Oilfield produced water treatment device

A treatment device and technology for produced water, which is applied in water/sewage treatment, flotation water/sewage treatment, multi-stage water/sewage treatment, etc. It can solve the problems of inability to adapt to raw water quality fluctuations, unsatisfactory treatment effects, and complicated treatment methods, etc. problem, to achieve fast connection, fast commissioning, and guaranteed processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

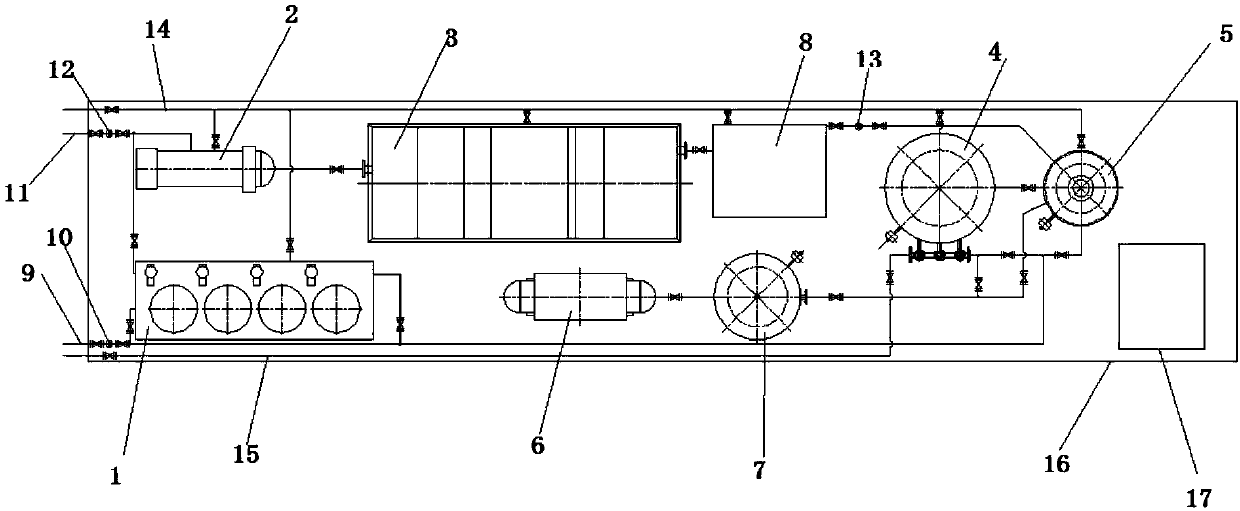

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] A kind of oilfield production water treatment device of the present invention, as figure 1 As shown, it includes a dosing device 1 , a cyclone separator 2 , an air flotation device 3 , an oil-water separation filter 5 and a sintered tube fine filter 4 which are sequentially connected by pipelines.

[0020] It also includes an air source system, which is respectively connected to the sintered tube fine filter 4 and the oil-water separation filter 5 through pipelines, and the air source system provides a power source for the pneumatic valve system.

[0021] It also includes a container 16, which is heat-insulated to adapt to cold and harsh conditions; dosing device 1, cyclone separator 2, air flotation device 3, sintered tube fine filter 4, oil-water separation filter 5 , air compressor 6 and gas storage tank 7 are all installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com