Residue, water and oil separator

An oil separator and slag collecting tank technology, which is applied in liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor removal effect, inability to remove, destroying sewage biological treatment and purification methods, etc. separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

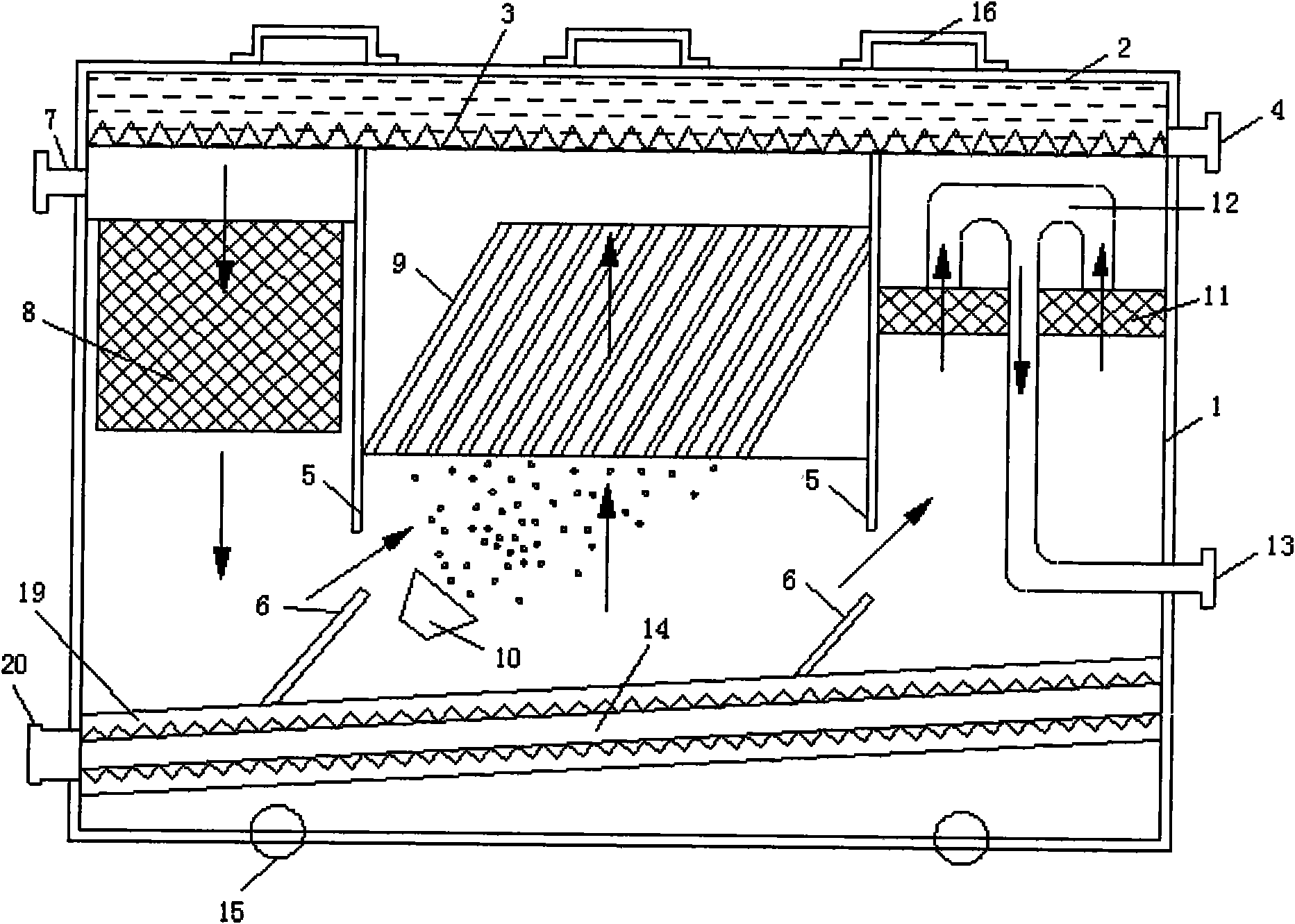

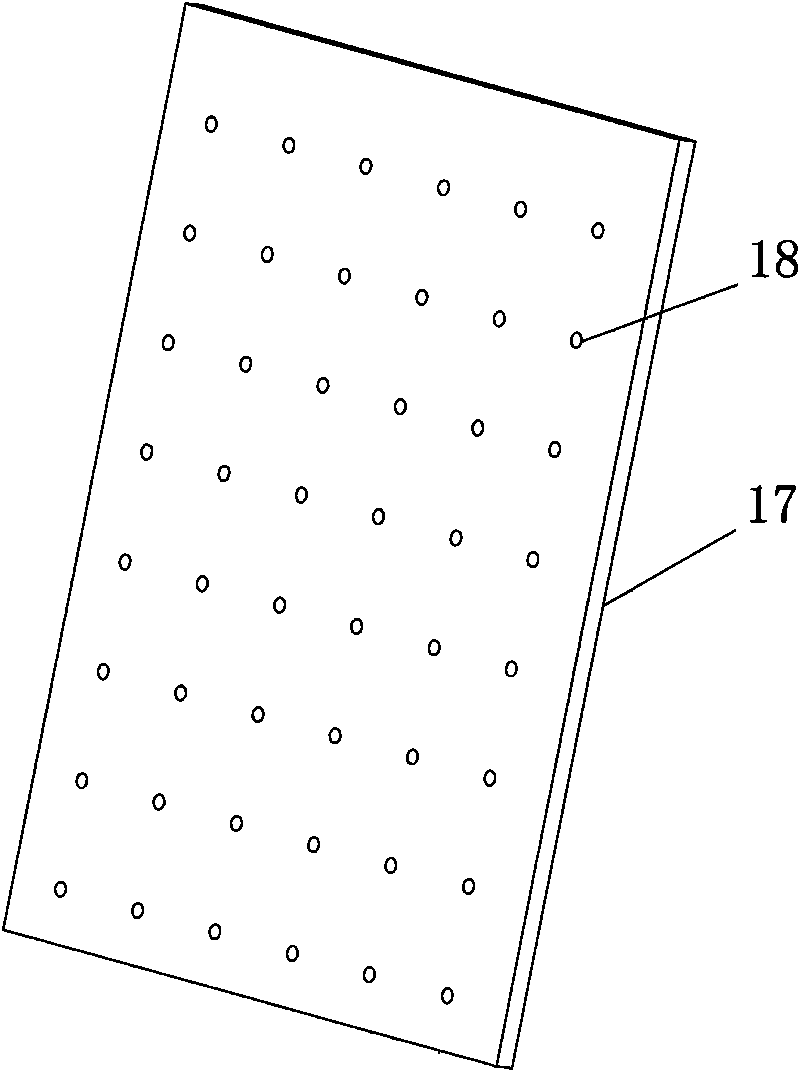

[0033] Such as figure 1 The slag, water and oil separator shown includes a box body 1 and a cover plate 2 covered on the box body 1. The upper inner wall of the box body 1 is provided with a zigzag overflow weir 3, and the upper outer side of the box body 1 There is an oil outlet 4, and the box body 1 is divided into three compartments by two partitions 5, and two diversion and water distribution plates 6 are provided under the two partitions 5; a sewage water inlet 7 is provided on the side of the first compartment , the upper part of the