Device and method for printing and dyeing wastewater treatment

A technology for printing and dyeing wastewater and treatment methods, which is applied in the direction of textile industry wastewater treatment, multi-stage water treatment, chemical instruments and methods, etc., can solve problems such as poor treatment effect, and achieve reliable operation of the device, good treatment effect, and economical rationality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

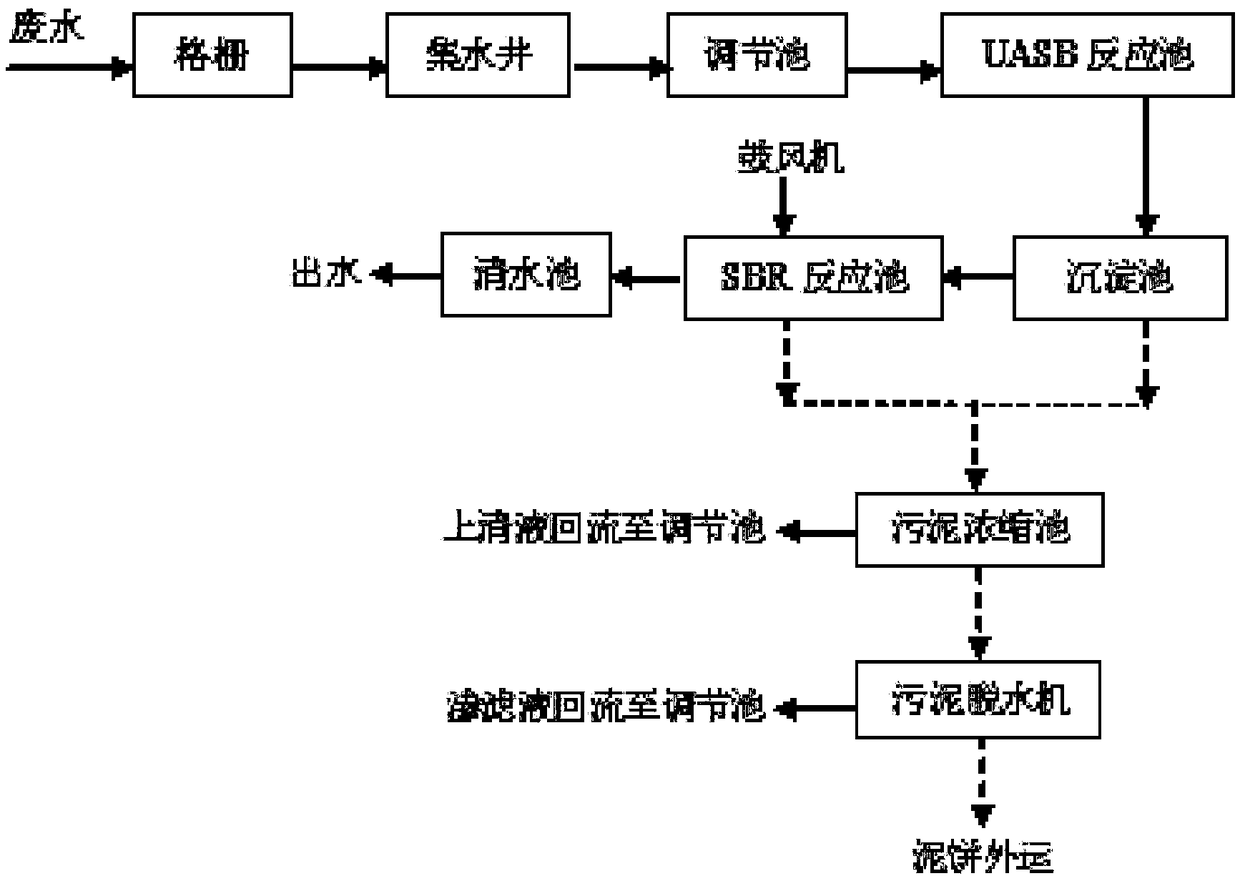

[0017] A printing and dyeing wastewater treatment device, such as figure 1 , including grids, water collection wells, regulating tanks, UASB reaction tanks, sedimentation tanks, SBR reaction tanks and clean water tanks connected in sequence. The clean water tanks are connected to the regulating tanks through transcendent pipes, and the sedimentation tanks and SBR reaction tanks are connected to the sludge thickening tanks. , the sludge thickening tank is connected with the sludge dewatering machine and the regulating tank respectively, and the sludge dewatering machine is connected with the regulating tank.

