Clutch device of output shaft of gear-box for lawn-mower

A clutch device and output shaft technology, which is applied to mechanical drive clutches, clutches, harvesters, etc., can solve the problems of unsuitable structures with small radial dimensions and large radial dimensions of clamping rings, and achieve compact structure and improved performance. Reliable, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

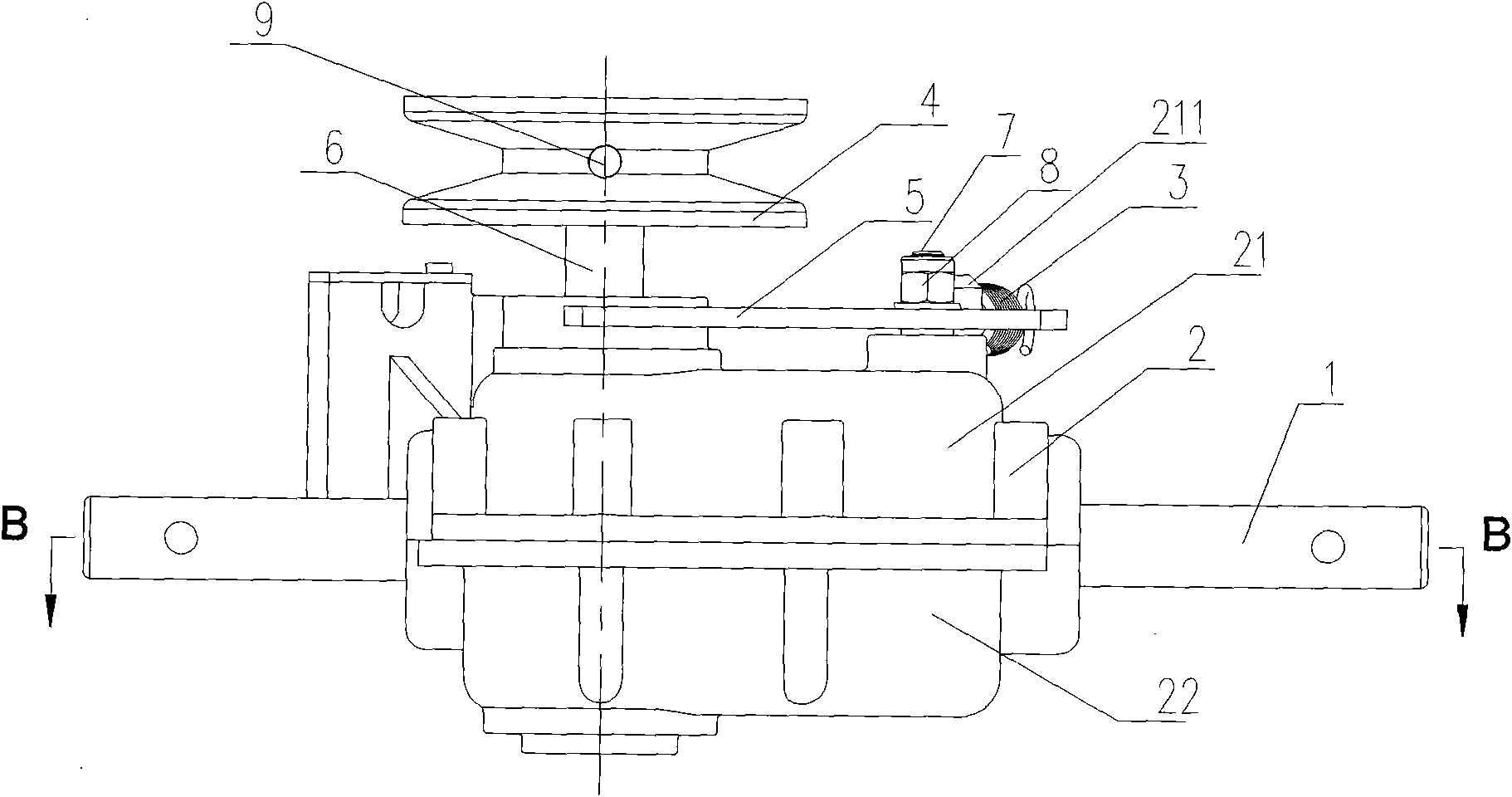

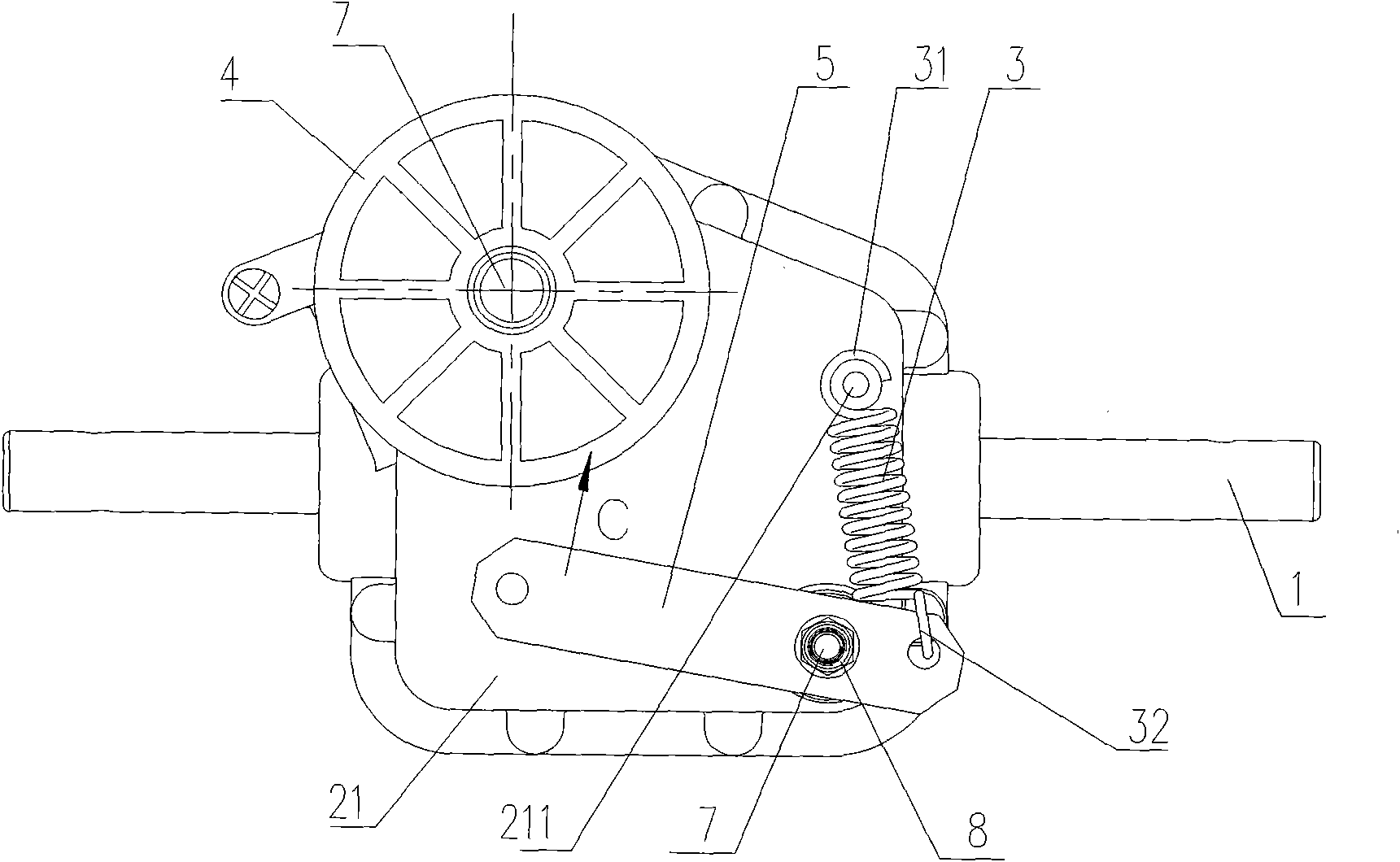

