Process cartridge detachably mountable to image forming apparatus

A technology of an imaging device and a processing cartridge, which is applied in the field of processing cartridges and can solve the problems of accuracy dependence and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

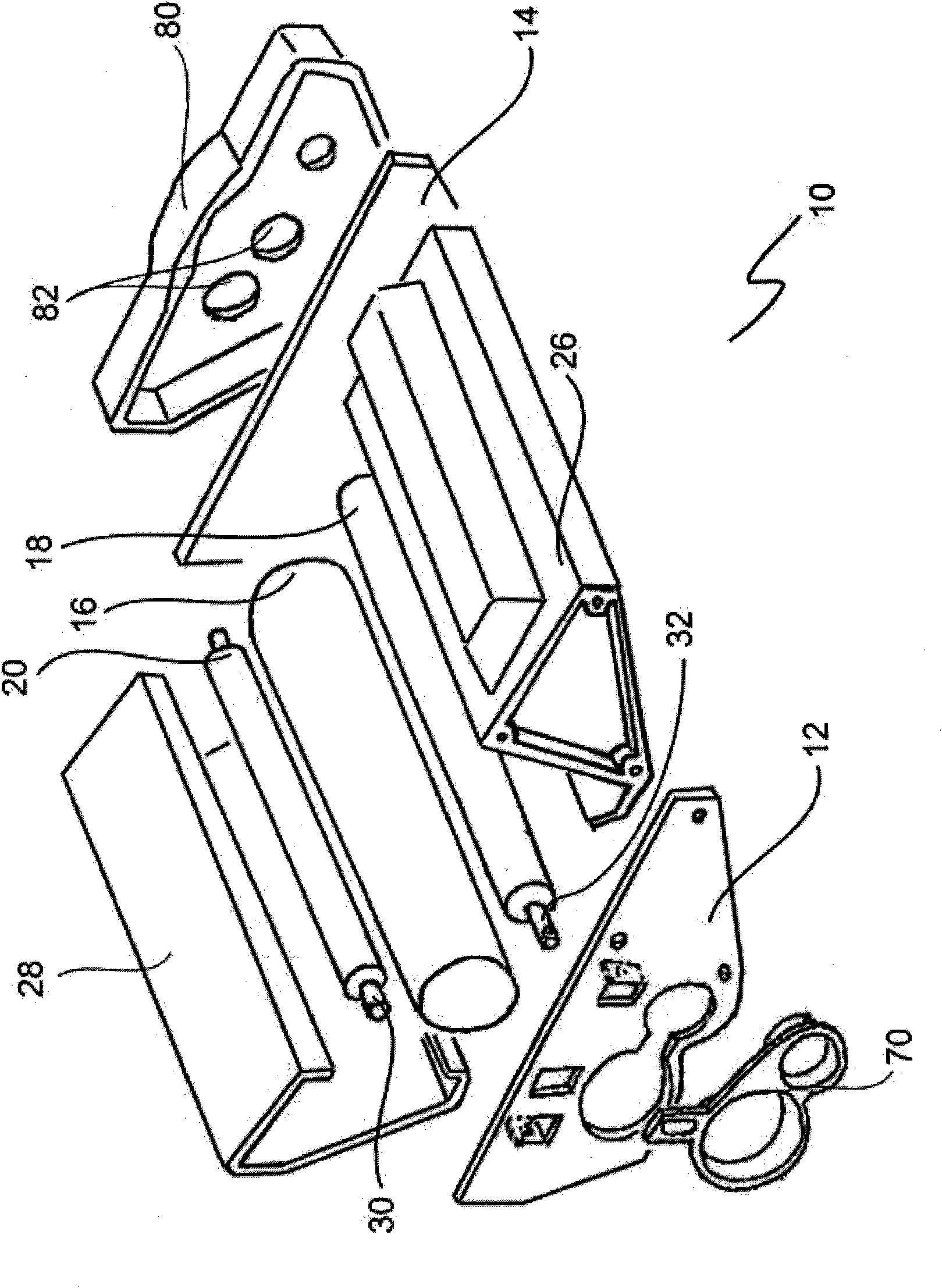

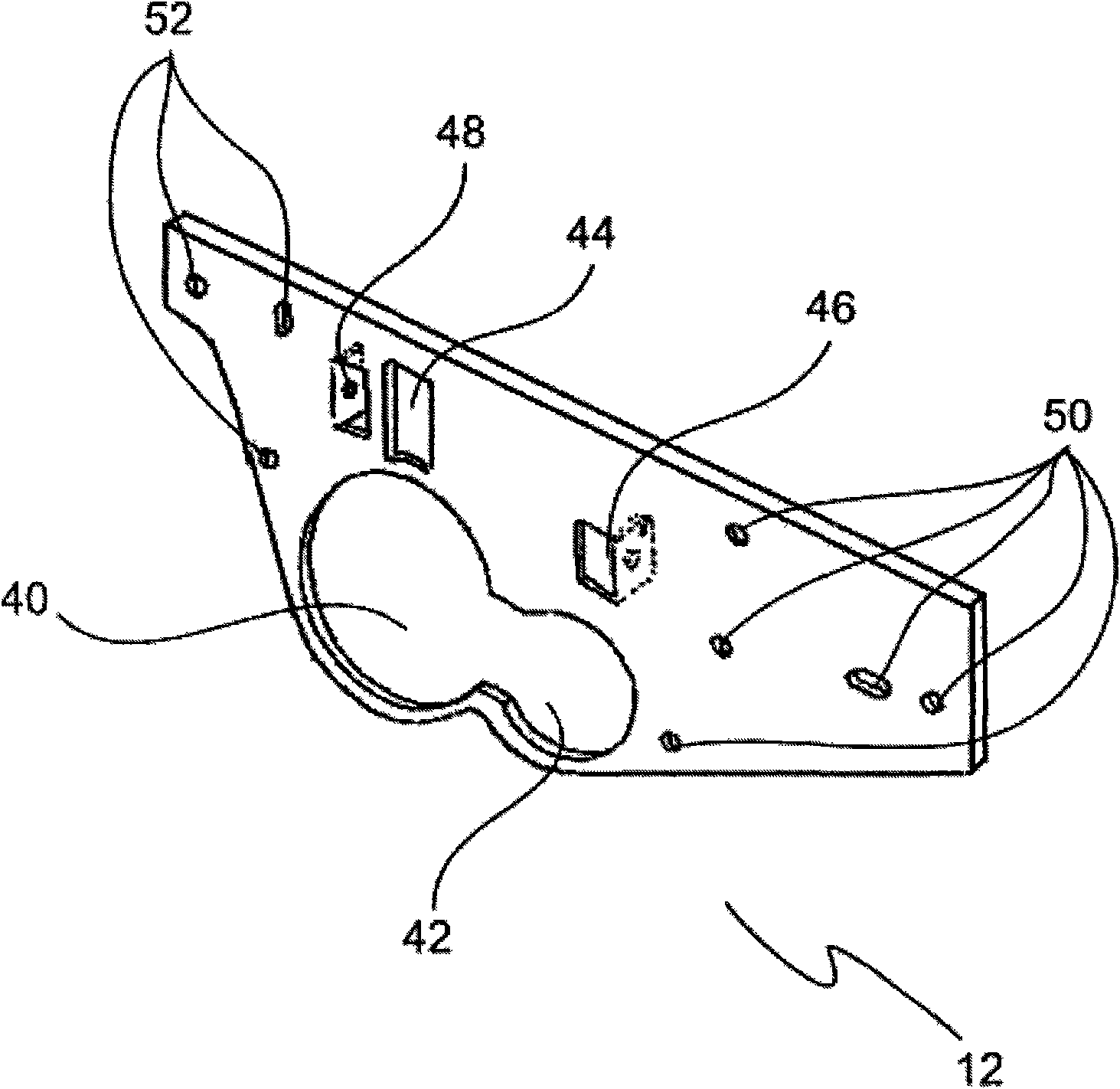

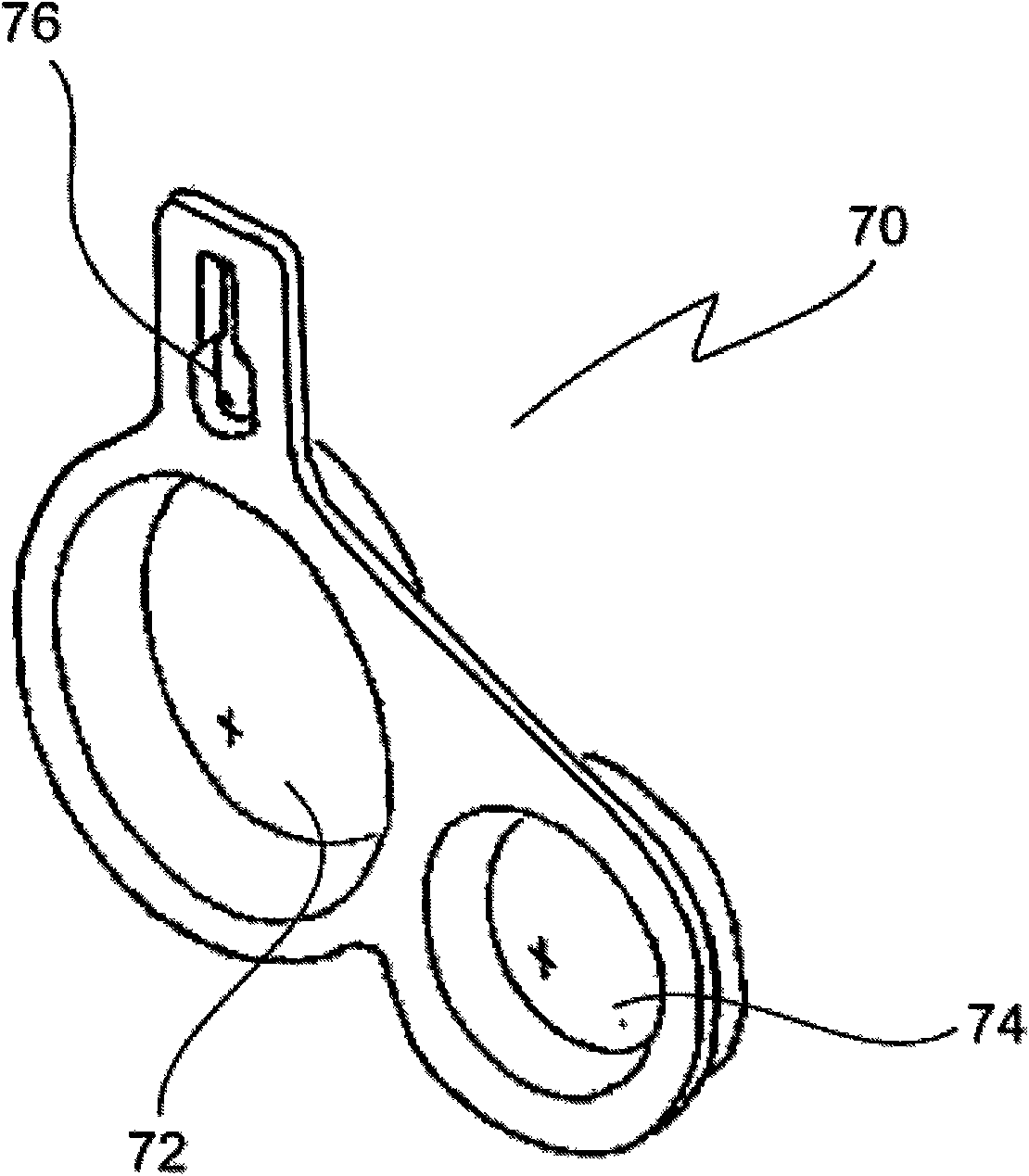

[0040] figure 1 Shown is a process cartridge 10 according to a first embodiment of the present invention. The processing cartridge 10 includes a first positioning element 12 and a second positioning element 14 respectively disposed at two ends in the longitudinal direction thereof. The following processing elements are extended between the first positioning element 12 and the second positioning element 14: photosensitive drum 16, developing roller 18, triboelectric blade (not shown), cleaning blade (not shown) and charging roll 20. In addition, the following housing elements are disposed between the first positioning element 12 and the second positioning element 14 : a toner cartridge 26 and a toner recovery unit 28 . Finally, a support plate 70 is removably connected to the first positioning element 12 , and there may be a second support plate (not shown) also removably connected to the second positioning element 14 .

[0041] The charging roller 20 is rotatable, and a sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com