Embedded circuit board radiating device and processing method of element

A technology of heat dissipation device and processing method, which is applied in the direction of circuit heat device, circuit, printed circuit connected with non-printed electrical components, etc., to achieve the effect of improving heat dissipation efficiency and solving heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

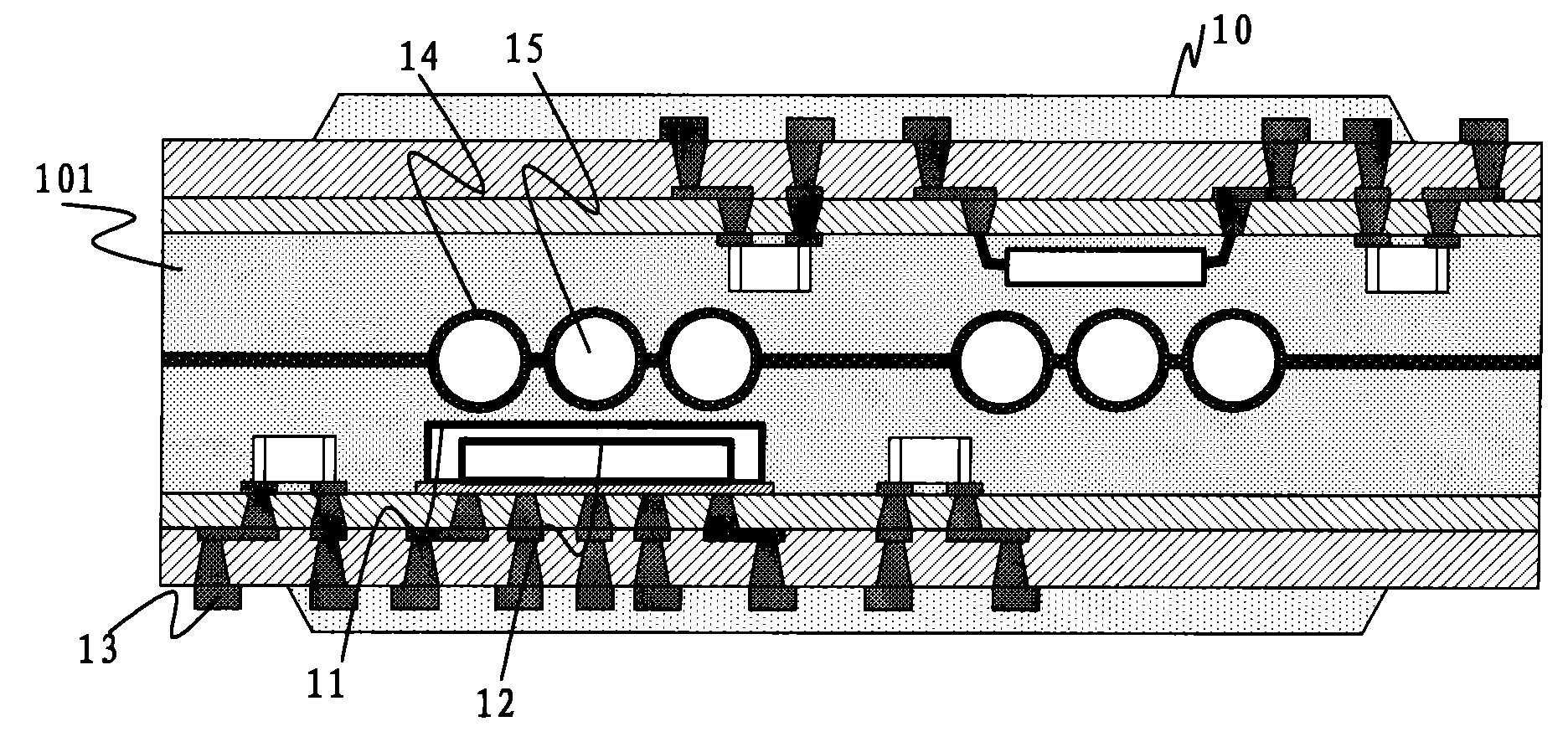

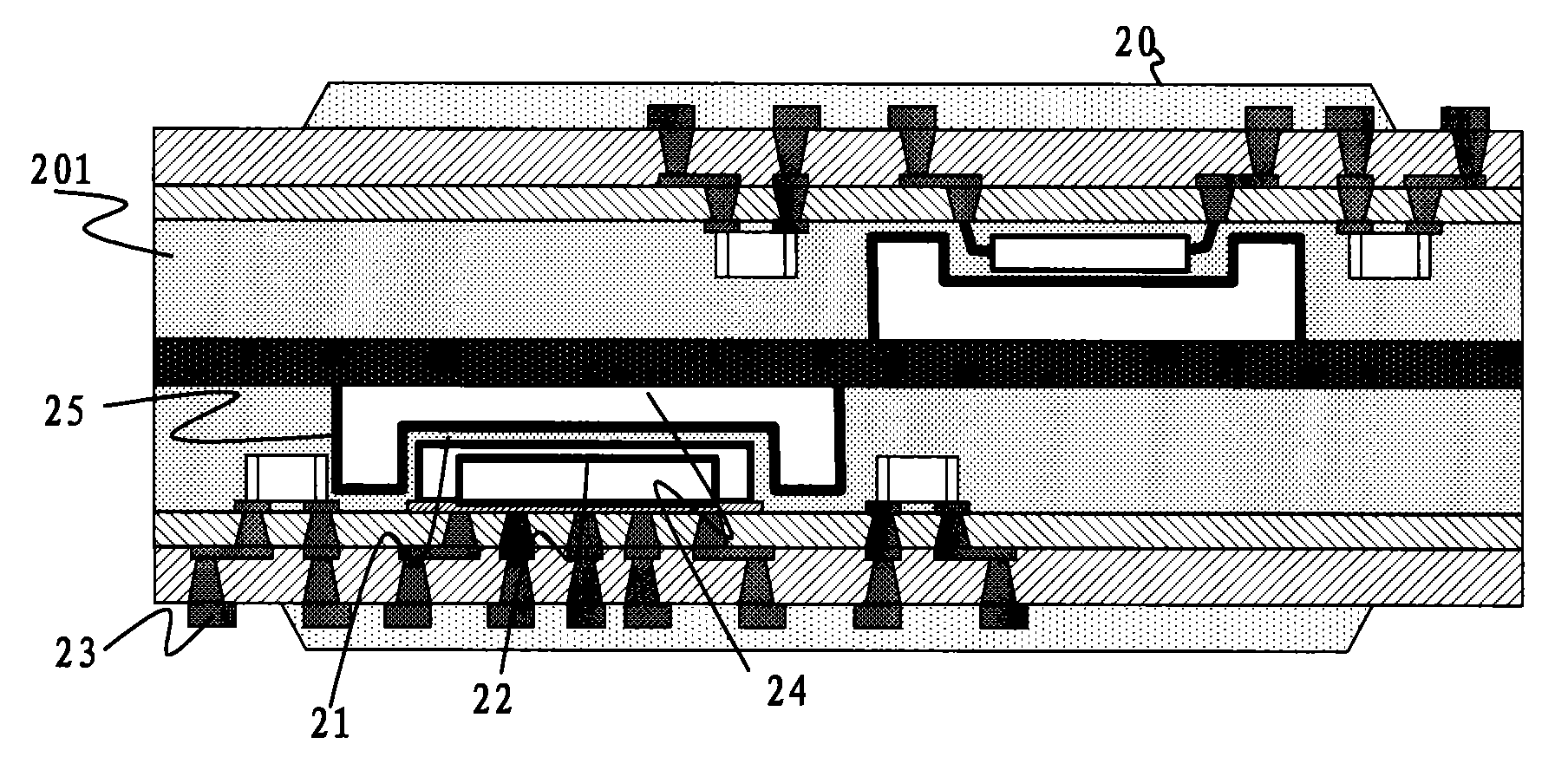