[0018] in:

[0019] The grid gap of the grid is 5mm;

[0020] The UASB reaction tank contains a large number of hydrolytic bacteria and acid-producing bacteria. The pool is equipped with a combined filler, and the microorganisms grow on the filler. The number of UASB reaction tanks is 2, used in series, and a three-phase separator is installed in the tank;

[0021] The ...

Embodiment 2

[0032] A printing and dyeing wastewater treatment device, such as figure 1 , including grids, water collection wells, UASB reaction tanks, sedimentation tanks, SBR reaction tanks and clear water tanks connected in sequence.

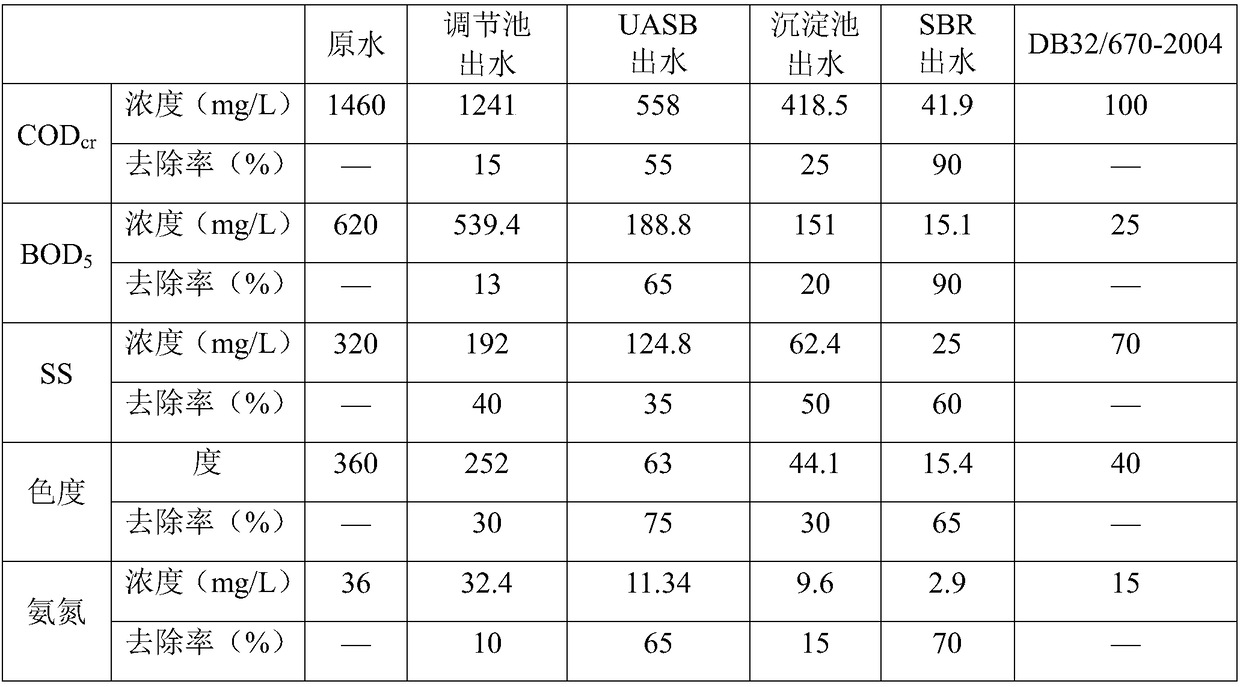

[0033] The above-mentioned device is used to treat a certain printing and dyeing wastewater, and the water volume of the wastewater is 1200m 3 / d, the relevant index of water quality is: COD cr 1560mg / L, BOD 5 600mg / L, SS 280mg / L, chroma 300, ammonia nitrogen 30mg / L.

[0034] The printing and dyeing wastewater is passed through the grid to remove large floating matter and suspended particles; then it enters the UASB reaction pool through the water collection well to improve the biodegradability of organic matter and remove some organic pollutants and chroma. The residence time is 12h; the UASB reaction pool The effluent enters the sedimentation tank to further remove suspended substances; the effluent of the sedimentation tank enters the SBR reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com