Technology of treating coking wastewater by biomembrance process

A technology of coking wastewater and biofilm method, applied in sustainable biological treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. Complete sewage treatment, saving infrastructure costs, and small aeration volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

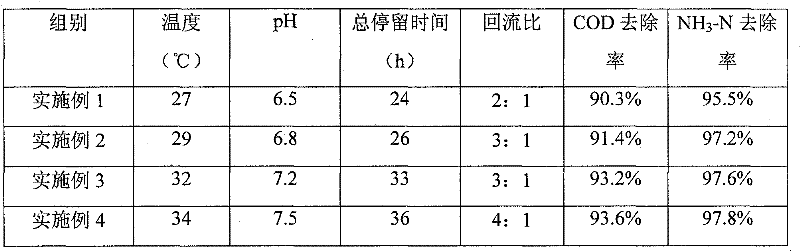

Examples

Embodiment Construction

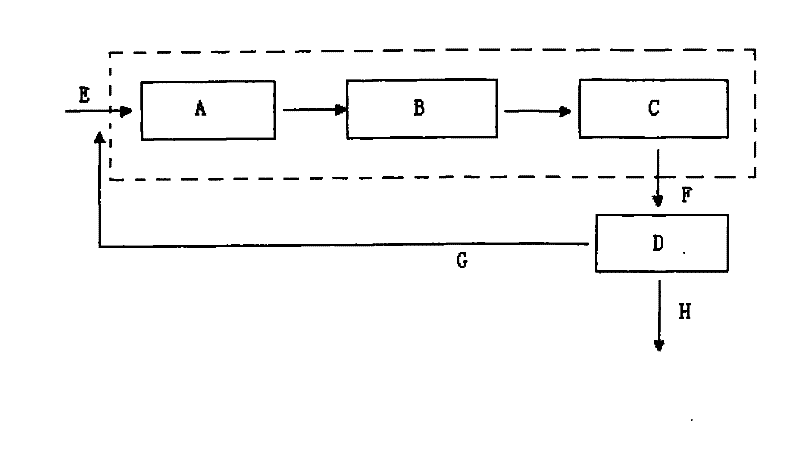

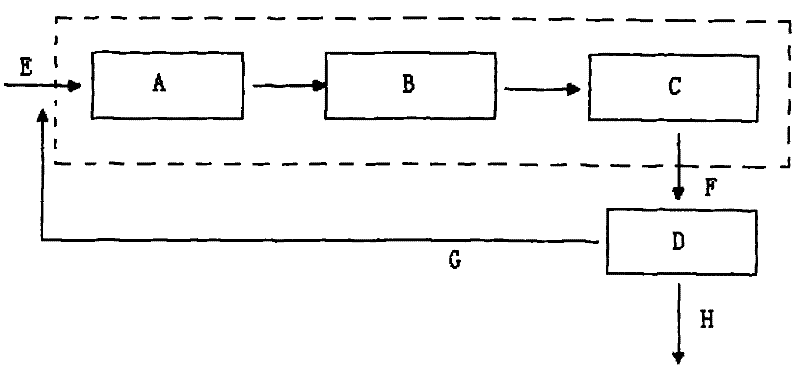

[0027] The process of treating coking wastewater by the anaerobic biological filter + aerobic biological fluidized bed + anoxic biological filter disclosed in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] The process is shown in Figure 1, which is divided into the film-hanging period and the formal operation period.

[0029] During the film hanging period, first put the biofilm carrier into the reactor, the carrier in the anaerobic biological filter and the aerobic biological fluidized bed is a suspended biological carrier made of polypropylene, and the carrier is a hollow cylinder with a cross partition inside. The surface is corrugated and uneven, with a length of 10-15mm and a diameter of 8-12mm. The volume of the carrier in the anaerobic biological filter is 60%-80% of the reactor volume, and the volume of the carrier in the aerobic biological fluidized bed The added volume is 30%-40% of the reactor volume. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com