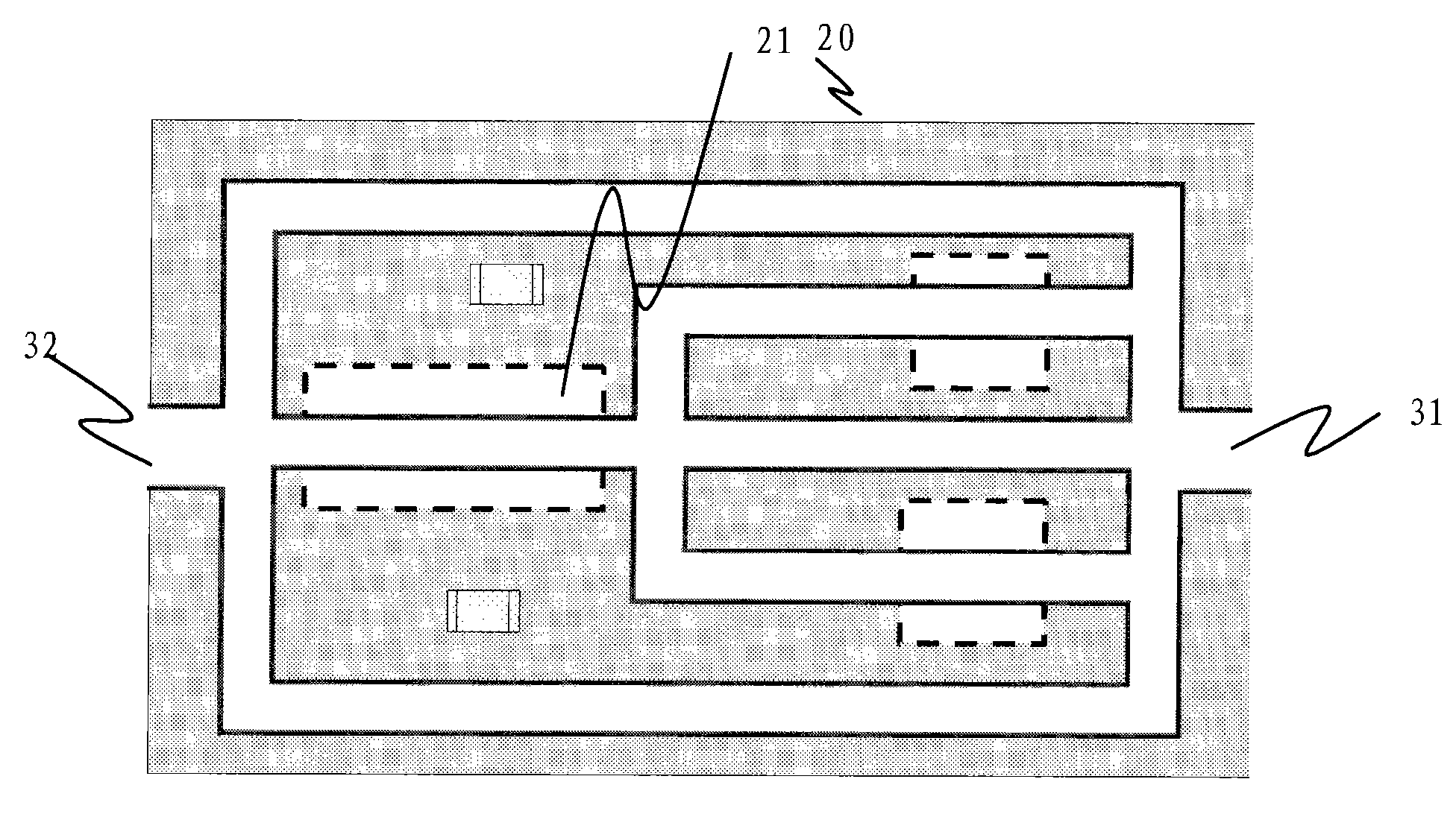

[0015] Embodiments of the present invention provide a device-embedded device-embedded circuit board heat dissipation method and a device-embedded circuit board heat dissipation device. A cooling groove is provided on the outer surface of the device cavity of the device-embedded circuit board. The cooling A heat pipe is laid inside the tank or the cooling tank forms a closed pipeline capable of containing circulating liquid, and the device is dissipated through the heat pipe or the circulating liquid takes away the heat of the device, so as to maximize the heat dissipation efficiency and solve the problem of buried devices in embedded devices. The heat dissipation problem of the embedded circuit board.

[0016] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] figure 1 The first device-embedded device-embedded circuit board heat dissipation device provided by the embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com