor drain pipe 2 and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com