Straddle carrier

A straddle vehicle and wheel technology, which is applied in the field of a straddle vehicle and straddle vehicle system, can solve the problems of inability to carry at the same time, cannot make full use of the transportation, etc., and achieve the effects of significant savings, increased storage density, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

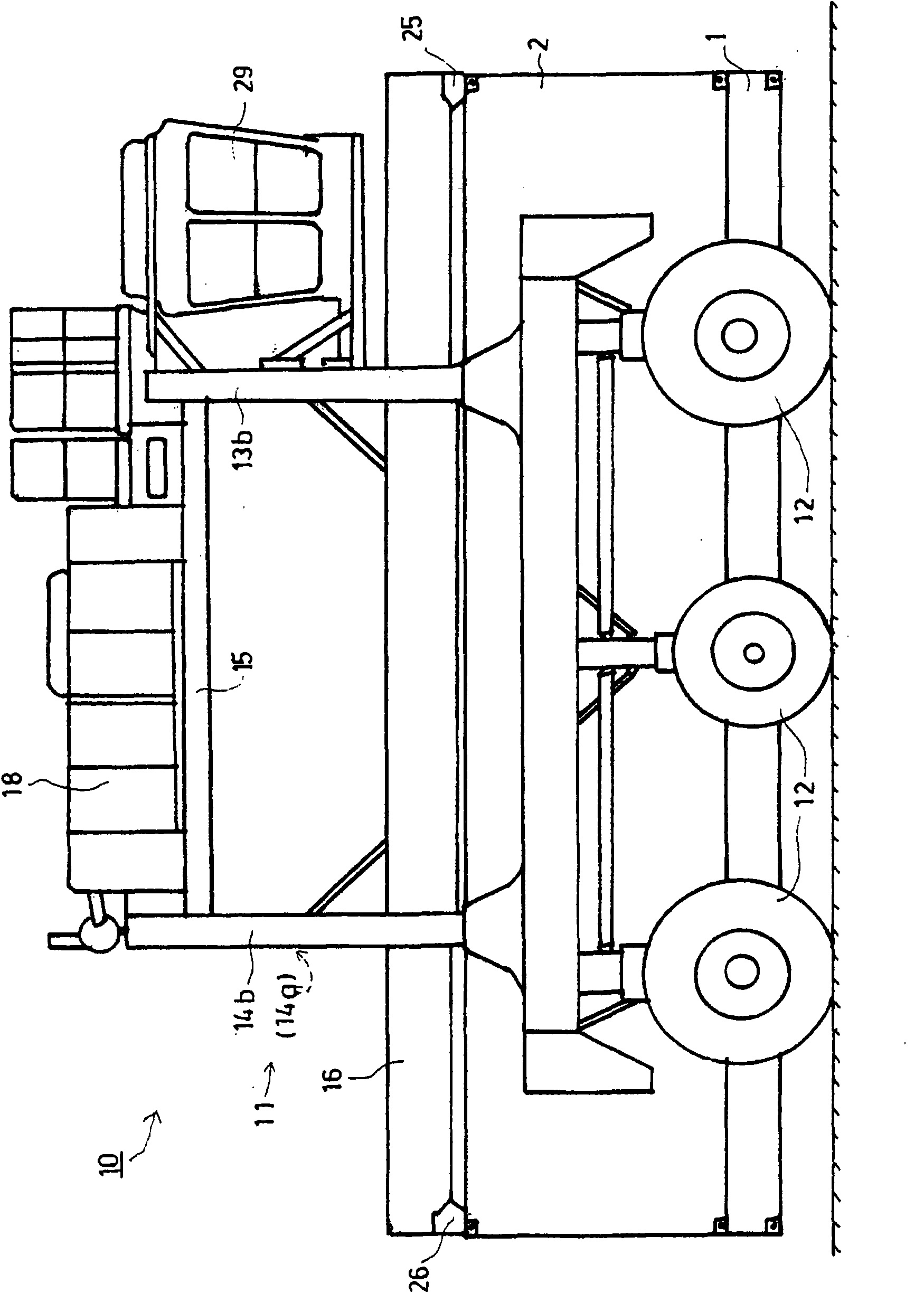

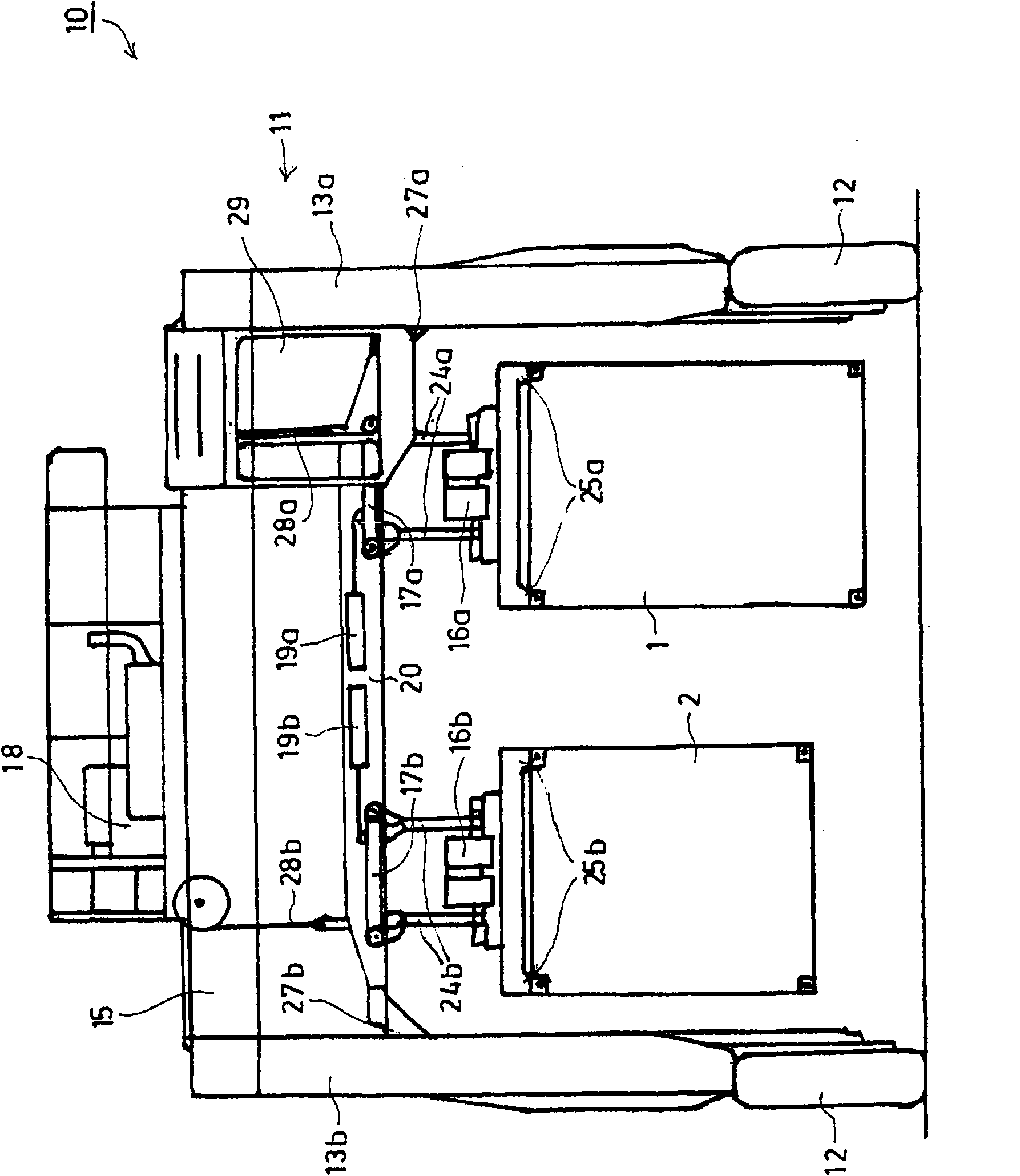

[0013] In the figures, the general reference numeral 10 denotes a straddle vehicle. The straddle carrier 10 comprises a mast body 11 comprising substantially vertical columns 13a, 13b, 14a, 14b and an upper frame body 15 connecting these columns at the top. On both sides of the straddle vehicle 10, wheels 12 supporting the mast body 11 are mounted at the lower ends of the pillars 13a, 13b, 14a, 14b. The driver's cab of the straddle vehicle 10 is designated by the reference numeral 29 in the drawing. As shown in the accompanying drawings, especially the figure 2 According to the structure of the straddle car of the present invention, the basic characteristics of the straddle car 10 are retained, but the door frame body 11 of the straddle car 10 according to the present invention is made wider compared with the prior art scheme, so that the door frame body pillar can Two parallel container hangers 16, 16a, 16b are assembled between 13a, 13b, 14a, 14b, so that the straddle veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com