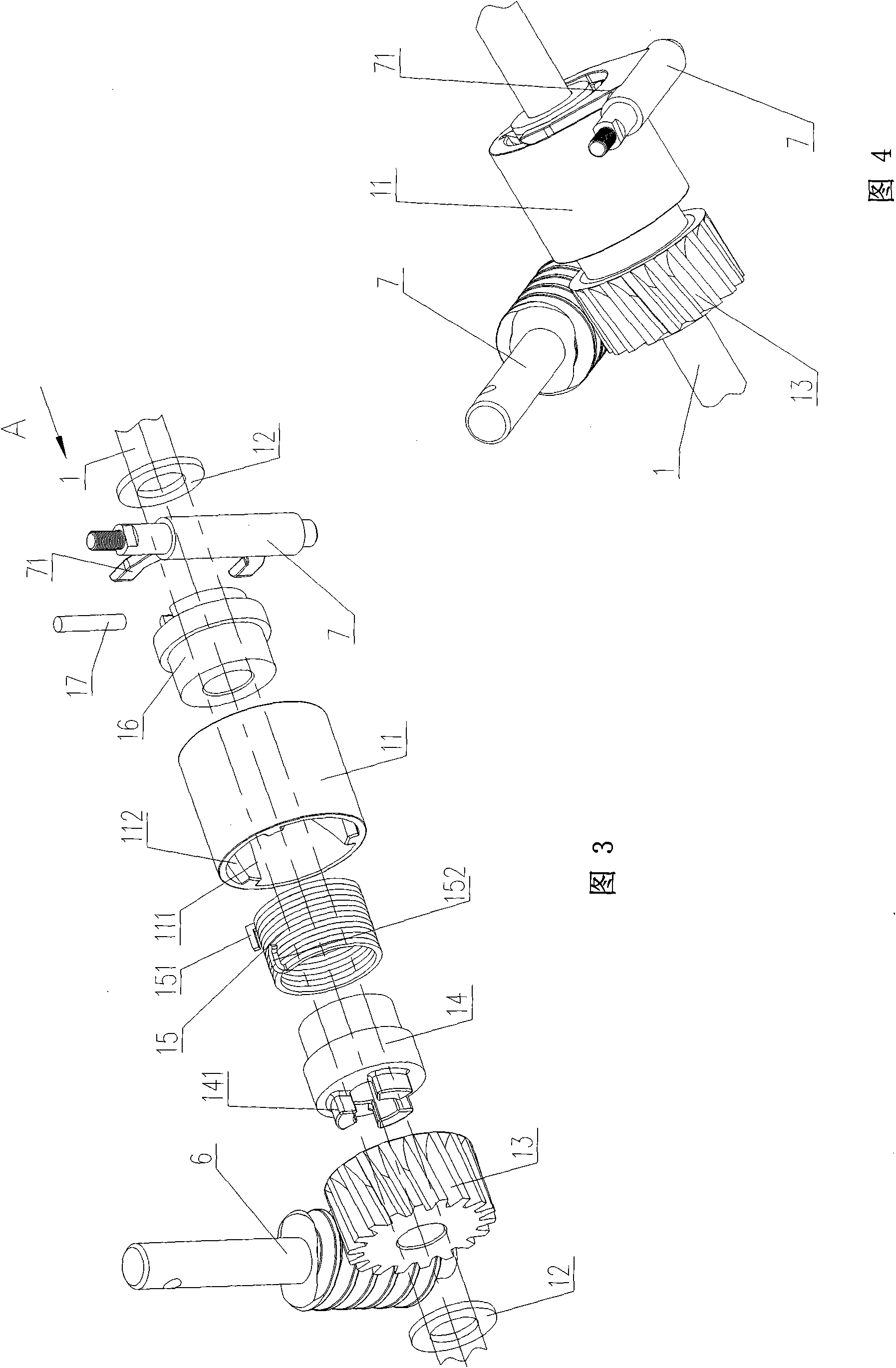

[0021] Such as Figure 1 to Figure 7 As shown, the present invention includes output shaft 1, gasket 12, worm screw 6, worm wheel 13, clutch separation shaft 7, extension spring 3, clutch swing arm 5, sliding sleeve 11, axle sleeve I 14, torsion spring 15, axle sleeve II 16. Elastic pin 17; spacer 12, worm gear 13, bushing I 14, torsion spring 15, bushing II 16 are sequentially set on the output shaft 1, and the outside of the spacer 12 is respectively provided with a The bearing seat 10, the output shaft 1 is supported on the box body 2 through the bearing seats 10 on both sides, the gasket 12 is respectively arranged between the bearing seat 10 and the worm wheel 13, the bearing seat 10 and the shaft sleeve II 16, and the sliding sleeve 11 Frequent axial movement acts as a stop back.

[0022] Such as image 3 , Figure 7 As shown, the torsion spring 15 is sleeved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com