Monitoring and control of a froth flotation plant

A foam flotation and foam technology, applied in flotation, chemical instruments and methods, solid separation, etc., can solve problems such as inability to overcome foam surface difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

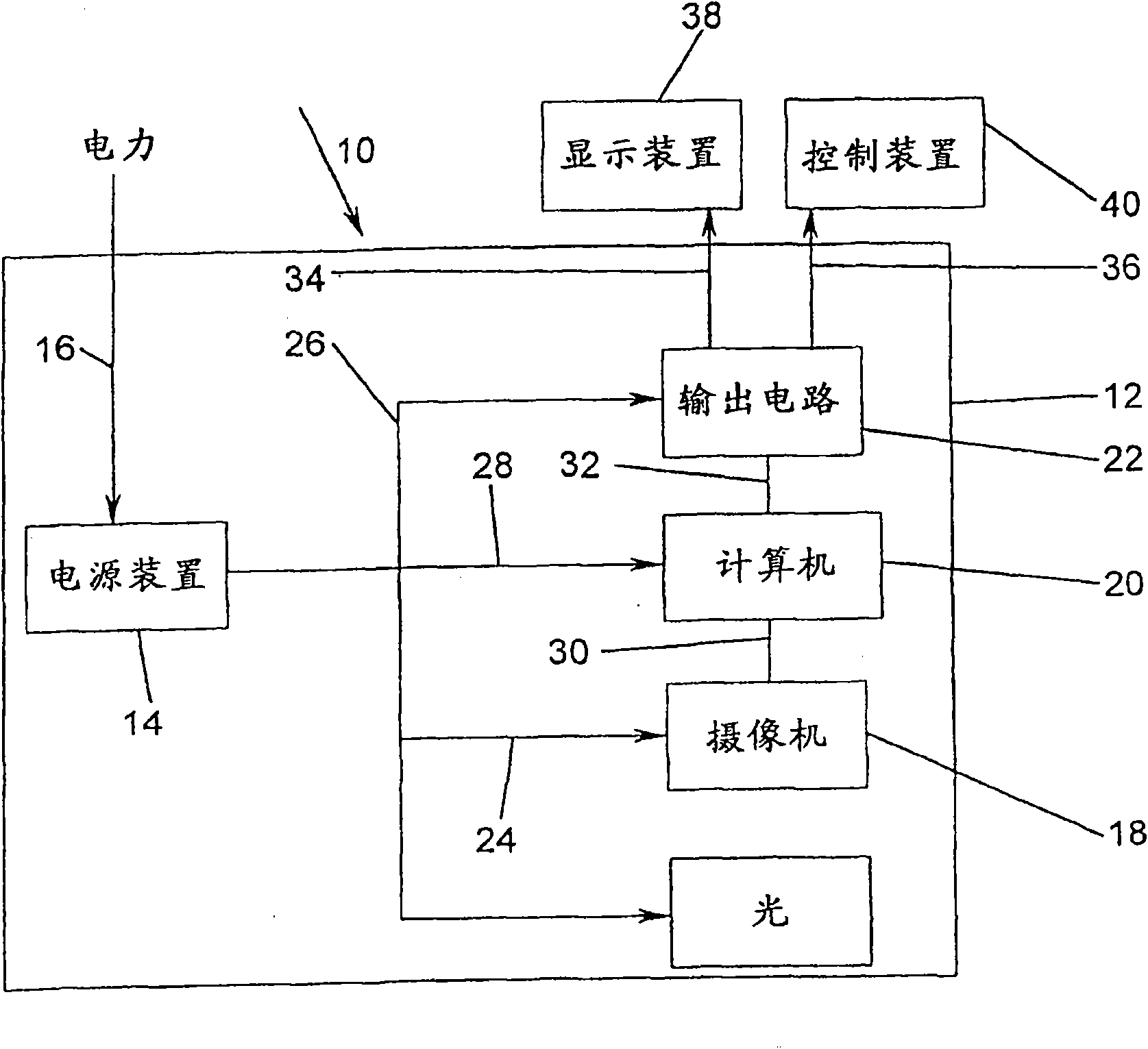

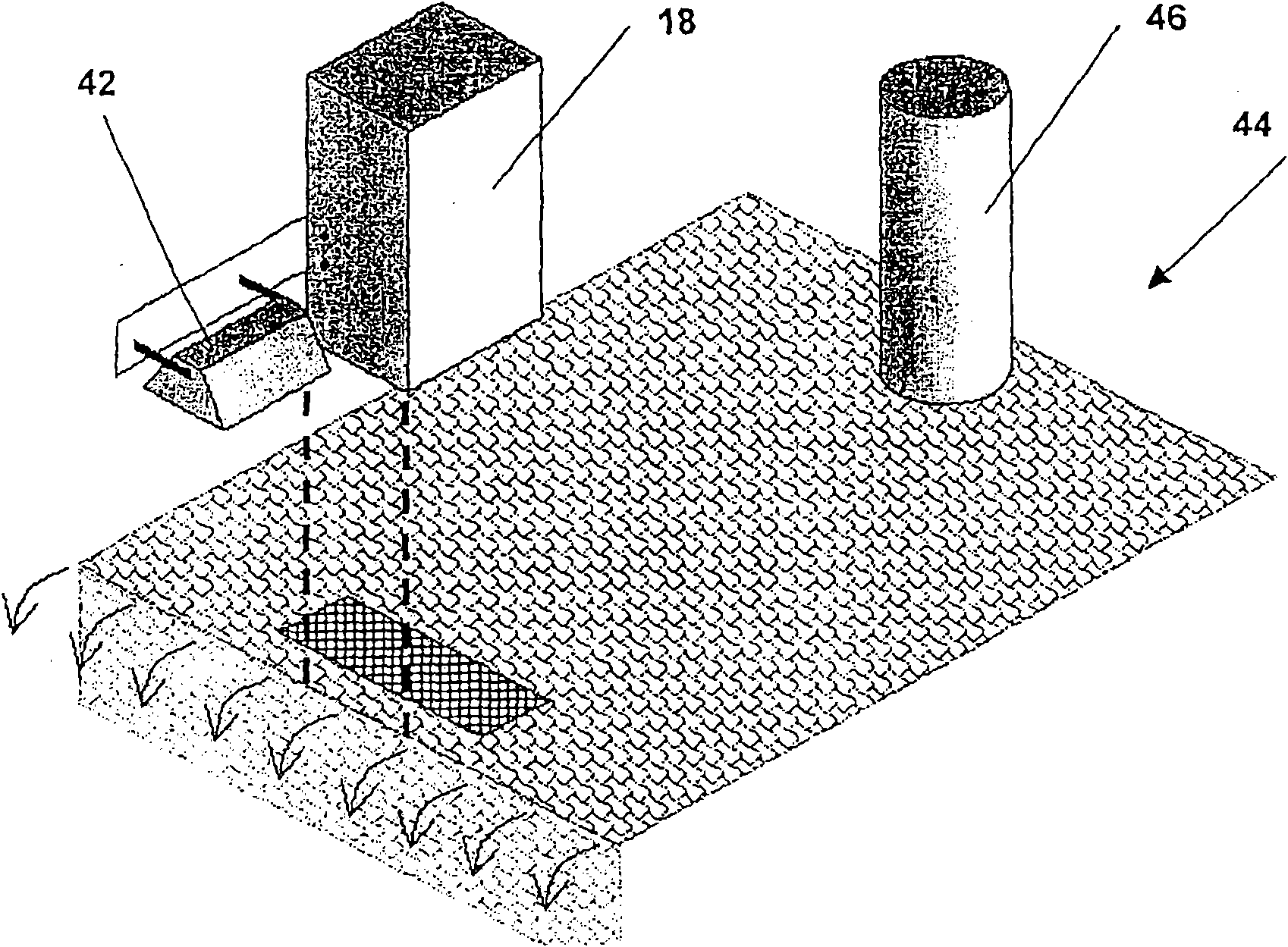

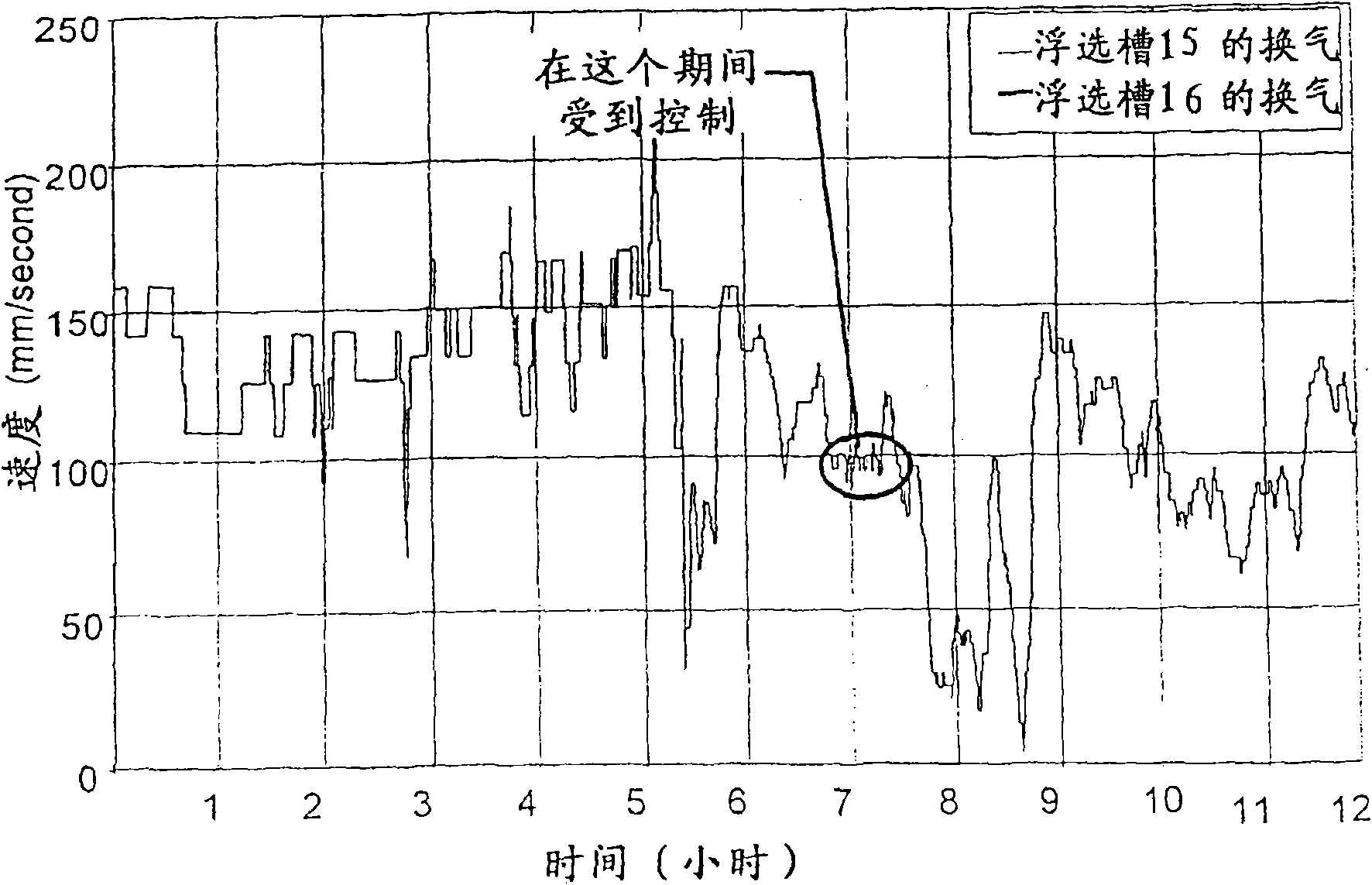

Embodiment Construction

[0026] The approach taken in accordance with the present invention is based on the premise that the purpose of using machine vision to improve the performance of flotation operations should be to provide a good alternative to conventional human vision and human problem-solving abilities. Thus, the present invention seeks to mimic the observation and intelligence of a trusted person. The advantage of this approach is that it simplifies the understanding of the technology by both the process technician and the plant staff by what is new to the plant staff.

[0027] The present invention modifies the conventional method of "characterizing foam" in order to "measure foam characteristics". Due to the fact that each flotation plant has different desired froth characteristics and different corrections for different deviations in order to achieve the desired flotation state, the old method of froth characterization encountered a great deal of opposition among plant employees . For a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com