first grid is provided with a slag separation screen to lift blue 8, the upper part of the second grid is provided with a shallow bed 9, and the lower part of the shallow bed 9 is provided with a micro-bubble nozzle 10, and the micro-bubble nozzle 10 is externally connected to an air pump. A fiber adsorption bed 11 is arranged above the third compartment, and a water outlet pipe 12 is arranged above the fiber adsorption bed 11, and the water...

Embodiment 2

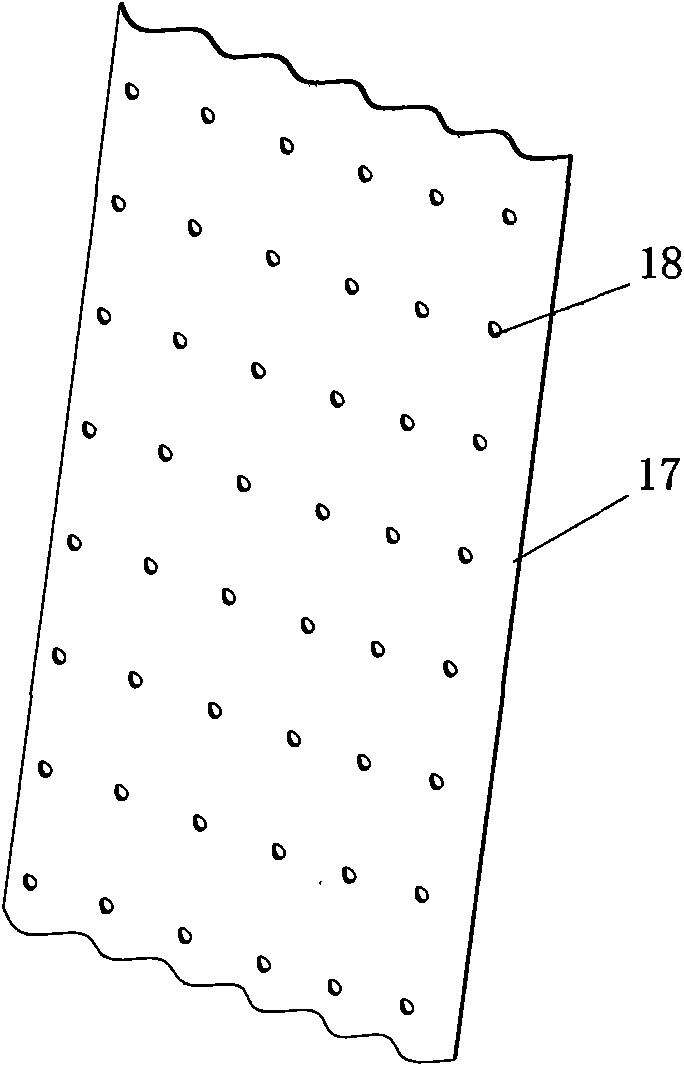

[0040] This embodiment is similar in structure to Embodiment 1, except that the following technical features are different: as image 3 As shown, the shallow plate 17 is a corrugated panel.

Embodiment 3

[0042] This embodiment is similar in structure to Embodiment 1, except that the following technical features are different: as Figure 4 As shown, the shallow plate 17 is composed of a row of circular tubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com